Plant-derived PP master batch and preparation method thereof

A plant source and masterbatch technology, applied in the field of PP materials, can solve the problems of reduced content of active ingredients, limited use of plants, large molecular weight of PP, etc., and achieve the effects of large load capacity, good antibacterial, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

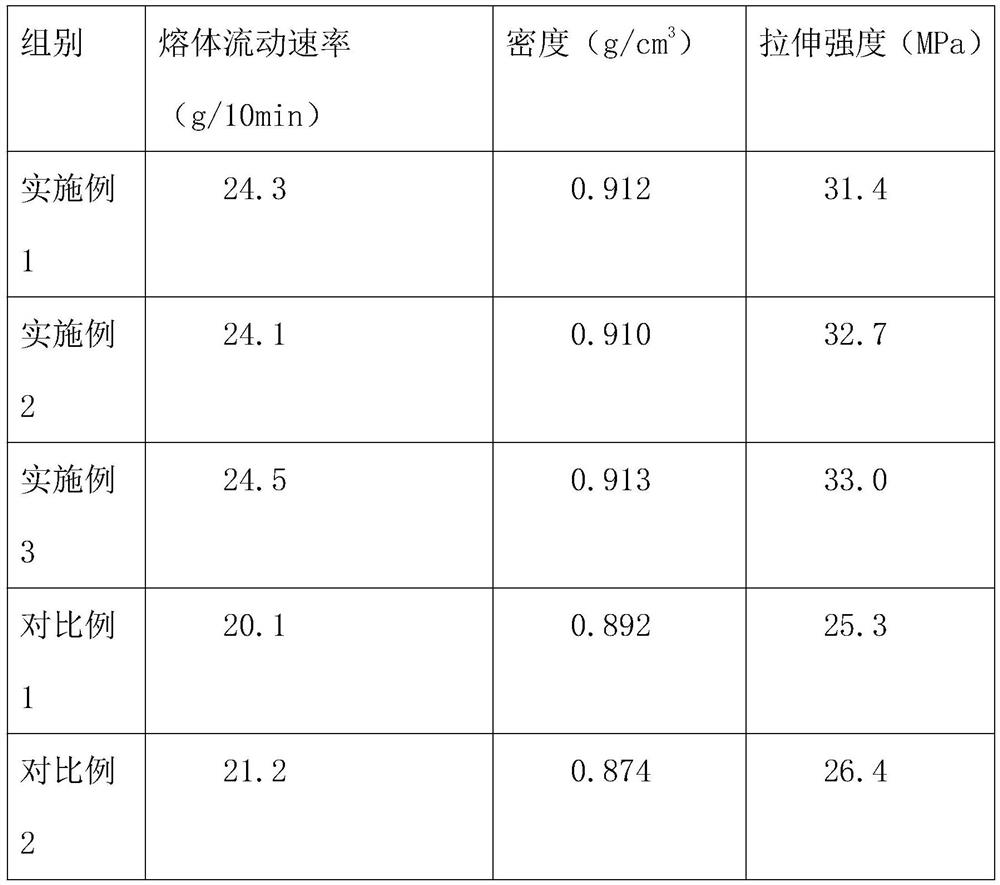

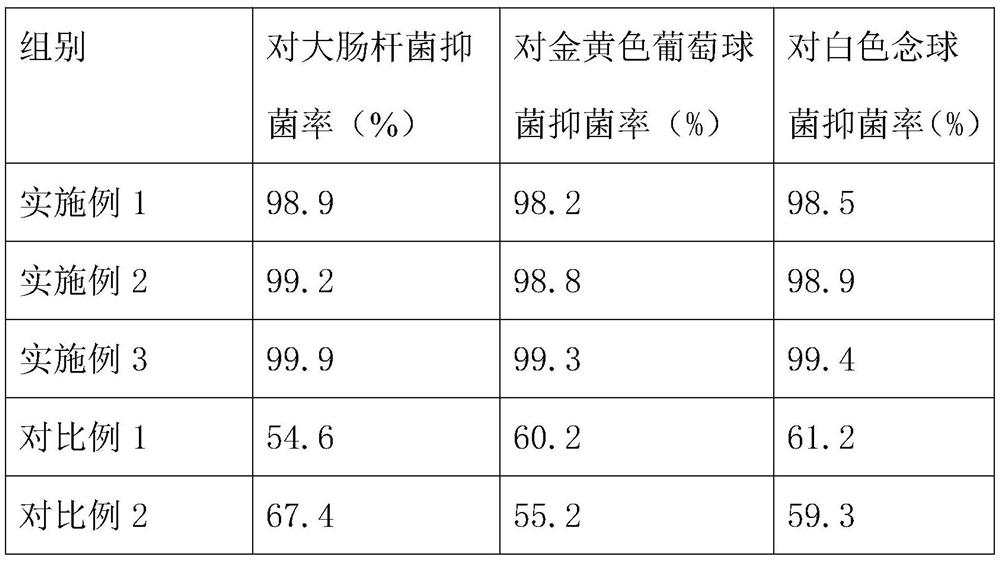

Examples

Embodiment 1

[0030] Embodiment 1 plant source PP masterbatch

[0031] S1. Treatment of montmorillonite: add 10 g of montmorillonite to 50 g of an aqueous solution containing 2.5 wt % silane coupling agent, react at 50° C. for 1 hour, and filter to obtain treated montmorillonite;

[0032]S2. Preparation of plant extract solution: Wash 5g Coptis Rhizoma, 10g Artemisia argyi, 1g Sophora flavescens, 2g Angelica dahurica, 1g Poria cocos, and 5g Atractylodes atractylodes, respectively, wash, dry, and crush to below 100 mesh, and add them according to the solid-liquid ratio of 1:5g / mL In deionized water, heated to boiling and extracted for 1 hour, filtered, and the filtrate was evaporated under reduced pressure to a relative density of 1.5 to obtain a plant extract solution;

[0033] S3. Preparation of composite nanomaterials: Add 2g of plant extract solution, 5g of montmorillonite treated in step S1, 1g of coupling agent, and 0.5g of surfactant into the shear disperser in sequence, at a speed of...

Embodiment 2

[0036] Embodiment 2 plant source PP masterbatch

[0037] S1, SiO 2 Microsphere treatment: 15g SiO 2 Add the microspheres to 100g of an aqueous solution containing 5wt% silane coupling agent, react at 80°C for 2h, and filter to obtain the treated SiO 2 Microspheres;

[0038] S2. Preparation of plant extract solution: Wash 10g Coptidis Rhizoma, 15g Artemisia argyi, 5g Sophora flavescens, 5g Angelica dahurica, 5g Poria cocos, and 10g Atractylodes atractylodes, respectively, wash, dry, and pulverize to below 100 mesh, and add them according to the solid-liquid ratio of 1:10g / mL In deionized water, heated to boiling and extracted for 5 hours, filtered, and the filtrate was evaporated under reduced pressure to a relative density of 2 to obtain a plant extract solution;

[0039] S3, preparation of composite nanomaterials: 5g of plant extract solution, 10g of SiO after step S1 treatment 2 Add microspheres, 2g coupling agent, and 1g surfactant to the shear disperser in turn, raise ...

Embodiment 3

[0042] Embodiment 3 plant source PP masterbatch

[0043] S1, TiO 2 Microsphere treatment: 12g TiO 2 Add the microspheres to 70g of an aqueous solution containing 3.5wt% silane coupling agent, react at 65°C for 1.5h, and filter to obtain the treated TiO 2 Microspheres;

[0044] S2. Preparation of plant extract solution: Wash 7g Coptidis Rhizoma, 12g Artemisia argyi, 3g Sophora flavescens, 3g Angelica dahurica, 3g Poria cocos, and 7g Atractylodes atractylodes, respectively, wash, dry, and crush to below 100 mesh, and add them according to the solid-liquid ratio of 1:7g / mL In deionized water, heated to boiling and extracted for 3 hours, filtered, and the filtrate was evaporated under reduced pressure to a relative density of 1.7 to obtain a plant extract solution;

[0045] S3, preparation of composite nanomaterials: 3g of plant extract solution, 7g of TiO after step S1 treatment 2 Microspheres, 1.5g coupling agent, and 0.7g surfactant were sequentially added to the shear disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com