Preparation method of graphene/polyvinyl chloride composite material

A technology of composite materials and polyvinyl chloride, which is applied in the field of preparation of graphene/polyvinyl chloride composite materials, can solve the problems of large consumption, potential safety hazards, and non-renewability, and achieve the effects of solving cracking, low cost, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

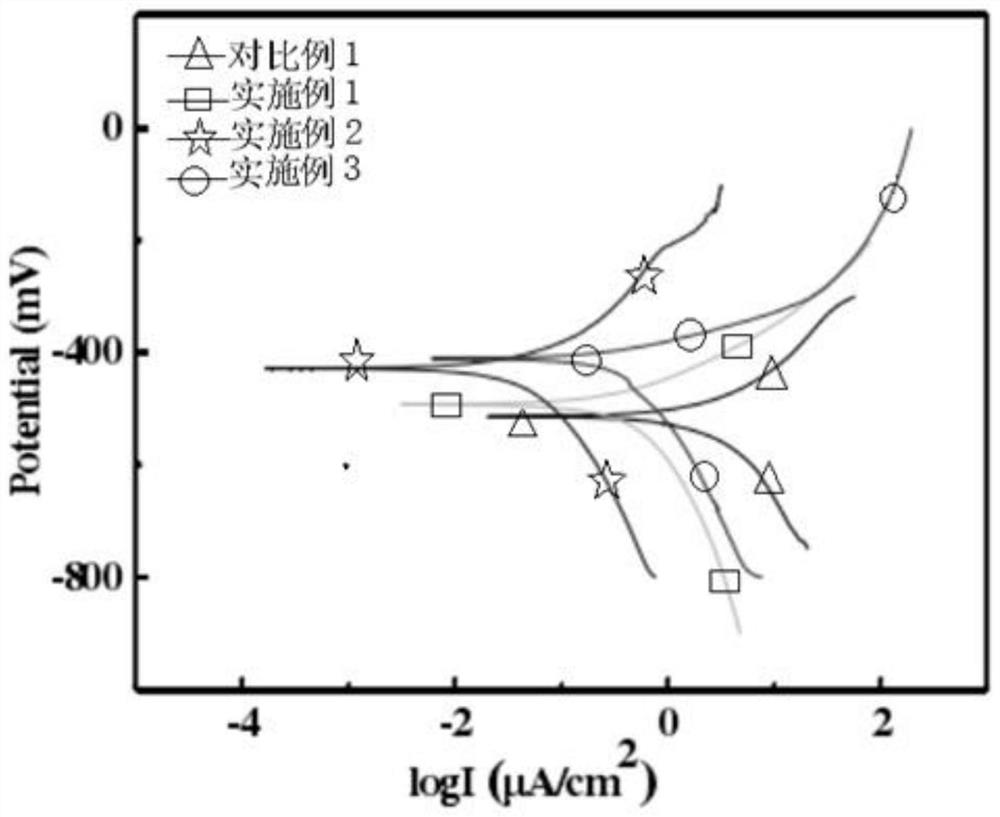

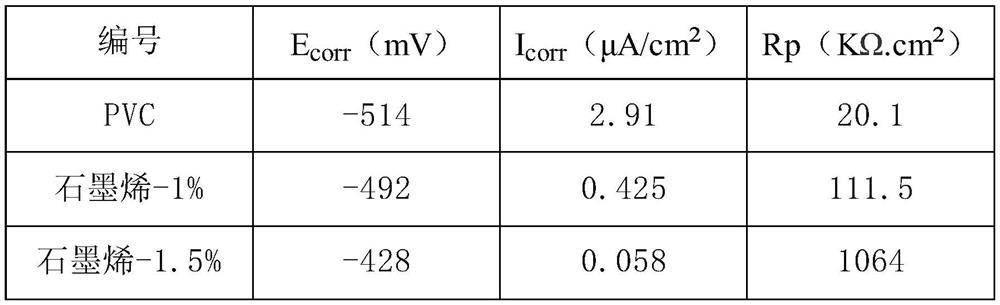

Embodiment 1

[0036] A kind of preparation method of graphene / polyvinyl chloride composite material, comprises the steps:

[0037] 1. Preparation of modified graphene:

[0038] (1) Add 1.0 g of sodium nitrate (NaNO 3 ) and 46.0mL of sulfurous acid (H 2 SO 3 ) and mix well, then add 2.0g of graphene and stir evenly to obtain mixed solution A;

[0039] (2) Add 6.0 g of potassium permanganate (KMnO 4 ) and magnetically stirred for 2 hours. After the reaction, 92.0 mL of deionized water was added and rapidly heated to 98° C., kept at this temperature for 15 minutes, and then 280.0 mL (large amount) of deionized water was added to terminate the reaction;

[0040] (3) After the reaction is terminated, add 5.0 mL of hydrogen peroxide (H 2 o 2 ) and stirred evenly with a glass rod, the reaction system changed from brown-black to bright yellow, then filtered while hot, and then washed the filter residue with hydrochloric acid, then washed with deionized water until neutral, and then dried in a...

Embodiment 2

[0051] A kind of preparation method of graphene / polyvinyl chloride composite material, comprises the steps:

[0052] 1. Preparation of modified graphene:

[0053] (1) Add 1.0 g of sodium nitrate (NaNO 3 ) and 40.0mL of sulfurous acid (H 2 SO 3 ) and mix well, then add 3.0g of graphene and stir evenly to obtain mixed solution A;

[0054] (2) Add 7.5 g of potassium permanganate (KMnO 4 ) and magnetically stirred for 4 hours. After the reaction, 100.0 mL of deionized water was added and rapidly heated to 90° C., kept at this temperature for 20 minutes, and then 300.0 mL (a large amount) of deionized water was added to terminate the reaction;

[0055] (3) After the reaction is terminated, add 5.0 mL of hydrogen peroxide (H 2 o 2 ) and stirred evenly with a glass rod, the reaction system changed from brown-black to bright yellow, then filtered while hot, and then washed the filter residue with hydrochloric acid, then washed with deionized water until neutral, and then dried i...

Embodiment 3

[0066] A kind of preparation method of graphene / polyvinyl chloride composite material, comprises the steps:

[0067] 1. Preparation of modified graphene:

[0068] (1) Add 1.0 g of sodium nitrate (NaNO 3 ) and 50.0mL of sulfurous acid (H 2 SO 3 ) and mix evenly, then add 1.0g of graphene and stir evenly to obtain mixed solution A;

[0069] (2) Add 4.0 g of potassium permanganate (KMnO 4 ) and magnetically stirred for 5 hours. After the reaction, 50.0 mL of deionized water was added and rapidly heated to 95° C., kept at this temperature for 10 minutes, and then 250.0 mL (large amount) of deionized water was added to terminate the reaction;

[0070] (3) After the reaction is terminated, add 6.0 mL of hydrogen peroxide (H 2 o 2 ) and stirred evenly with a glass rod, the reaction system changed from brown-black to bright yellow, then filtered while hot, and then washed the filter residue with hydrochloric acid, then washed with deionized water until neutral, and then dried in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com