Self-adhesive flame-retardant epoxy resin and preparation method thereof

A technology of epoxy resin and phenolic epoxy resin, which is applied in the field of composite materials, can solve the problems of difficulty in meeting the requirements of the overall weight of the component, the reduction of the toughness and viscosity of the epoxy resin, and the decline of its own mechanical properties, and achieves moderate viscosity, toughness and The effect of improved adhesion and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

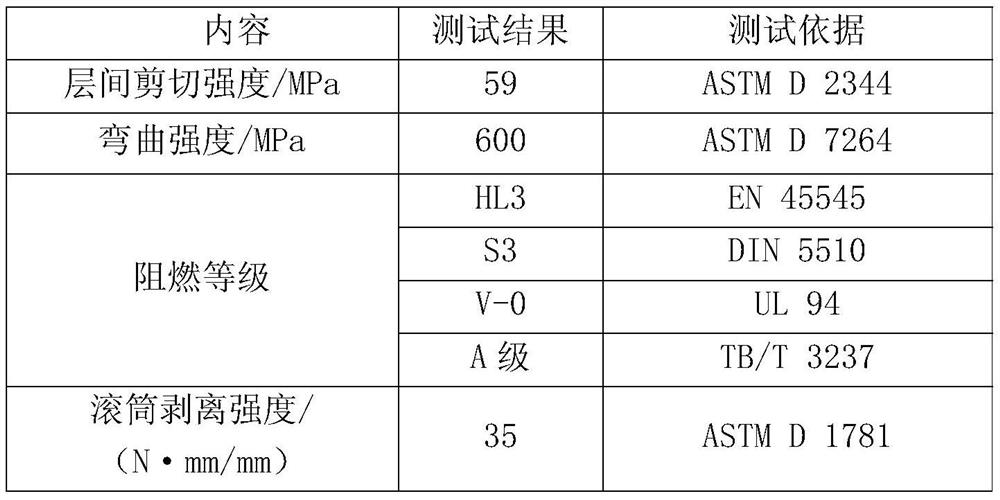

Embodiment 1

[0029] A preparation method of self-adhesive flame-retardant epoxy resin, by weight, comprising the following steps:

[0030] (1) 50 parts of biphenyl type epoxy resin BPNE3501, 30 parts of o-cresol type phenolic resin JF45, 20 parts of bisphenol A epoxy resin E51, 10 parts of thermoplastic modified polyether ketone PEKC and 1 part The dispersant HYPER C100 was added to the reactor and heated and stirred. When the temperature rose to 110°C, the system was completely dissolved and evenly dissolved. After that, the heating and stirring was stopped to obtain a prepolymer, which was cooled for later use;

[0031] (2) Transfer the above prepolymer into a vacuum kneader for pre-stirring and mixing, and add 20 parts of melamine cyanurate (MCA) and 20 parts of hexaphenoxycyclotriphosphazene (HPCTP), and mix for 15 minutes , add 4 parts of dicyandiamide curing agent and 4 parts of organic urea accelerator UR300 in proportion, and continue stirring and mixing for 150 minutes to obtain a...

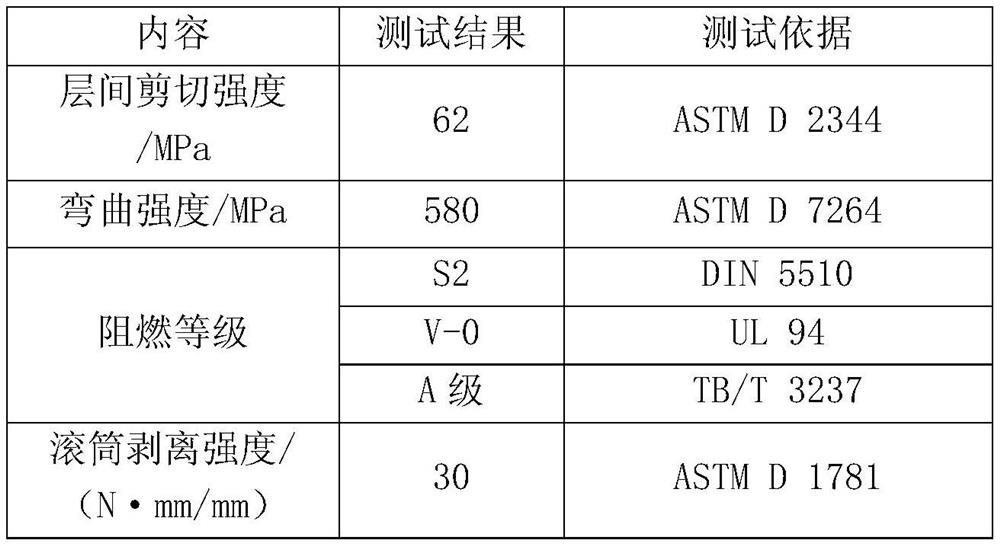

Embodiment 2

[0038] A preparation method of self-adhesive flame-retardant epoxy resin, by weight, comprising the following steps:

[0039] (1) 40 parts of CTBN modified epoxy resin HQ-3600, 40 parts of phenol formaldehyde epoxy resin SNE-625, 20 parts of triglycidyl isocyanurate (TGIC), 8 parts of thermoplastic polyethersulfone (PES), Add 2 parts of fumed silica as a dispersant, heat and stir in the reaction kettle, the temperature rises to 170°C and the system is completely dissolved, then stop heating and stirring to obtain a prepolymer, and cool it for later use.

[0040] (2) Transfer the above prepolymer into a vacuum kneader for pre-stirring and mixing, add 10 parts of melamine cyanurate (MCA), 20 parts of ammonium polyphosphate (APP), and 5 parts of magnesium hydroxide, and stir and mix After 10 minutes, add 30 parts of 4,4-diaminodiphenylmethane DDM and 5 parts of 2-ethyl-4-methylimidazole in proportion, and continue stirring and mixing for 10 minutes to obtain a predispersion, whic...

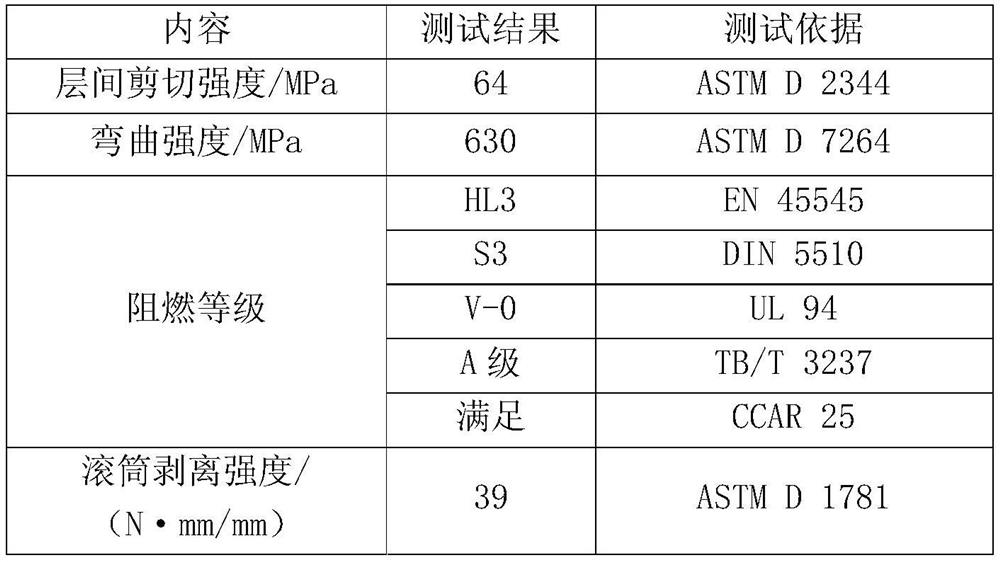

Embodiment 3

[0047] A preparation method of self-adhesive flame-retardant epoxy resin, by weight, comprising the following steps:

[0048] (1) 40 parts of biphenyl type epoxy resin YLE-4000S, 30 parts of CTBN modified epoxy resin HQ-3600, 30 parts of o-cresol type phenolic resin JF45, 3 parts of thermoplastic polyether ketone ketone PEKK, 1 part The dispersant HYPER C100 and 1 part of fumed silica were added, heated and stirred in a planetary disperser, and the temperature rose to 160°C. After the system was completely dissolved and uniform, the heating and stirring was stopped to obtain a prepolymer, which was cooled for later use.

[0049] (2) Transfer the above prepolymer into a vacuum kneader for pre-stirring and mixing, add 10 parts of melamine cyanurate (MCA), 20 parts of ammonium polyphosphate (APP), 10 parts of hexaphenoxycyclotriphosphorus Nitrile (HPCTP), after stirring for 10 minutes, add 5 parts of dicyandiamide and 3 parts of organic urea accelerator UR300 in proportion, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com