Method for simultaneously detecting 33 plastic additives in food contact material

A technology for food contact materials and additives, applied in the field of analysis and detection, can solve the problems of low detection efficiency and long detection time, and achieve the effects of high detection efficiency, short detection time and good market application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

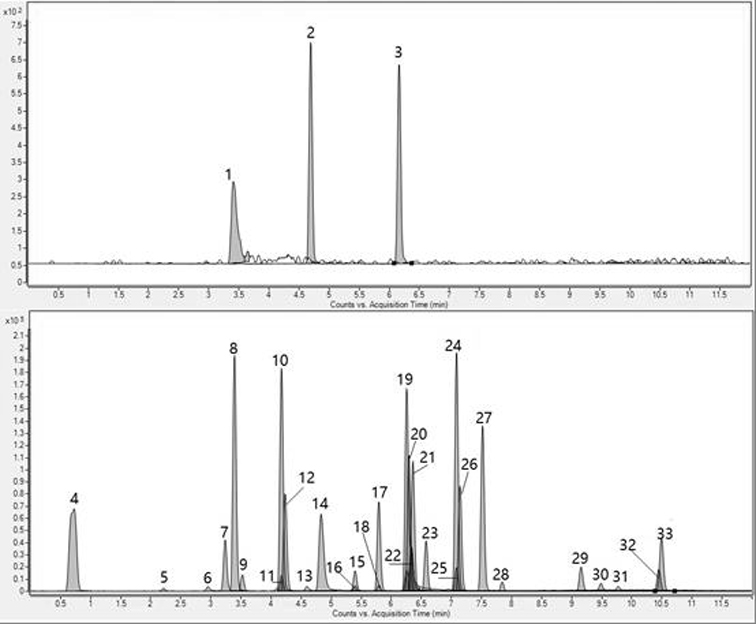

[0034] A series of standard solutions with a concentration of 1ng / mL~1000ng / mL were prepared for 33 kinds of plastic additive standard products with methanol as a solvent, and they were detected by liquid chromatography-tandem mass spectrometry to establish a standard curve by the external standard method.

[0035] Chromatographic conditions:

[0036] Column: C 18 (1.8µm, 2.1×50mm);

[0037] Mobile phase: A: aqueous solution (5mM ammonium acetate); B: methanol; gradient program: 0~3.0 min, 15%~60% B; 3.0~5.0min, 60%~75% B; 5.0~6.0 min, 75% ~85 % B; 6.0~8.0 min, 85%~92% B; 8.0~10.0min, 92%~95% B; 10.0~12.0min, 95%~95% B;

[0038] Injection volume: 2 µL; flow rate: 0.35 mL / min; column temperature: 30 o c.

[0039] Mass Spectrometry Conditions: Ionization Mode: Electrospray Dual Spray Ion Source, Positive Ion Mode + Negative Ion Mode (Dual AJSESI+, ESI-); Mass Spectrometry Scanning Mode: Multiple Reaction Monitoring-MRM Mode; Nebulizer Pressure: 35 psi; Gas Temperature: 250...

Embodiment 2

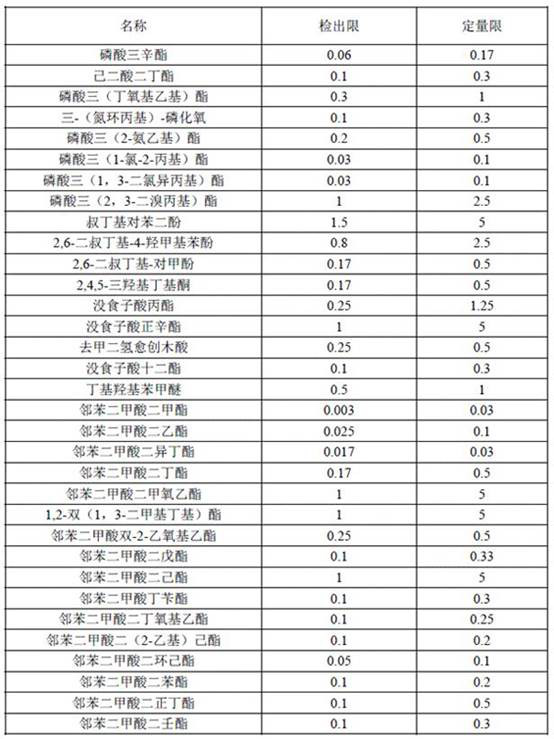

[0045] Use methanol as the low-concentration standard solution of solvent preparation 33 kinds of plastic additive standard items, detect with the liquid chromatography-tandem mass spectrometry method of the present invention, determine the detection limit according to the standard that signal-to-noise ratio S / N is greater than 3, signal-to-noise ratio S / N greater than 10 determines the limit of quantitation. Chromatographic conditions: Chromatographic column: C 18 (1.8µm, 2.1×50mm) ; Mobile phase: A: aqueous solution (5mM ammonium acetate); B: methanol; gradient program: 0~3.0 min, 15%~60% B; 3.0~5.0 min, 60%~75% B; 5.0~6.0 min, 75%~85 %B; 6.0~8.0 min, 85%~92%, B; 8.0~10.0 min, 92%~95% B; 10.0~12.0min, 95%~95% B ;Injection volume: 2 µL; Flow rate: 0.35 mL / min; Column temperature: 30 o c. Mass Spectrometry Conditions: Ionization Mode: Electrospray Dual Spray Ion Source, Positive Ion Mode + Negative Ion Mode (Dual AJS ESI+, ESI-); Mass Spectrometry Scanning Mode: Multiple ...

Embodiment 3

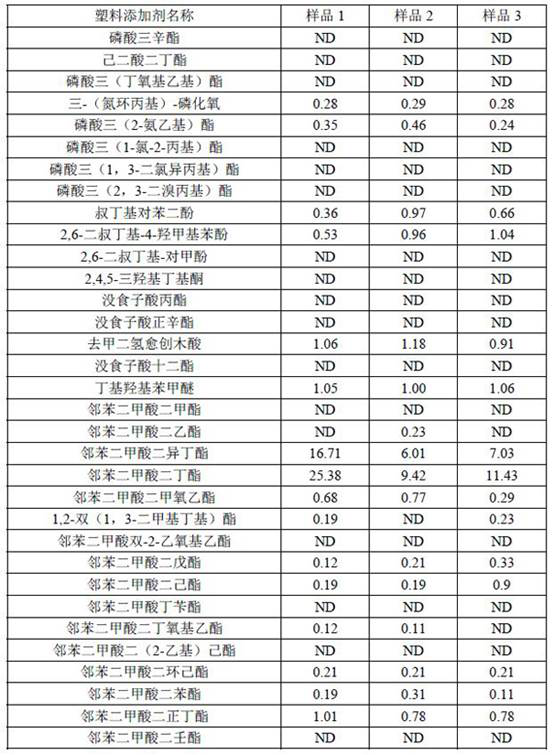

[0049] Take a blank PE plastic film as a sample, cut it to 5mm×5mm, weigh 0.5g as a sample, accurate to 0.1mg, put it in a stoppered test tube, add standard solutions of 33 kinds of plastic additives, the concentration is 10ng / g 10mL of methanol, sealed, after infiltrating the sample components, put it into an ultrasonic cleaner, and extract it ultrasonically for 40min under the condition of 40°C±3°C. After the stoppered test tube was cooled to room temperature, the extract was completely transferred to a volumetric flask, and the stoppered test tube was washed with suitable methanol for the second time, the combined extract was concentrated to 1 mL by nitrogen purging on a nitrogen blowing instrument, and then washed with methanol. Dilute to 5.00mL, pass through a 0.22µm filter membrane, and the filtrate is detected by liquid chromatography-tandem mass spectrometry.

[0050] The detection method is:

[0051] Chromatographic conditions: Chromatographic column: C 18 (1.8µm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com