Method for monitoring working state of blast-furnace tuyere

A technology of working status monitoring and working status, which is applied in the direction of neural learning methods, still image data retrieval, instruments, etc., can solve the problem that the abnormal condition of the tuyere cannot be monitored in real time, and achieve the reduction of working time and labor costs, high accuracy, and The effect of realizing the automation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

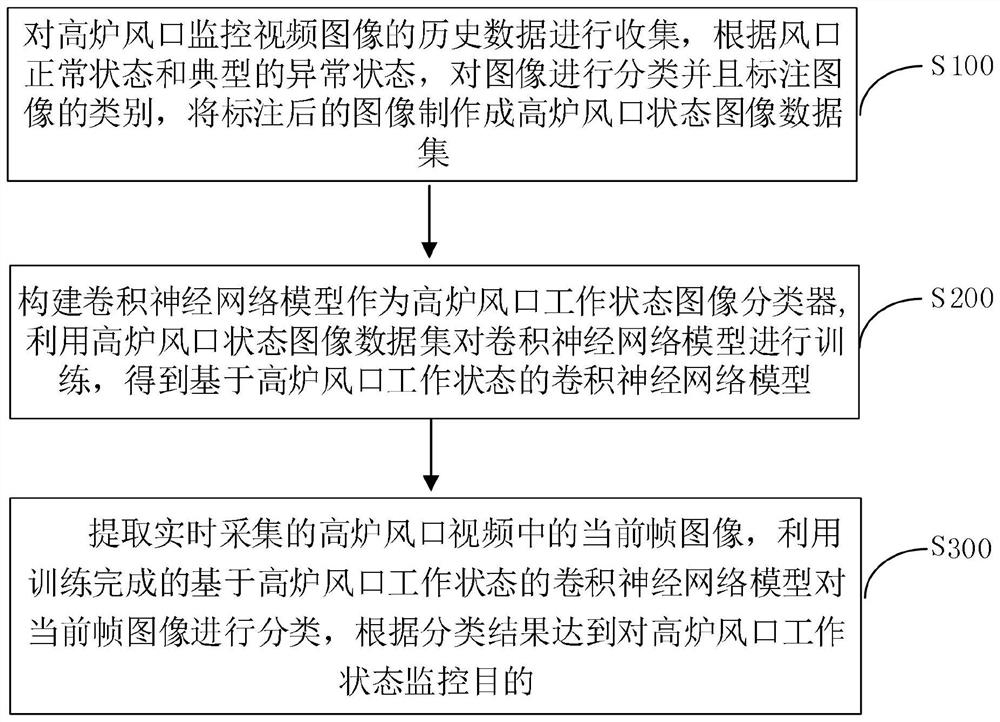

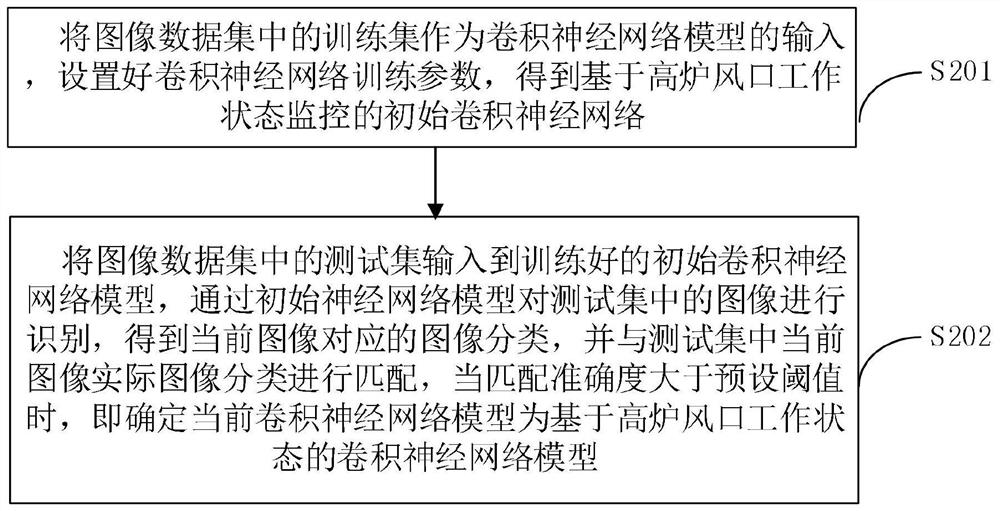

[0031] A method for monitoring the working state of a blast furnace tuyere, comprising:

[0032] S100. Collect historical data of blast furnace tuyere monitoring video images, classify the images and mark the image categories according to the normal state and typical abnormal state of the tuyere, and make the marked images into a blast furnace tuyere state image data set.

[0033] In some preferred embodiments, S100 specifically includes: classifying and labeling images of blast furnace tuyeres, classifying images, including normal situations and abnormal situations; The data is divided into two parts, one part is the training set, which is used to train the image classifier; the other part is the test set, which is used to test the classification effect of the image classifier.

[0034] Specifically, a specific plant or blast furnace may be used to collect video from an imager for tuyere, and video images of the tuyere of the blast furnace may be collected. Abnormal conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com