Carbon-loaded multi-metal multistage material as well as preparation method and application thereof

A technology of multi-element metals and metals, applied in the field of carbon-supported multi-element metal multi-level materials and its preparation, can solve the problem that the distance between electrochemical performance and catalytic performance is insufficient to meet the actual needs, lack of preparation methods for carbon-supported multi-element metal multi-level materials, and lack of different Problems such as the universality of metal sulfide loading, to achieve the effect of abundant reaction sites, good electrochemical performance, and multi-level structure promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

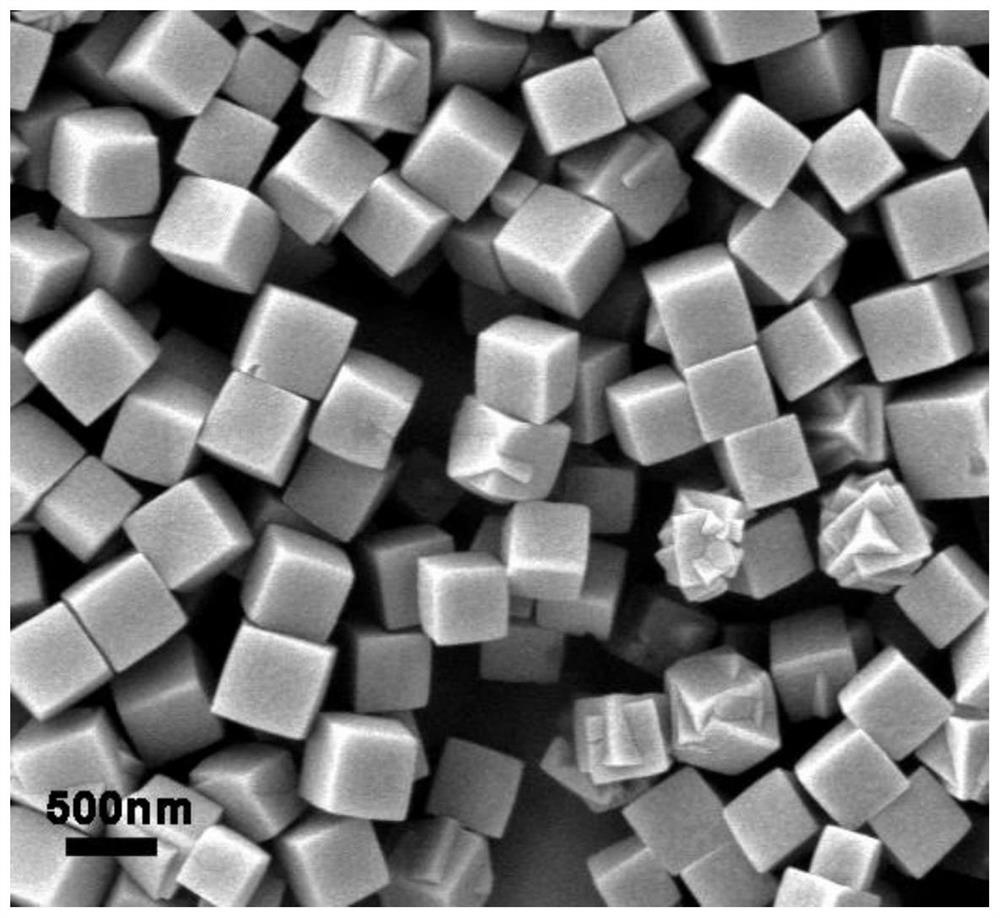

[0040] In this embodiment, the inner template is prepared by the following method: cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O, 1 mmol) and cetyltrimethylammonium bromide (CTAB, 0.0137 mmol) were dissolved in 10 ml of deionized water to form solution A. Solution B was formed by dissolving 4.54 g of 2-methylimidazole (2-MeIm) in 70 ml of deionized water. Pour solution A into solution B and stir vigorously for 20 min. After centrifugation and washing with ethanol, it was dried naturally at room temperature to obtain a purple powder, which is the inner template ZIF-67. The scanning electron microscope image of the appearance of ZIF-67 is attached figure 1 shown. From figure 1It can be seen that the catalyst described in the examples has obvious nano-cubic characteristics, the side length is about 600nm, and the surface is smooth, which proves the successful synthesis of the material.

[0041] Prepare metal salt solution, disperse sodium bicarbonate (SB, 3mM) and sodium...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that this embodiment also includes step (4) for vulcanization, as described below.

[0049] (1) Ultrasonic disperse 200mg of ZIF-67 in 35ml of ethanol, stir in a water bath at 33°C, pour into solution C, and form cobalt-tungsten metal precipitation;

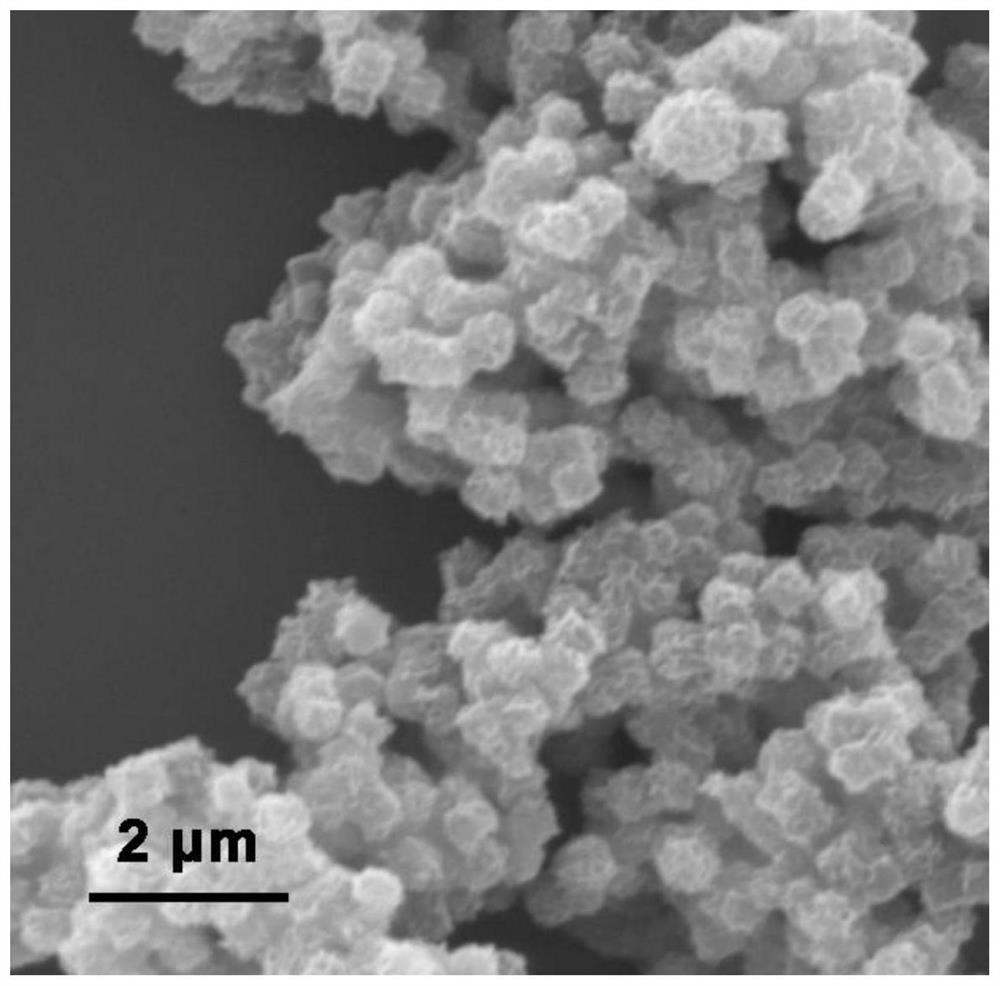

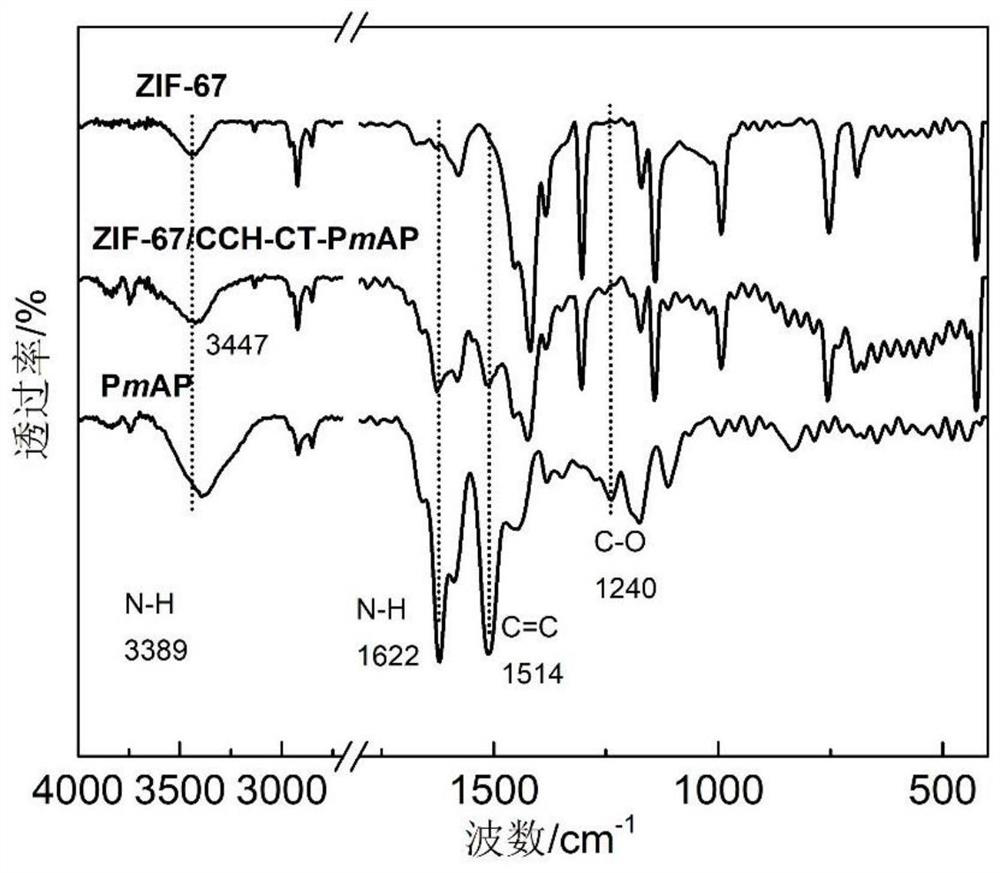

[0050] (2) Disperse meta-aminophenol (mAP, 200mg) in 10ml ethanol solution to form solution D, dissolve formaldehyde (HCHO, 0.3ml) into 10ml aqueous solution to form solution E, add solution D and solution E to step (1 ) in the solution obtained, reacted for 9 hours, centrifuged, washed and dried at room temperature to obtain a purple powder, which is the cobalt-tungsten metal precipitate ZIF-67 / CCH-CT-PmAP wrapped in a polymer.

[0051] (3) Carbonize ZIF-67 / CCH-CT-PmAP, and calcinate ZIF-67 / CCH-CT-PmAP in a tube furnace under an atmosphere of argon (flow rate of 100 sccm), with a heating rate of 2°C / min , the carbonization temperature was 500° C., and the carboni...

Embodiment 3

[0056] The difference between this embodiment and Embodiments 1 and 2 is that the inner and outer carbon layers are different, the carbonization reaction rate is different, and a hollow structure is also formed. The details are as follows.

[0057] (1) Weigh 1g of melamine and mix 1ml of formaldehyde, 0.27g of polyvinyl alcohol and 45ml of deionized water, add 5ml of aqueous solution in a water bath at 80°C and mix with 10mM and 20mM zinc chloride. After the solution became turbid, react for 8-10min. Centrifugal washing obtains melamine formaldehyde resin.

[0058] (2) Redisperse 0.5g of melamine-formaldehyde resin in 50ml of aqueous solution, add 100mg of dopamine hydrochloride, 0.695g of ferrous sulfate and 0.297g of cobalt chloride in an aqueous solution and react in a water bath at 60°C for 24 hours. The surface is covered with a layer of polydopamine, and at the same time, two metal sources of cobalt and iron are mixed.

[0059] (3) Under an argon atmosphere, heat up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com