Precursor for superhydrophobic composite material coating and preparation method thereof

A composite material and superhydrophobic technology, which is applied in the field of superhydrophobic composite material coating precursor and its preparation, can solve the problems of poor durability and weak interface interaction of superhydrophobic coatings, and achieve outstanding impact resistance and strong interaction , the effect of restoring superhydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Under stirring conditions, 1.0 g of ACNTB particles were added to the mixed solution of 9.1 g of ammonia water and 110 g of ethanol. After stirring for 10 min, a mixed solution of 9.35 g of TEOS and 40 g of ethanol was added dropwise, heated in a water bath at 60 °C, and 2.5 g of ethanol was added after stirring for 18 h. g of KH570, continue to stir for 6h, the reaction ends, cool to room temperature naturally, the obtained suspension is washed with ethanol and centrifuged three times, and ACNTB-SiO is collected 2 -KH570 particles, then after drying in a vacuum oven at 60 °C for 12 h to obtain black ACNTB-SiO 2 -KH570 granules.

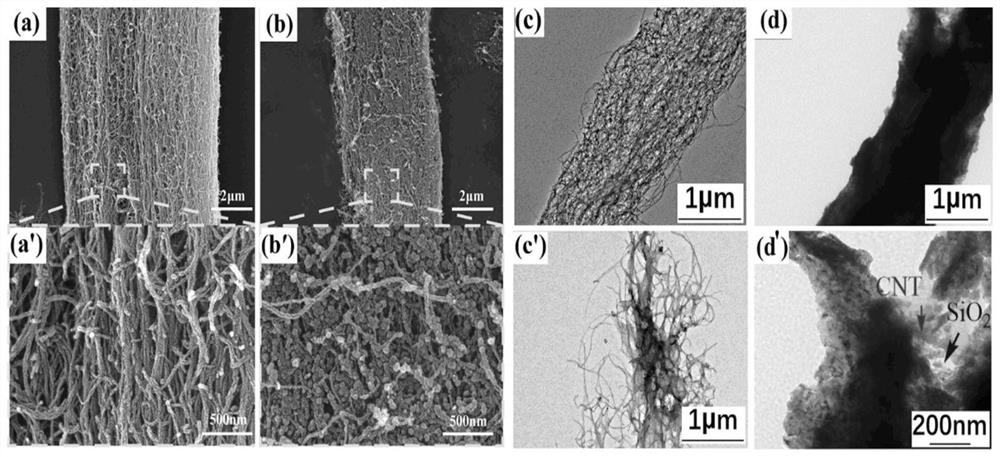

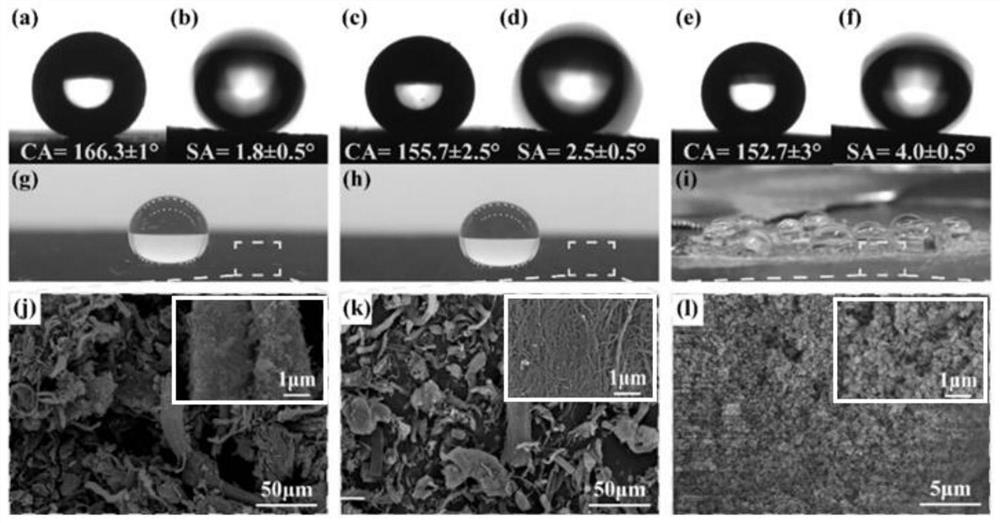

[0036] figure 1 are ACNTB, ACNTB-SiO in Example 1 of the present invention 2 -KH570 Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) photographs. from figure 1 It can be seen in a, 1a' and 1c that the CNTs in ACNTB have a certain orientation arrangement, and there are obvious entanglements between CNTs. In addi...

Embodiment 2

[0056] Under stirring conditions, 1.0 g of ACNTB particles were added to the mixed solution of 9.1 g of ammonia water and 110 g of ethanol. After stirring for 10 min, a mixed solution of 9.35 g of TEOS and 40 g of ethanol was added dropwise, heated in a water bath at 60 °C, stirred at a constant speed for 18 h, and then added with 2.5 g of ethanol. g of KH570, continue to stir for 6h, the reaction ends, cool to room temperature naturally, the obtained suspension is washed with ethanol and centrifuged three times, and ACNTB-SiO is collected 2 -KH570 particles, then after drying in a vacuum oven at 60 °C for 12 h to obtain black ACNTB-SiO 2 -KH570 granules.

[0057] At 30°C, 2g epoxy resin (E-51), 0.02g ACNTB-SiO 2 -KH570, 0.6g DGETPDMS (colorless and transparent liquid, viscosity (25°C) 5000 mPa.s, specific gravity (25°C) 1.08), 0.88g HBPSi are mixed uniformly and maintained for 10 minutes to obtain a resin adhesive prepolymer, and then the adhesive The prepolymer was uniform...

Embodiment 3

[0070] Under stirring conditions, 2.0 g of ACNTB particles were added to the mixed solution of 12 g of ammonia water and 150 g of ethanol. After stirring for 10 min, the mixed solution of 14 g of TEOS and 50 g of ethanol was added dropwise, heated in a water bath at 60 °C, and 5 g of ethanol was added after stirring for 36 h. Vinyltriethoxysilane (VTES), after stirring for 6 hours, the reaction was completed, and the suspension was naturally cooled to room temperature. The obtained suspension was washed with ethanol and centrifuged three times to collect ACNTB-SiO 2 -VTES particles, then dried in a vacuum oven at 60 °C for 12 h to obtain black ACNTB-SiO 2 -VTES particles.

[0071] At 80°C, 2g epoxy resin (E-44) and 0.6g HBPSi were mixed uniformly and maintained for 20min to obtain a resin adhesive prepolymer, and then the adhesive prepolymer was uniformly scraped on the surface of the aluminum plate substrate (adhesive prepolymer layer thickness of 70 μm), when the prepolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com