Processing technology for improving peeling rate of aleurone layer and wheat bran layer in wheat processing

A wheat cortex and processing technology, which is applied in food ultrasonic treatment, grain treatment, food drying and other directions, can solve the problems of loss of nutrients, increase of by-products, reduction of utilization rate, etc., to enhance nutrition and quality, reduce bonding strength, The effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

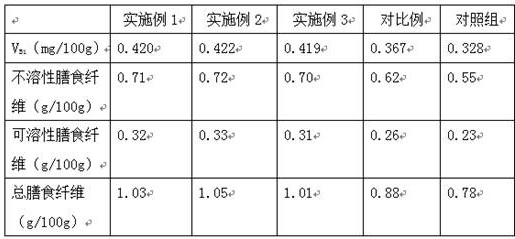

Examples

Embodiment 1

[0015] A processing technology for improving the peeling rate of aleurone layer and wheat cortex in wheat processing, the specific technology is as follows:

[0016] 1) According to the mass volume ratio of cornstarch and deionized water is 1:5g / mL, put the weighed cornstarch in a container, add deionized water to stir evenly and adjust the pH to 4.5, 400W ultrasonic treatment for 15min, place in Preheat in a water bath at 52°C for 10 minutes, then add α-amylase and glucoamylase according to 5.5% and 1.3% of the mass of cornstarch. The starch solution was vacuum filtered, washed with deionized water, filtered, and freeze-dried at -20°C for 20 hours to obtain porous starch;

[0017] 2) According to the mass-volume ratio of 1:100g / mL, add the weighed chitosan into 0.09M hydrochloric acid solution, and fully stir in an oil bath at 103°C to obtain acid-degraded chitosan with a viscosity-average molecular weight of 100KDa. Standby, according to the mass ratio of acid-degraded chit...

Embodiment 2

[0021] A processing technology for improving the peeling rate of aleurone layer and wheat cortex in wheat processing, the specific technology is as follows:

[0022] 1) According to the mass volume ratio of cornstarch to deionized water is 1:8g / mL, put the weighed cornstarch in a container, add deionized water to stir evenly and adjust the pH to 5.0, 450W ultrasonic treatment for 18min, place in Preheat in a water bath at 53°C for 12 minutes, then add α-amylase and glucoamylase according to 5.8% and 1.5% of the mass of corn starch, and after 25 hours of enzymolysis reaction in a constant temperature water bath, inactivate the enzyme activity to terminate the reaction. Vacuum suction filtration of the starch solution, washing with deionized water, suction filtration, and freeze-drying at -25°C for 23 hours to obtain porous starch;

[0023]2) According to the mass-volume ratio of 1:110g / mL, add the weighed chitosan into 0.093M hydrochloric acid solution, and fully stir in an oil...

Embodiment 3

[0027] A processing technology for improving the peeling rate of aleurone layer and wheat cortex in wheat processing, the specific technology is as follows:

[0028] 1) According to the mass volume ratio of cornstarch and deionized water is 1:10g / mL, put the weighed cornstarch in a container, add deionized water to stir evenly and adjust the pH to 5.5, 450W ultrasonic treatment for 20min, place in Preheat in a water bath at 55°C for 15 minutes, then add α-amylase and glucoamylase according to 6.0% and 1.6% of the mass of corn starch, and after 26 hours of enzymolysis reaction in a constant temperature water bath, inactivate the enzyme to terminate the reaction Vacuum suction filtration of the starch solution, washing with deionized water, suction filtration, and freeze-drying at -30°C for 25 hours to obtain porous starch;

[0029] 2) According to the mass-volume ratio of 1:120g / mL, add the weighed chitosan into 0.096M hydrochloric acid solution, and fully stir in an oil bath a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com