Self-hardening iron-based material for shear blade and preparation method of shear blade

A technology of iron-based materials and shearing blades, applied in shearing devices, knives for shearing devices, manufacturing tools, etc., can solve the problems of loss of wear resistance and fatigue resistance, and reduce manufacturing and processing costs , Reduce tempering process, improve impact toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

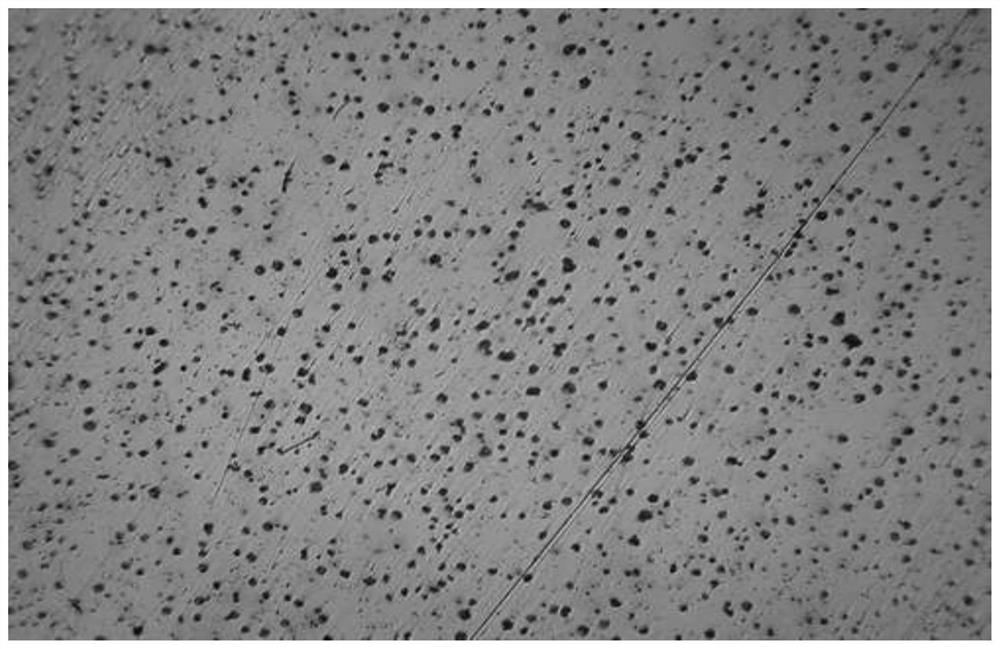

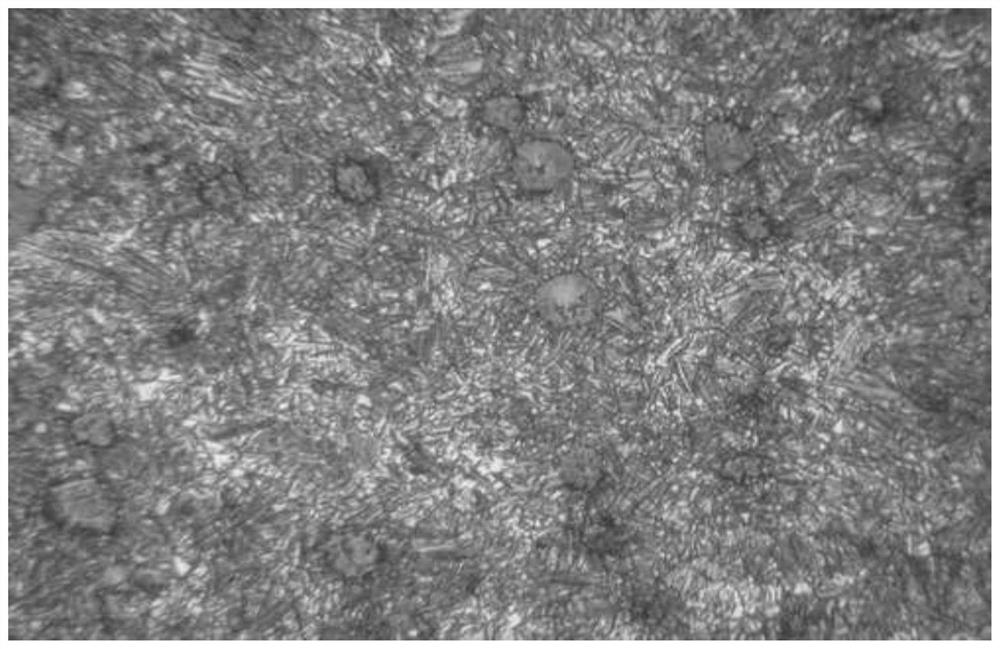

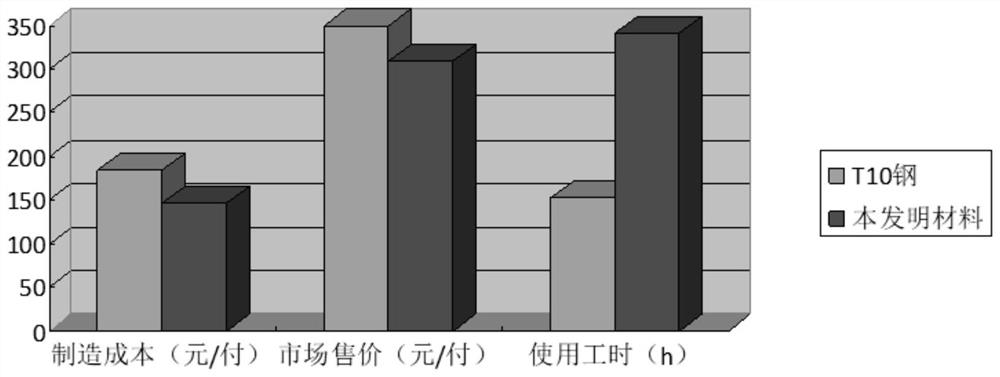

Image

Examples

Embodiment 1

[0041] The present invention adopts self-hardening iron-based material to prepare the method of shearing blade, specifically implements according to the following steps:

[0042] Step 1: Weigh the C content of 3.5%, Si content of 2.9%, Mn content of 0.3%, P content of no more than 0.06%, S content of no more than 0.02%, Re content of no more than 0.05%, and Mg content according to mass percentage. Not more than 0.04%, the balance being Fe;

[0043] Step 2, putting the raw materials weighed in step 1 into an induction furnace for melting at a temperature of 1500° C. for 35 minutes to obtain molten metal;

[0044] Step 3, transferring the molten metal obtained in step 2 into a transfer bag with a spheroidizer and an inoculant added in advance for spheroidization and inoculation, wherein the transfer bag is added in advance to obtain a qualified molten liquid;

[0045]Wherein, the nodulizer is 1.5% of the molten metal mass obtained in step 1, and the nodulizer is one of granular...

Embodiment 2

[0054] The present invention adopts self-hardening iron-based material to prepare the method of shearing blade, specifically implements according to the following steps:

[0055] Step 1: Weigh the C content of 3.0%, Si content of 2.6%, Mn content of 0.3%, P content of no more than 0.06%, S content of no more than 0.02%, Re content of no more than 0.05%, and Mg content according to mass percentage. Not more than 0.04%, the balance being Fe;

[0056] Step 2, putting the raw materials weighed in step 1 into an induction furnace for melting at a temperature of 1600° C. for 10 minutes to obtain molten metal;

[0057] Step 3, transferring the molten metal obtained in step 2 into a transfer bag with a spheroidizer and an inoculant added in advance for spheroidization and inoculation, wherein the transfer bag is added in advance to obtain a qualified molten liquid;

[0058] Wherein, the nodulizer is 1.3% of the molten metal quality obtained in step 1, and the nodulizer is one of gran...

Embodiment 3

[0064] The present invention adopts self-hardening iron-based material to prepare the method of shearing blade, specifically implements according to the following steps:

[0065] Step 1: Weigh the C content of 3.3%, Si content of 2.5%, Mn content of 0.1%, P content of no more than 0.06%, S content of no more than 0.02%, Re content of no more than 0.05%, and Mg content according to mass percentage. Not more than 0.04%, the balance being Fe;

[0066] Step 2, putting the raw materials weighed in step 1 into an induction furnace for melting at a temperature of 1400° C. for 60 minutes to obtain molten metal;

[0067] Step 3, transferring the molten metal obtained in step 2 into a transfer bag with a spheroidizer and an inoculant added in advance for spheroidization and inoculation, wherein the transfer bag is added in advance to obtain a qualified molten liquid;

[0068] Wherein, the nodulizer is 1.5% of the molten metal mass obtained in step 1, and the nodulizer is one of granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com