Trench type MPS diode cellular structure based on SiC substrate

A diode and trench technology, applied in the cell structure field of trench MPS diodes based on SiC substrates, can solve the problems of unstable device performance, uneven current distribution, and reduced Schottky barrier, and achieve elimination The effect of snapback effect, reduction of surface electric field strength, and enhancement of working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

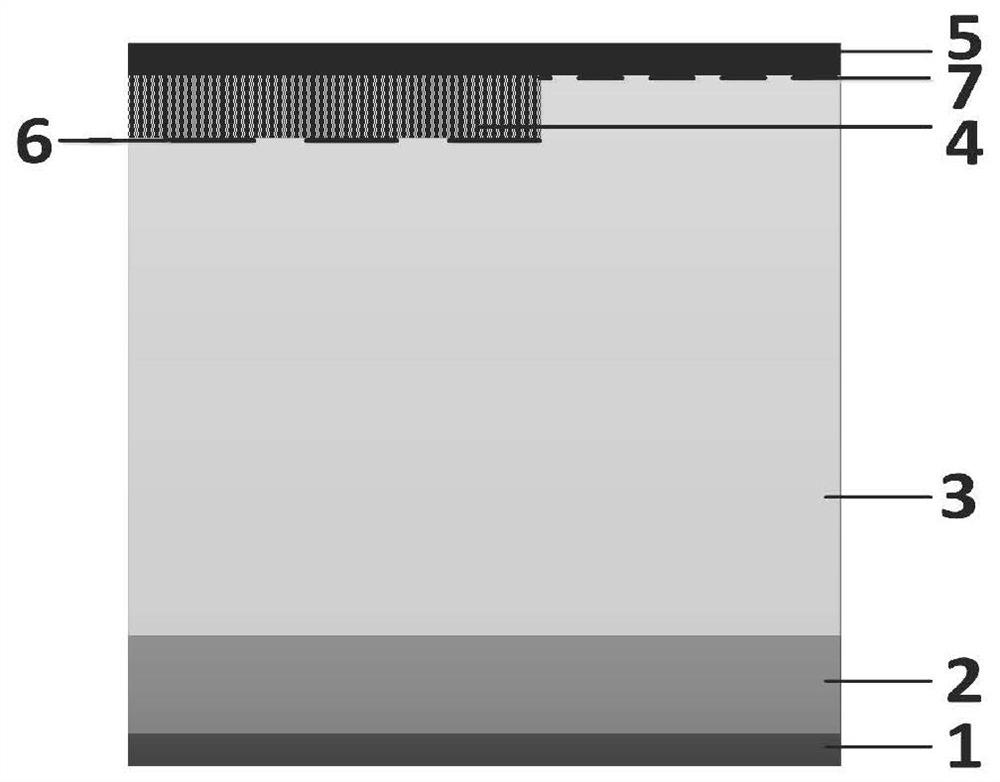

[0043] Such as figure 2 As shown, the present invention relates to a trench type MPS diode cell structure based on a SiC substrate, the device includes a cathode metal Al contact region 1, an N+ high-concentration substrate layer 2, an N- low-concentration epitaxial layer 3, and a P+ emitter region 4 , Trench HfO 2 Dielectric region 5 , anode metal Ni contact region 6 , P+N-junction contact surface 7 and anode metal NiN-Schottky junction contact surface 8 .

[0044] The cathode metal Al contact region 1 is located on the lower surface of the N+ high-concentration substrate layer 2 , and the cathode metal Al contact region 1 has a width of 5 μm and a thickness of 0.1 μm.

[0045] The N+ high-concentration substrate layer 2 is respectively located on the lower surface of the N- low-concentration epitaxial layer 3 and the upper surface of the cathode metal Al contact region 1; the N+ high-concentration substrate layer 2 is doped silicon carbide with a width of 5 μm and a thickn...

Embodiment 2

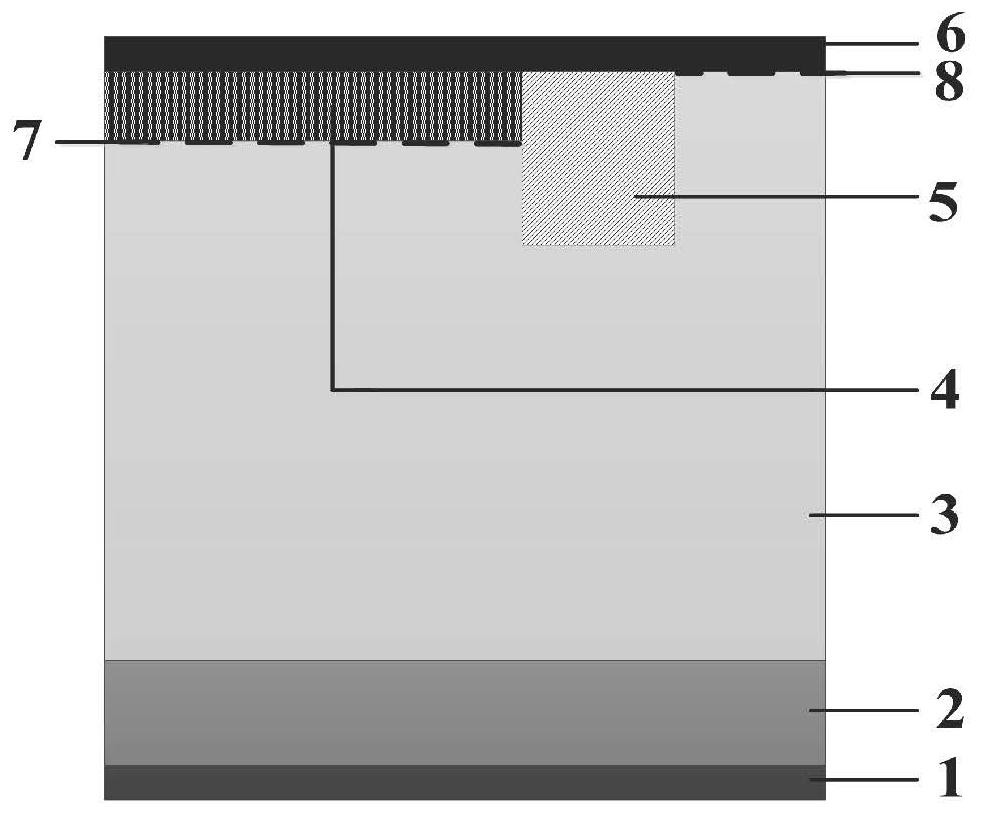

[0053] Such as image 3 As shown, the present invention relates to a trench type MPS diode cell structure based on a SiC substrate, the device includes a cathode metal Al contact region 1, an N+ high-concentration substrate layer 2, an N- low-concentration epitaxial layer 3, and a P+ emitter region 4 , P-type guard ring 5, trench SiO 2 Dielectric region 6 , anode metal Ni contact region 7 , P+N-junction contact surface 8 and anode metal NiN-Schottky junction contact surface 9 .

[0054] The cathode metal Al contact region 1 is located on the lower surface of the N+ high-concentration substrate layer 2 , and the cathode metal Al contact region 1 has a width of 5 μm and a thickness of 0.1 μm.

[0055] The N+ high-concentration substrate layer 2 is respectively located on the lower surface of the N- low-concentration epitaxial layer 3 and the upper surface of the cathode metal Al contact region 1; the N+ high-concentration substrate layer 2 is doped silicon carbide with a width ...

Embodiment 3

[0064] Such as Figure 4 As shown, the present invention relates to a trench type MPS diode cell structure based on a SiC substrate, the device includes a cathode metal Al contact region 1, an N+ high-concentration substrate layer 2, an N- low-concentration epitaxial layer 3, and a P+ emitter region 4 , P-type guard ring 5, SiO 2 Isolation ring 6 , heavily doped N+ polysilicon 7 , anode metal Ni contact region 8 , P+N-junction contact surface 9 and anode metal NiN-Schottky junction contact surface 10 .

[0065] The cathode metal Al contact region 1 is located on the lower surface of the N+ high-concentration substrate layer 2 , and the cathode metal Al contact region 1 has a width of 5 μm and a thickness of 0.1 μm.

[0066]The N+ high-concentration substrate layer 2 is respectively located on the lower surface of the N- low-concentration epitaxial layer 3 and the upper surface of the cathode metal Al contact region 1; the N+ high-concentration substrate layer 2 is doped silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com