Full-automatic hole punching machine for building steel pipes

A fully automatic, punching machine technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as low efficiency, troublesome installation of magnetic drills, waste of manpower and material resources, etc., to achieve Guarantee the degree of precision and efficiency, reduce the incidence of accidents, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

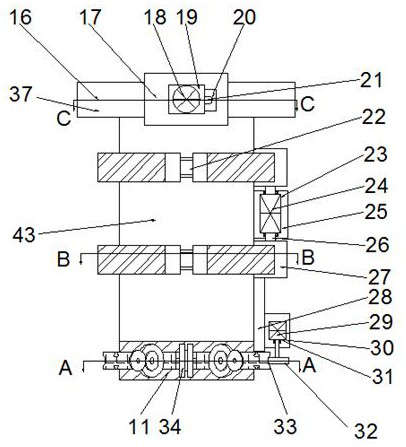

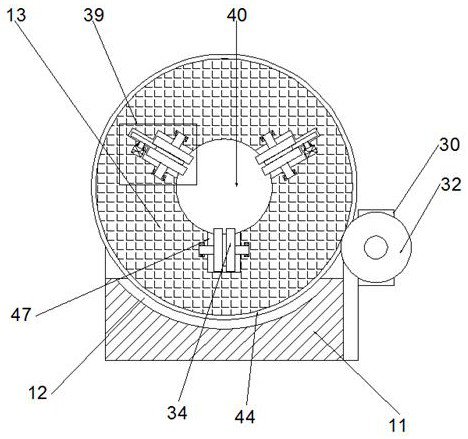

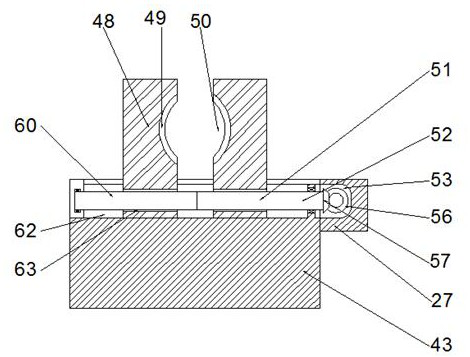

[0020] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] A fully automatic drilling machine for construction steel pipes described in conjunction with accompanying drawings 1-6, including a base 43 and a drilling device 37, the lower end of the base 43 is fixed with a low base 11, and the front end of the low base 11 has an opening The forward main slideway 12, the rotatable sleeve 13 is slidably installed in the main slideway 12, and the circumferential position of the rotatable sleeve 13 has an outward sleeve gear cavity 44, and the sleeve gear cavity A sleeve gear 33 is fixedly installed in 44, and the sleeve gear 33 meshes with the driving sleeve gear 32 fixedly installed at the bottom end of the main slide motor 29 rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com