System for CD glow plasma CVD zin oxide film and preparing process

A technology of chemical vapor deposition and zinc oxide thin film, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of unstable quality and difficulty in reproducing the film, and achieve high growth rate and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

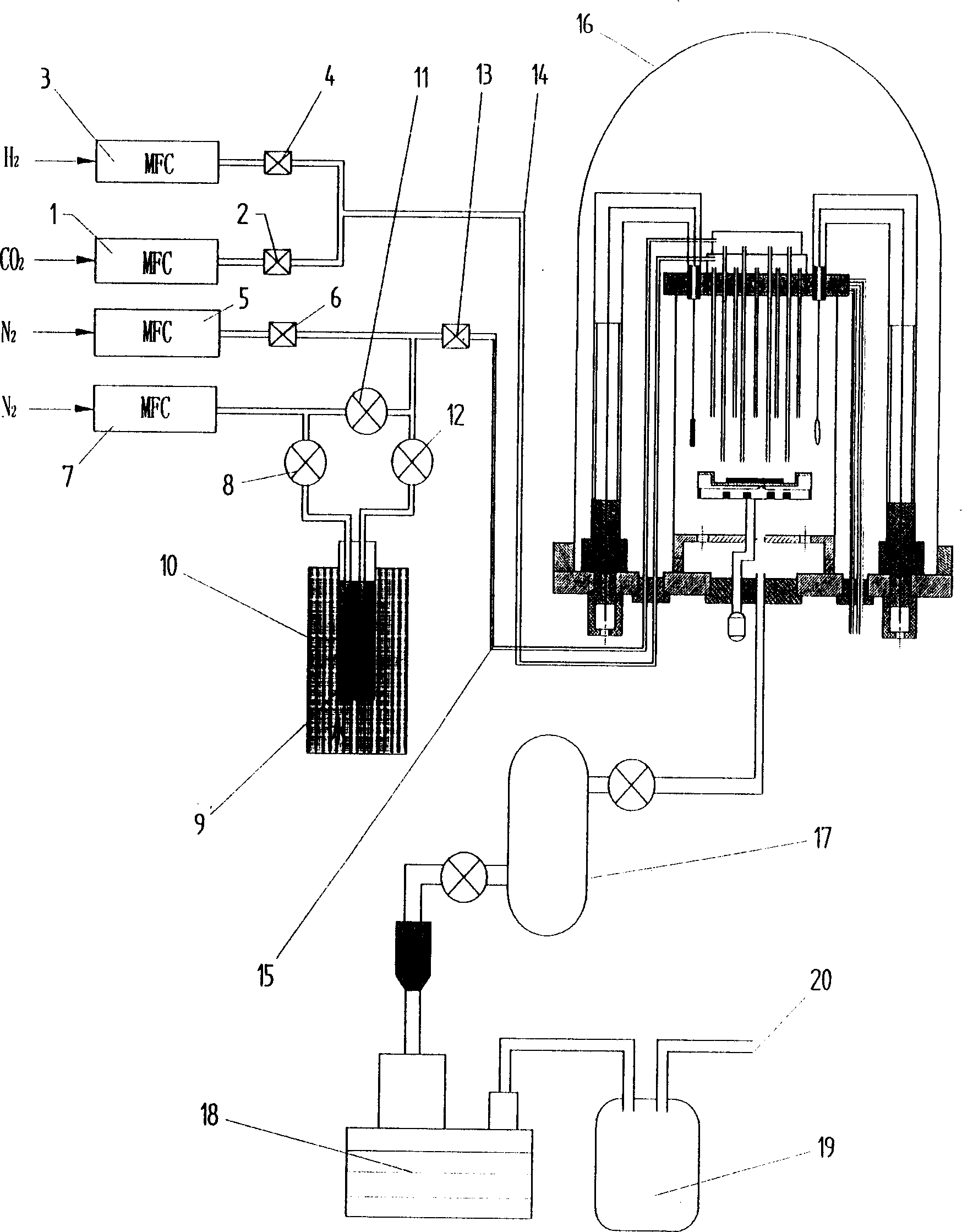

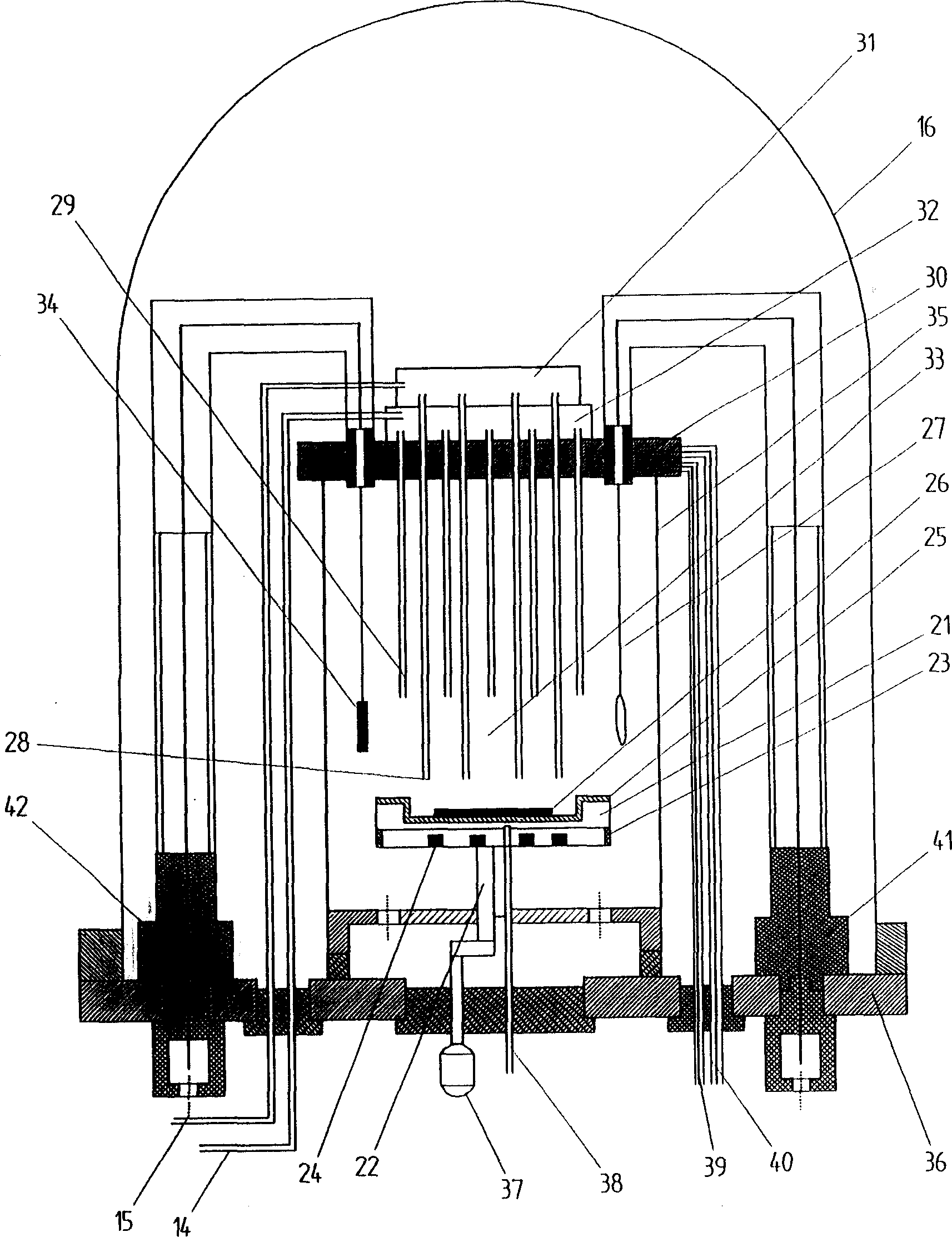

[0018]The present invention comprises vacuum reaction hood 16, upper air intake pipe 15, lower air intake pipe 14, quartz reaction chamber 35, insulating seat 36 and particle filter 17, air pump 18, combustion bottle 19 and exhaust port 20 installed under vacuum reaction hood 16 , carbon dioxide passes through gas flowmeter 1, electromagnetic valve 2, hydrogen gas meets carbon dioxide after passing through gas flowmeter 3, electromagnetic valve 4, enters the lower intake pipe 14, and the steel cylinder 9 with diethylzinc or dimethylzinc is placed in the In the temperature control box 10 with water, nitrogen gas with a small flow rate flows through the steel cylinder 9 through the gas flow meter 7 and the manual valve 8, and bubbles are blown up, and diethyl zinc or dimethyl zinc vapor is taken out through the manual valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com