Cold-formed steel tough combined bridge deck with box-shaped ribs

A technology of cold-formed steel and composite bridges, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as increasing bridge structure repair and maintenance costs, affecting the corrosion resistance and durability of bridge decks, and affecting structural fatigue performance. Achieve the effects of improving stability and lateral torsional force performance, blocking steel from the external environment, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

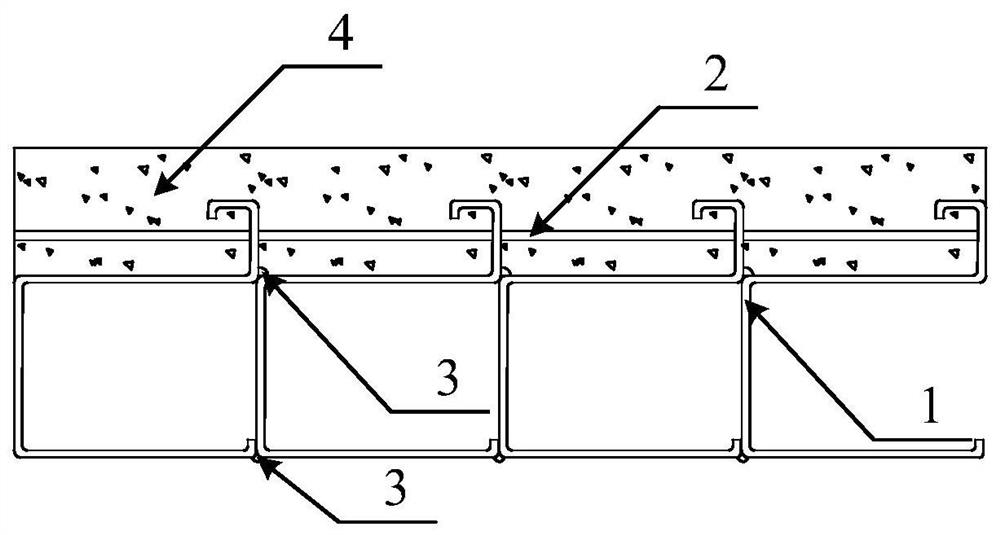

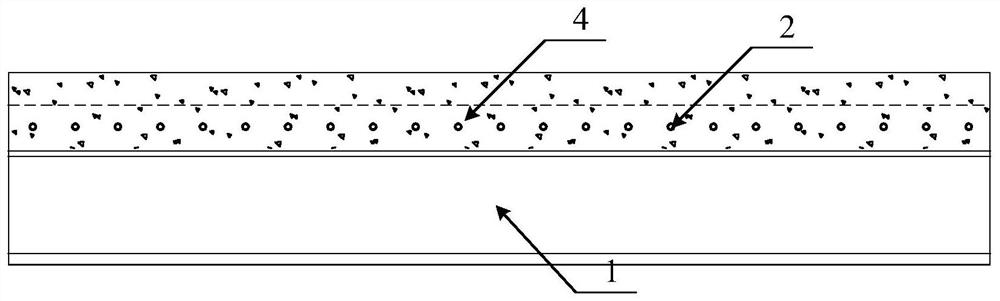

[0037] Such as figure 1 and figure 2 As shown, a cold-formed steel ductile composite bridge deck with box ribs includes the following components: cold-formed rolled-edge steel 1, transverse steel bars 2, and ultra-high toughness concrete 4.

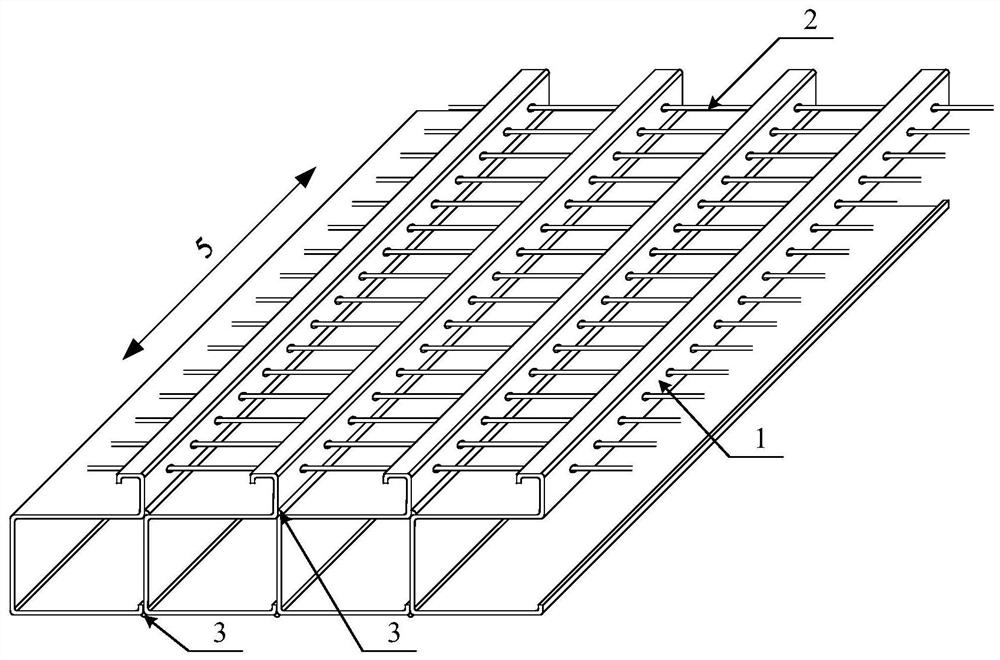

[0038] Such as image 3 As shown, the cold-formed hemming section steels 1 are continuously placed side by side along the transverse direction of the bridge deck, and adjacent section steels 1 are welded by two fillet welds 3 to form the steel skeleton of the bridge deck. 5 is the longitudinal direction of the bridge deck.

[0039] Such as Figure 4 As shown, the lower side flange of the cold-formed hemming steel 1 is longer, forming a box-shaped rib structure to strengthen the outside of the board; the upper side flange of the cold-formed hemming steel 1 is shorter and has a row of circles on it. Holes, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com