Method for rapidly dissolving Laves phase in deformed high-temperature alloy ingot by pulse current

A technology of deforming superalloys and pulse currents, applied in the field of deforming superalloys, can solve the problems of complex process, high processing temperature and long processing time of homogenization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

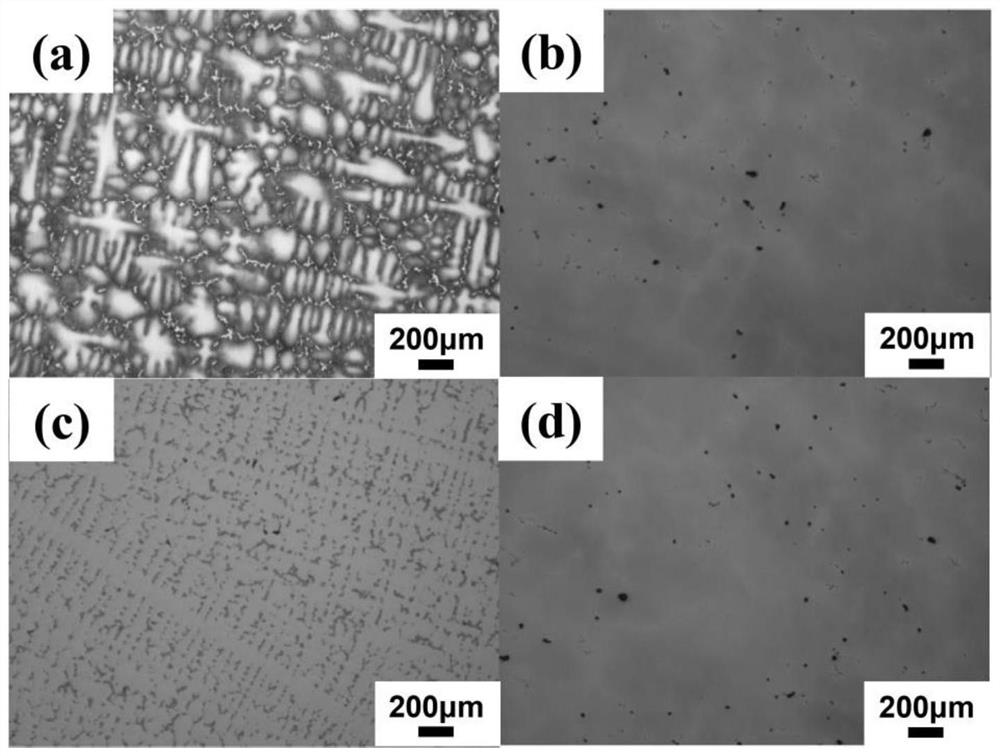

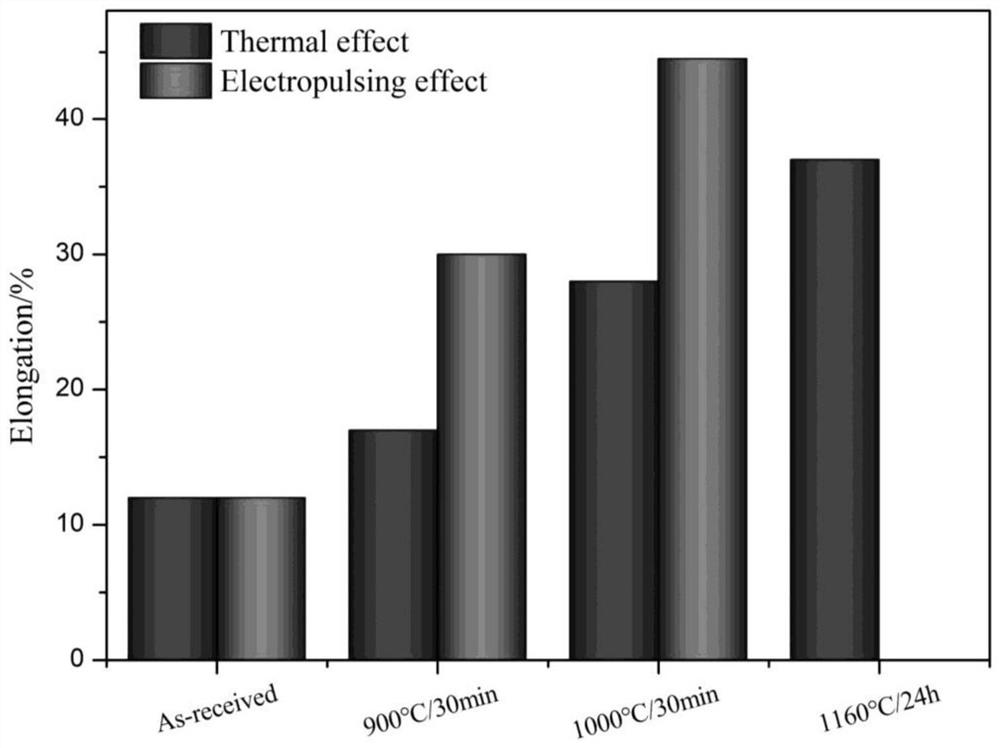

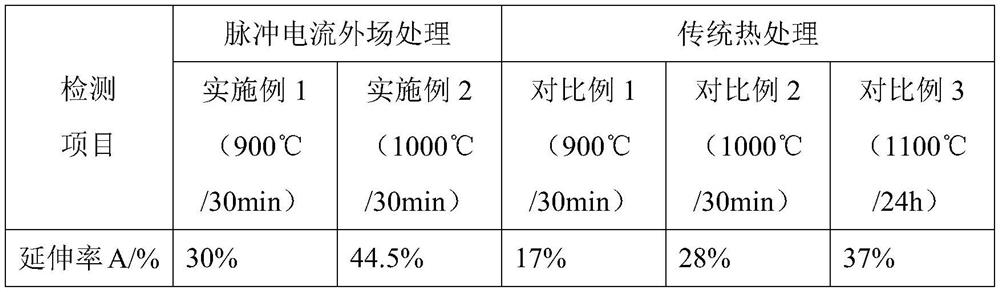

[0037] A method for rapidly dissolving the Laves phase in a deformed superalloy ingot by pulse current, comprising the following steps: performing pulse current external field treatment on the deformed superalloy ingot, and the specific operation steps are as follows:

[0038] S1. The surface of the GH4169D new nickel-based superalloy ingot is polished with 180 mesh, 600 mesh, 1000 mesh, 1500 mesh and 2000 mesh sandpaper in sequence until there are no visible defects to the naked eye, and then the GH4169D alloy ingot is passed through a pure copper wire and a pure copper fixture Connect to both ends of the pulse power supply;

[0039] S2. Set the pulse frequency to 30000Hz, set the current and voltage parameters so that the current density is 16.35A / mm 2 , continue pulse treatment at room temperature for 30min, then disconnect the power supply and air cool to room temperature. During the whole process, the surface temperature of the superalloy was 900 °C measured by the K-typ...

Embodiment 2

[0041] A method for quickly dissolving the Laves phase in a deformed superalloy ingot by a pulse current, using the GH4169D new nickel-based superalloy ingot with the same microstructure and mechanical properties as in Example 1, and proceeding according to the method in Example 1, the difference is that

[0042] The pulse current external field treatment is performed on the deformed superalloy ingot, and the specific operation steps are as follows:

[0043] S1. Grind the surface of the GH4169D new nickel-based superalloy ingot with 180 mesh, 600 mesh, 1000 mesh, 1500 mesh and 2000 mesh sandpaper in sequence until there are no visible defects to the naked eye, and then pass the GH4169D alloy rectangular ingot through a pure copper wire, pure copper The fixture is connected to both ends of the pulse power supply;

[0044] S2. Set the pulse frequency to 30000Hz, set the current and voltage parameters so that the current density is 18.5A / mm 2 , continue pulse treatment at room ...

Embodiment 3

[0046] A method for rapidly dissolving the Laves phase in a deformed superalloy ingot by a pulse current, selects the GH4169D new nickel-based superalloy ingot with the same microstructure and mechanical properties as in Example 2, and proceeds according to the method in Example 2, with the difference In step S2, the pulse current processing parameters are as follows:

[0047] Set the current and voltage parameters so that the current density is 1A / mm 2 , the pulse processing time is 10h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com