Arc-shaped stamping die for metal plate

An arc and die technology, applied in the field of sheet metal stamping arc dies, can solve the problems of excessive deformation of sheet metal parts, increased scrap rate, stamping failure, etc., to reduce the die speed, reduce scrap rate, and slow down the movement speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

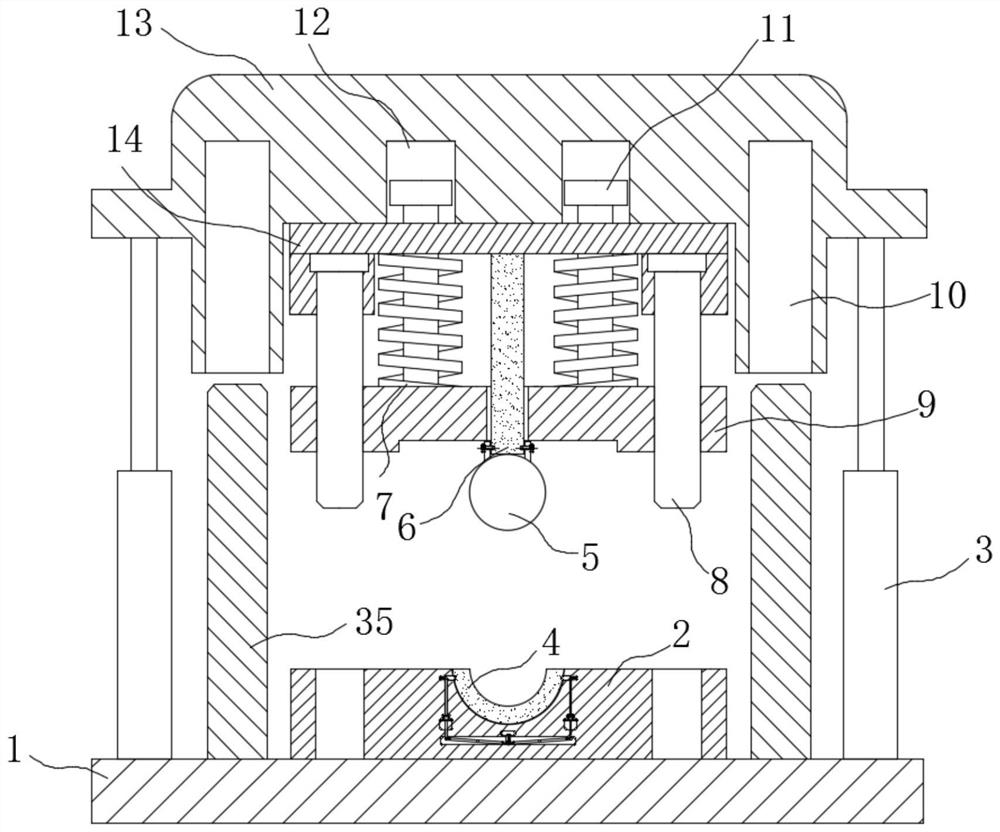

[0037] As an embodiment of the present invention, the detachable mechanism includes a snap-fit mechanism, a reset mechanism, a lever mechanism and an adjustment mechanism;

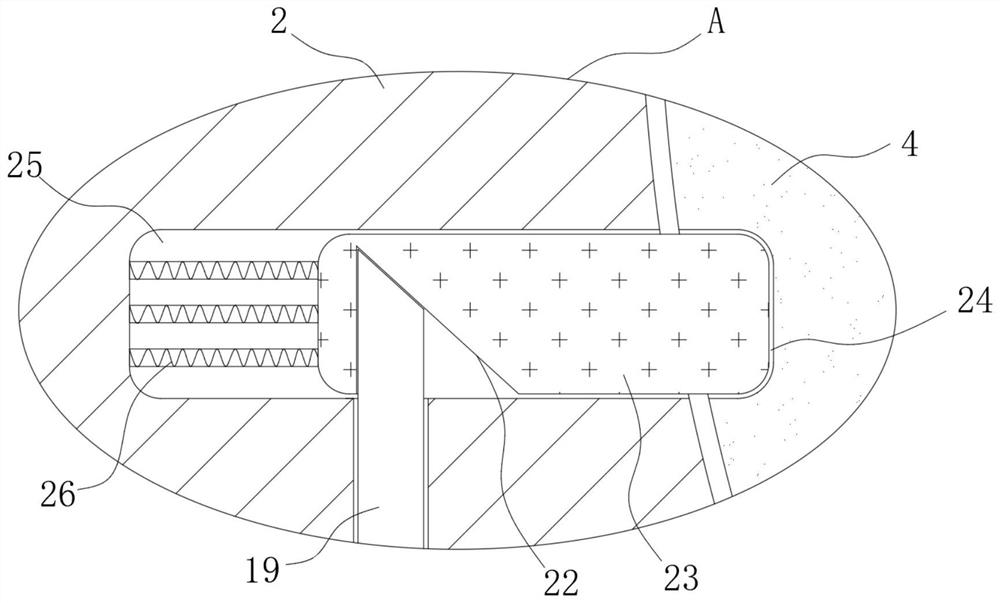

[0038] The engaging mechanism includes a plurality of grooves 25 symmetrically provided on the lower mold base 2, and a plurality of connecting springs 26 are installed in each groove 25, and a plurality of connecting springs 26 are fixedly connected with blocks 23, so that The engaging mechanism also includes a plurality of draw-in grooves 24 symmetrically opened on the outer wall of the arc-shaped die 4, and the draw-in blocks 23 are set in the draw-in slots 24 corresponding to the position, and each of the draw-in blocks 23 is provided with an oblique slot 22;

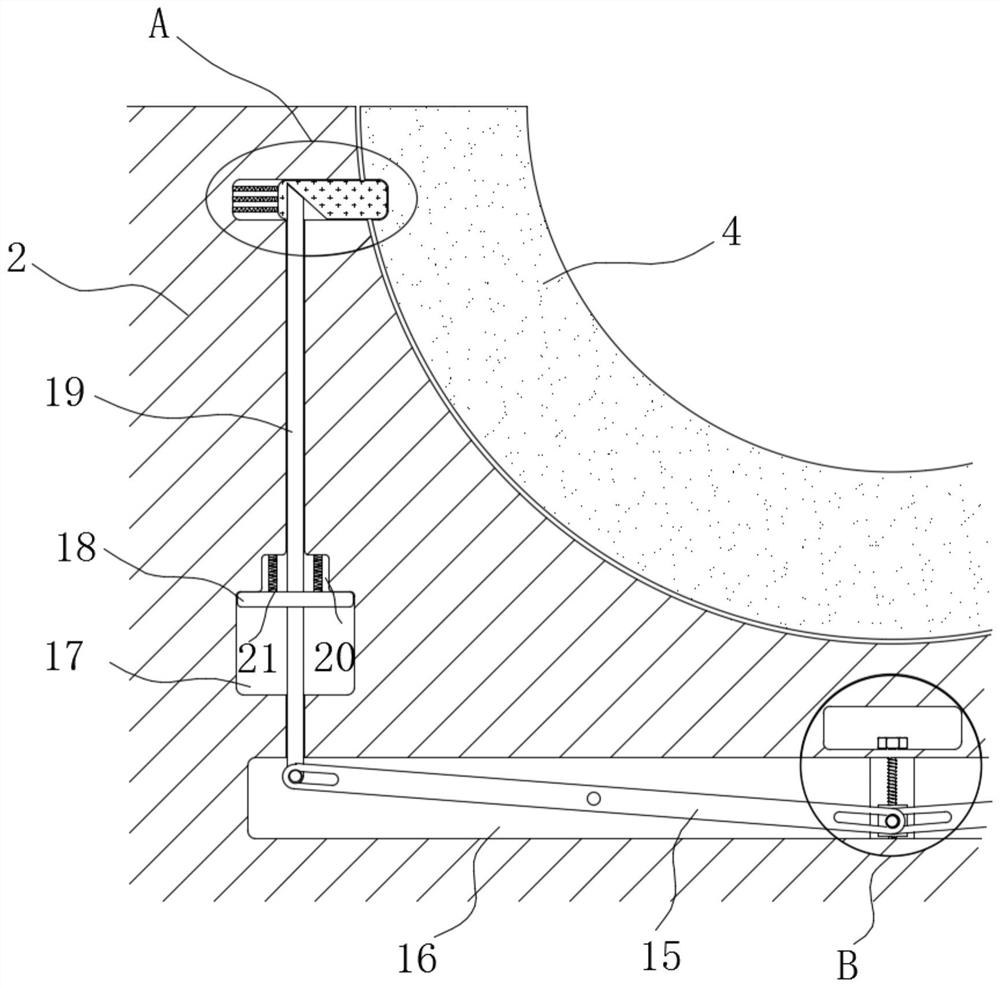

[0039] The reset mechanism includes a plurality of moving chambers 17 and reset chambers 20 symmetrically opened on the lower mold base 2, and each moving chamber 17 communicates with a corresponding reset chamber 20, and multiple A back-movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com