Tile forming machine and tile manufacturing method

A production method and technology of a forming machine, which are applied in the field of tile forming machines and tile production, can solve problems such as tile defects and nodes that cannot be formed, and achieve the effects of fewer installation accessories, clear tile outlines, and guaranteed integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

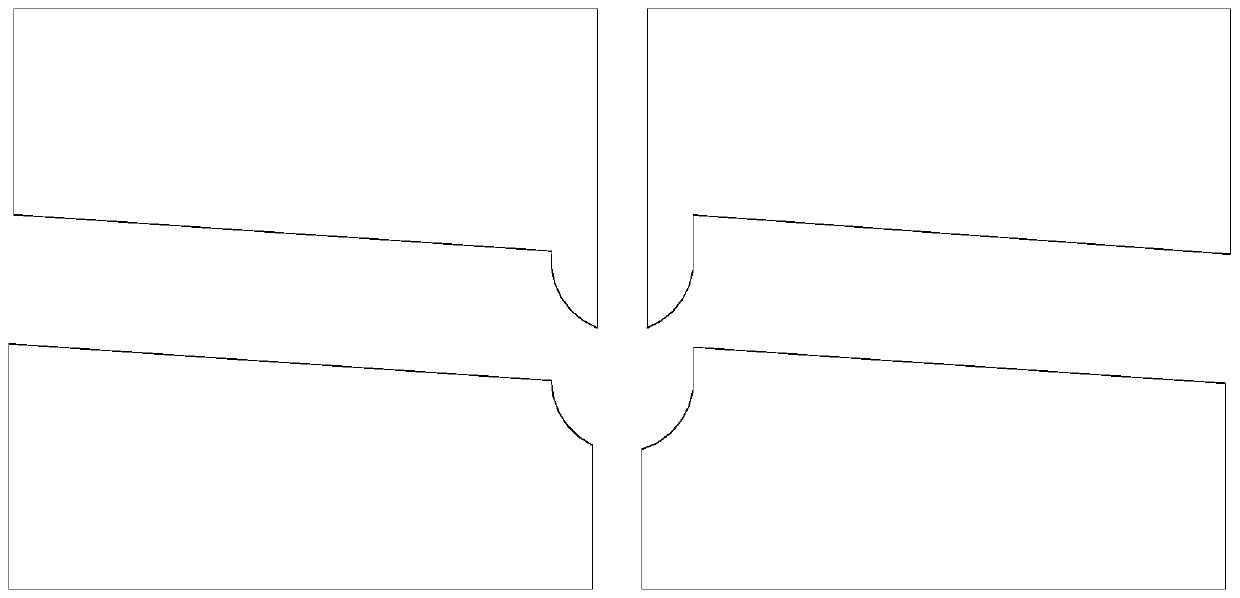

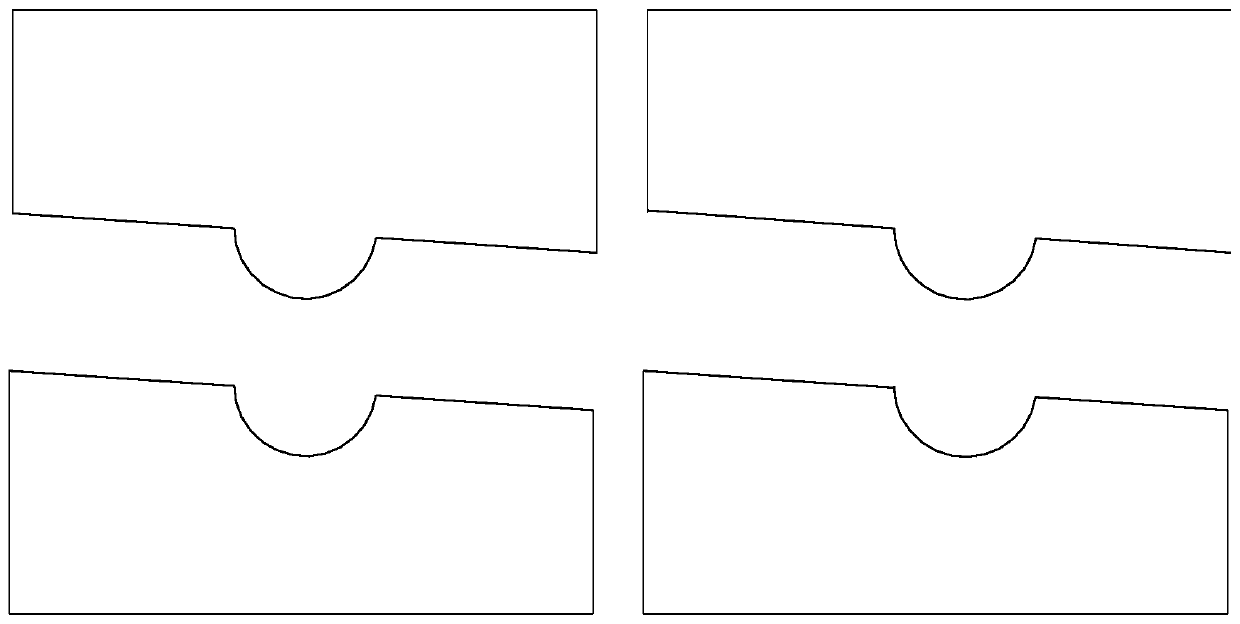

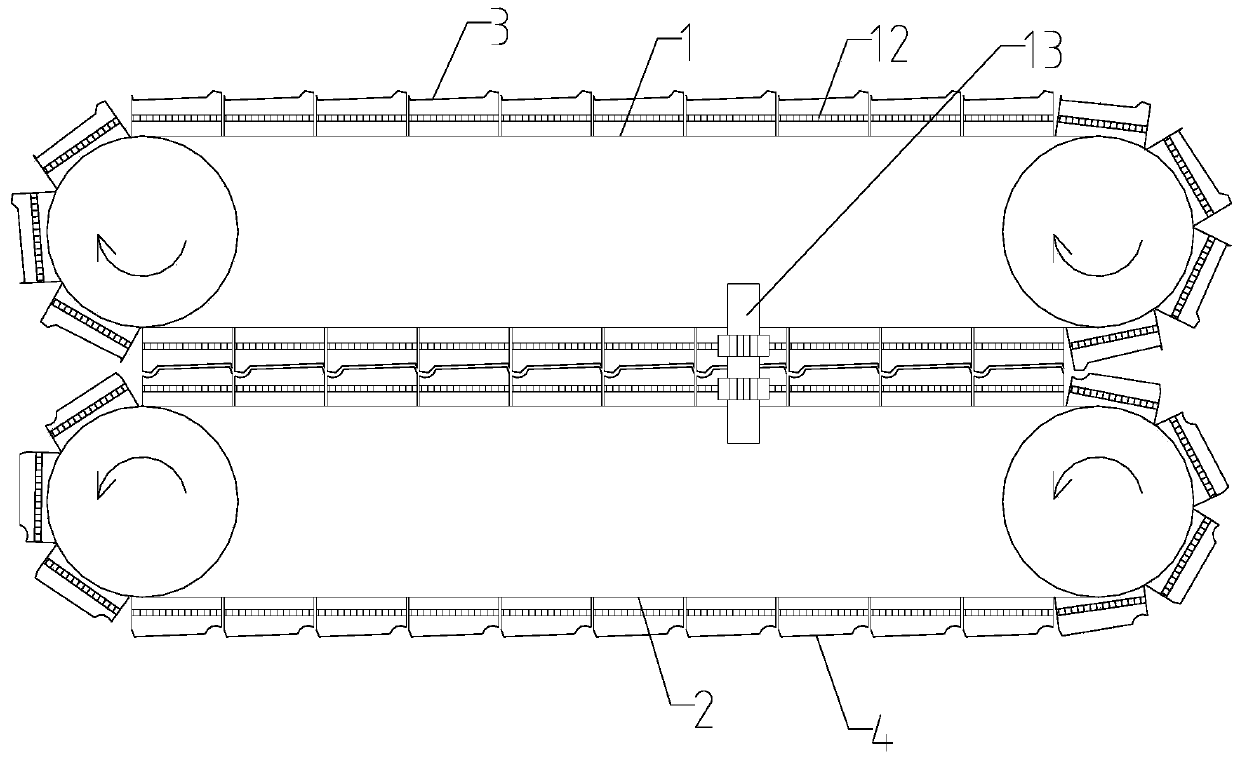

[0036] Such as image 3 and Figure 4 As shown, a tile forming machine includes an upper crawler 1 and a lower crawler 2 arranged oppositely, and a power device for driving the upper crawler 1 and the lower crawler 2 to rotate. The upper crawler 1 is arranged with several upper molds 3, and the lower crawler 2. A number of lower molds 4 are arranged on the upper side. The rotation directions of the upper crawler belt 1 and the lower crawler belt 2 are opposite so that the upper mold 3 and the lower mold 4 move synchronously in the same direction after being pressed together. The upper mold 3 and the lower mold 4 is the tile raw material to be pressed, there is the same gap 7 between adjacent upper molds 3 and adjacent lower molds 4, and an arc-shaped convex groove 5 with a radius of R1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com