Control method of plasma dry etching process

A plasma and dry etching technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems affecting the production capacity of the machine and increase the cost, so as to reduce the process cost, improve the production capacity of the machine, and accurately and the effect of stabilizing the control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

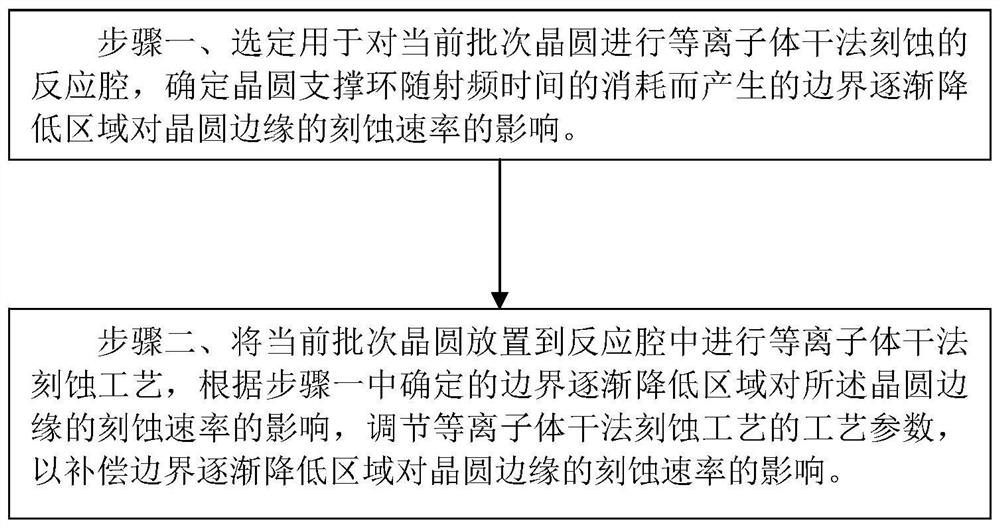

[0033] The method of the embodiment of the present invention is obtained on the basis of analyzing the technical problems existing in the existing method. Before introducing the technical solution of the method of the embodiment of the present invention in detail, the existing technical problems are described as follows:

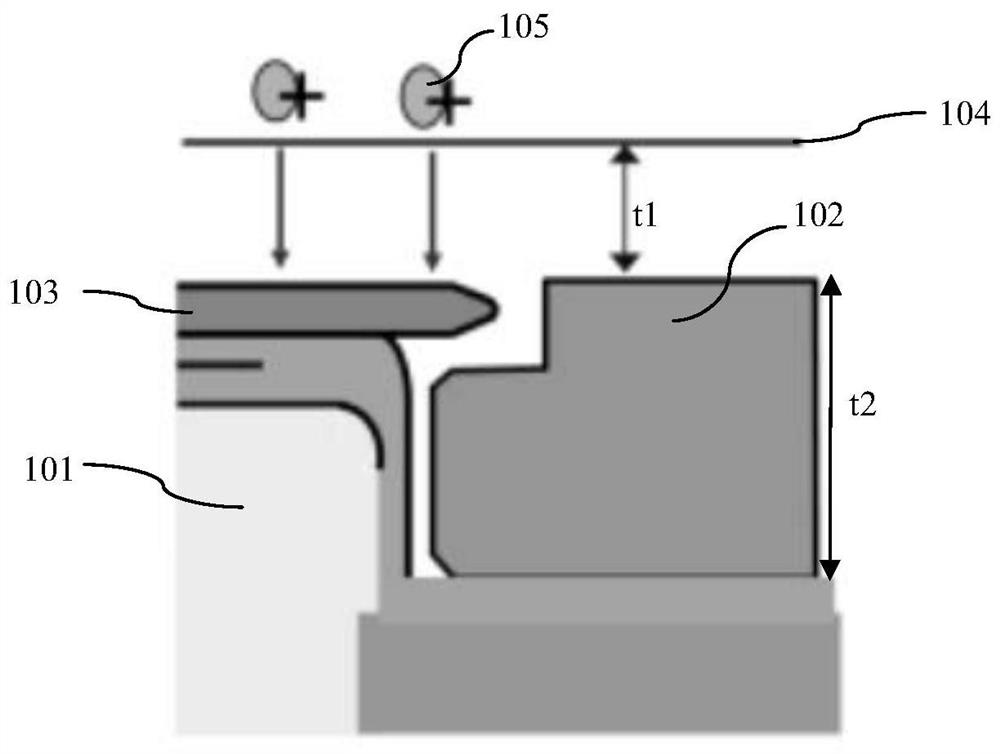

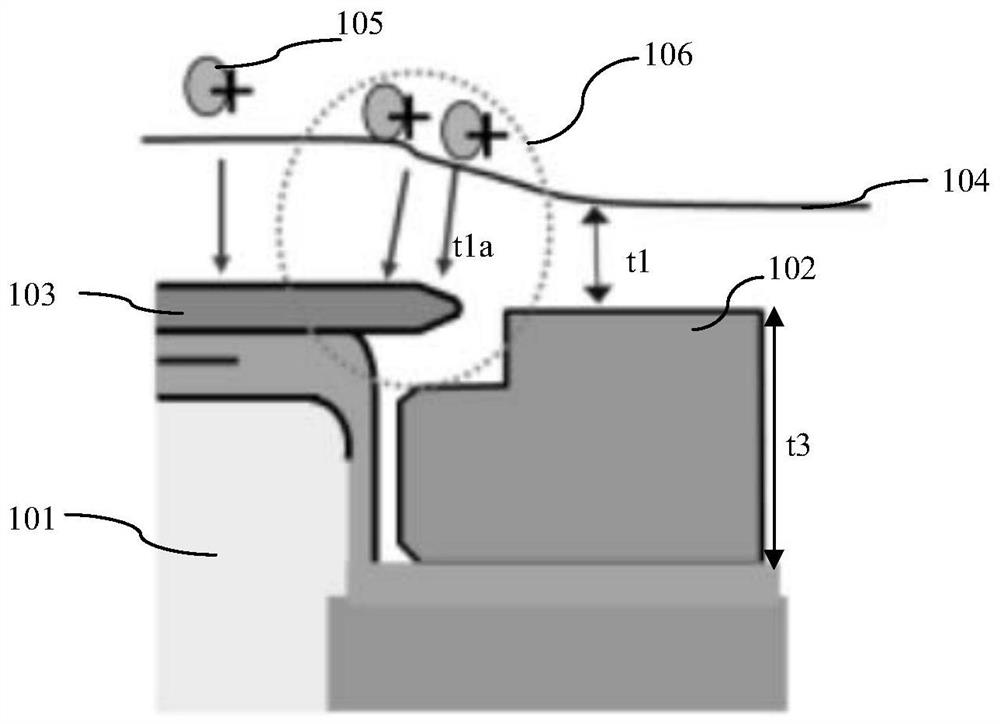

[0034] Such as Figure 1A Shown is a schematic diagram of the structure of the plasma sheath boundary when the wafer support ring is just replaced in the reaction chamber of the plasma dry etching process; the reaction chamber includes a wafer placement area 101 and a wafer placement area 101. The wafer support ring 102 on the peripheral side, the wafer 103 is placed on the wafer placement area 101, and the wafer placement area 101 is provided with an electrostatic adsorption plate, and the wafer 103 is fixed by the electrostatic adsorption plate.

[0035] The reaction chamber also includes a radio frequency source. After the process gas is introduced, a plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com