Preparation method of carbon nanotube film, functionalized carbon nanotube film and application of functionalized carbon nanotube film in electrocatalytic hydrogen production

A carbon nanotube film and functionalization technology, which is applied in the direction of carbon compounds, chemical instruments and methods, electrodes, etc., can solve the problems of high price, and achieve the effects of easy and stable storage, large industrial application prospects, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

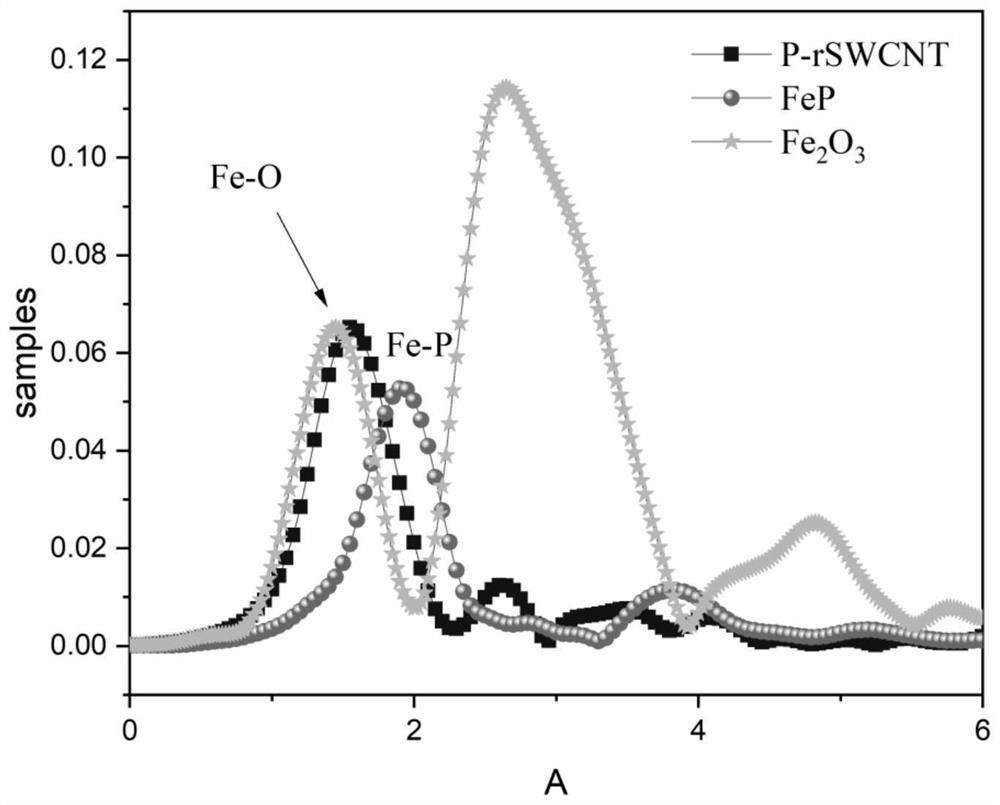

[0029] The invention provides a method for preparing a carbon nanotube film, comprising the following steps:

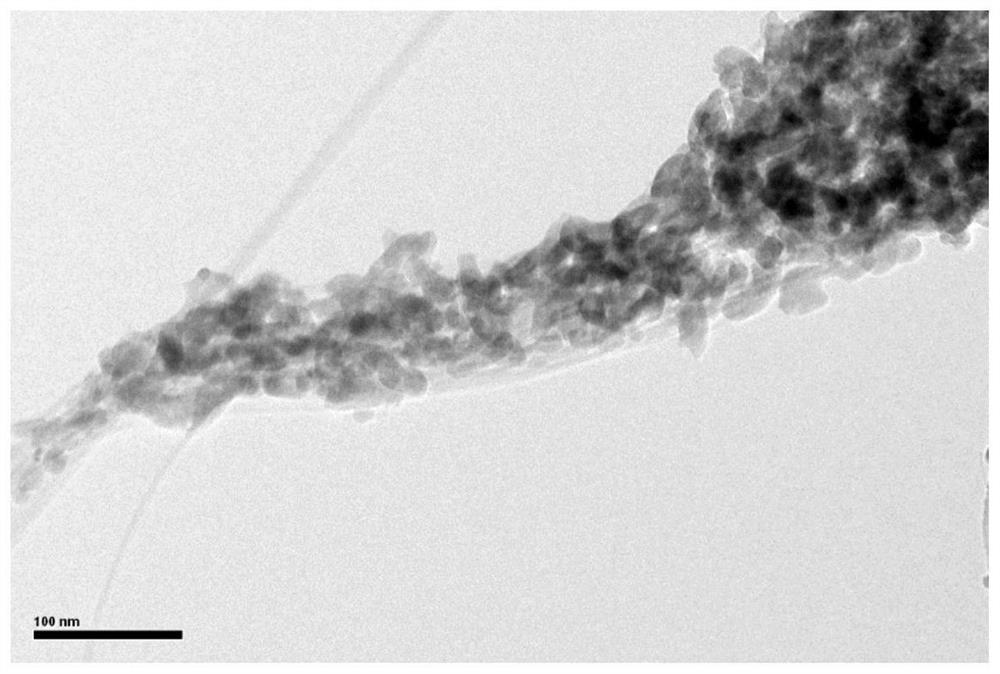

[0030] Using ferrocene and sulfur powder with a mass ratio of (90-95): 1 as a catalyst, the catalyst is first heated to a temperature of 95-100°C, and then methane gas is used as a raw material gas, in an argon atmosphere, the Under the action of the catalyst, the temperature is raised to 1000-1100° C. for reaction deposition for a certain period of time, and the crude carbon nanotube film containing iron is obtained by peeling off.

[0031] Based on some problems in the current preparation methods of carbon-based electrocatalysts, the present invention first synthesizes a crude carbon nanotube film, and then functionalizes it, which is expected to obtain a cheap and flexible electrocatalytic film for industrial large-scale hydrogen production .

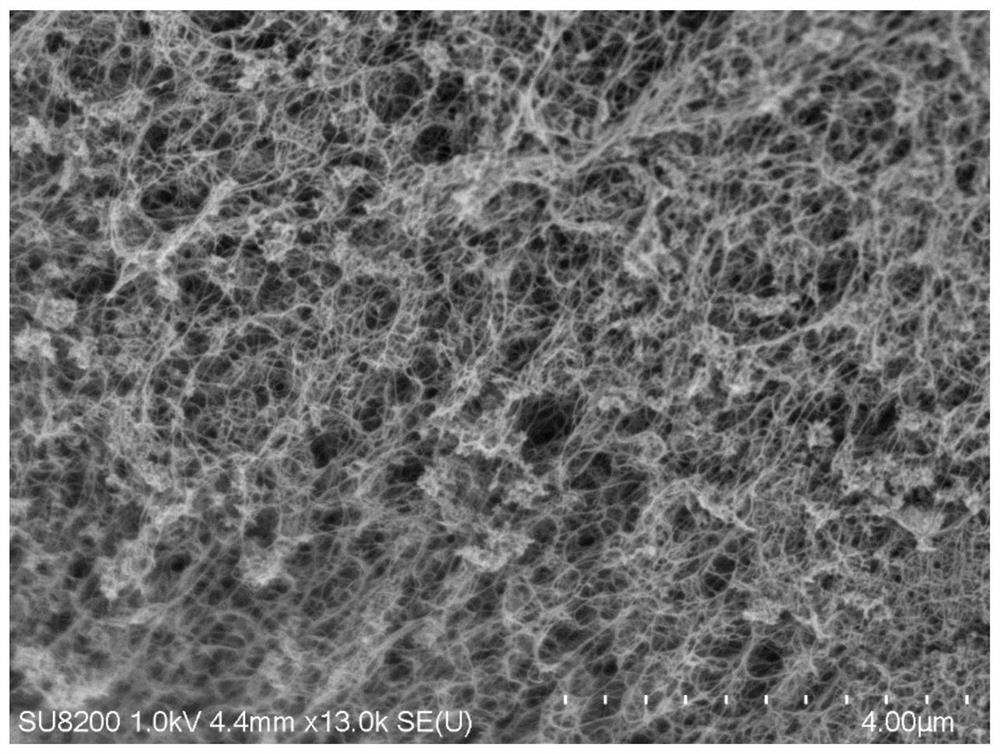

[0032] The preparation of carbon nanotubes by chemical vapor deposition (CVD) is a method of catalytically decomposing ca...

Embodiment 1

[0051] a. First prepare the catalyst for carbon tubes: mix ferrocene and high-purity sulfur powder evenly at a mass ratio of 93:1, and grind them in a mortar for 30 minutes. Then prepare the carbon nanotube film:

[0052] Using a double-layer quartz tube, weigh an appropriate amount of the catalyst obtained above and put it on the front end of the quartz tube, then purge it with argon for 15 minutes, and start the temperature program at a rate of 35°C / min. When the programmed temperature reaches 1050°C, start heating the catalyst part at the front end of the quartz tube and keep the temperature at 100°C. When the temperature program raises the temperature of the quartz tube to 1100°C and the catalyst heating temperature is also stable to 100°C, start to feed high-purity CH 4 Gas (4.5 sccm). At this temperature, continue to pass CH 4 After the gas was maintained for 2 hours, the methane gas was turned off, but the Ar gas atmosphere was maintained by continuously feeding the ...

Embodiment 2

[0063] This embodiment is different from Example 1 in that: the NaH 2 PO 2 ·H 2 O quality is changed into 1.25g; Others are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com