Oxidation ditch denitrification nitrogen removal control system

A control system and oxidation ditch technology, applied in water treatment parameter control, chemical instruments and methods, water treatment of special compounds, etc., can solve the concentration of organic pollutants is not high, the practicability is not strong, dissolved oxygen DO and organic matter concentration requirements Differences and other issues, to achieve precise control of carbon source dosage, strong pertinence and practicality, and convenient monitoring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples.

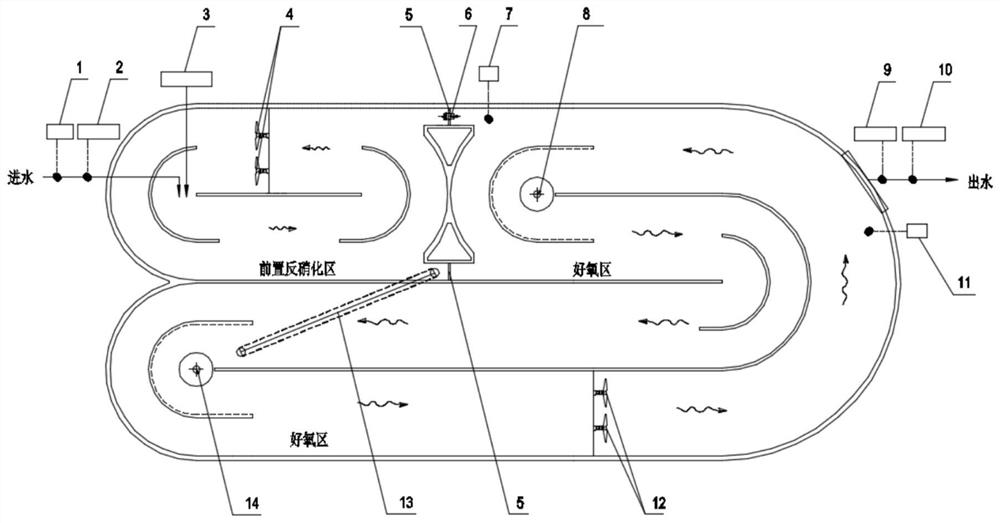

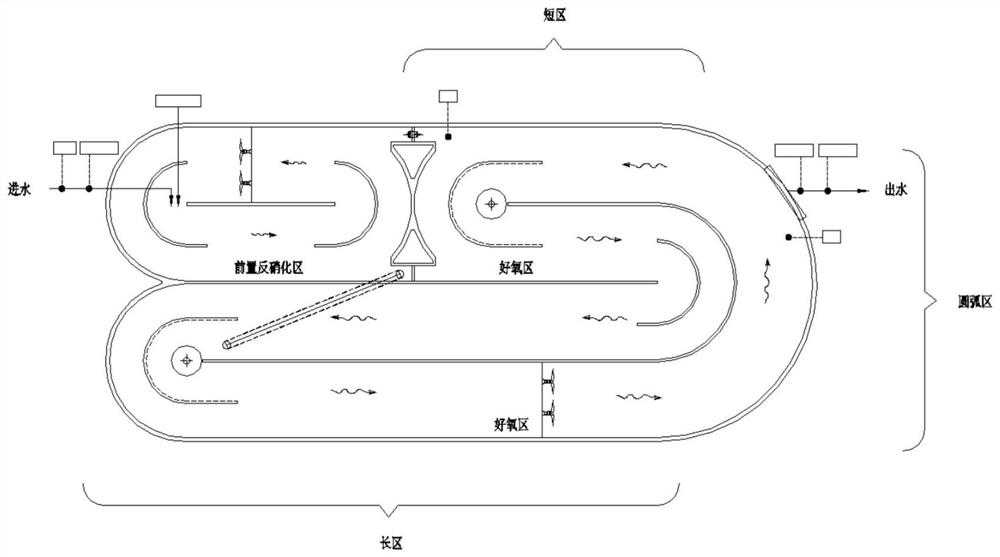

[0033] Such as figure 1 As shown, an oxidation ditch denitrification and denitrification control system is set up based on the Carrousel 2000 oxidation ditch. The oxidation ditch in the present invention includes two parts, the pre-denitrification zone and the aerobic zone, specifically the pre-denitrification zone. Where the denitrification area is connected to the aerobic area, a partition wall 5 is added to block the water flow, and the pre-denitrification area and the aerobic area are connected through the pre-buried diversion pipe 13 at the bottom of the pool; the water inlet pipeline leads to the pre-denitrification area, And the water outlet pipeline leads out from the outlet of the oxidation ditch located in the aerobic zone, the middle of the pre-denitrification zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com