A combined aluminum alloy thermal insulation door and window

An aluminum alloy, combined technology, applied in the field of aluminum alloy doors and windows, can solve the problems of ventilation, lighting, sound insulation and space switching at the same time, and achieve the effect of improving thermal insulation and increasing glass thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

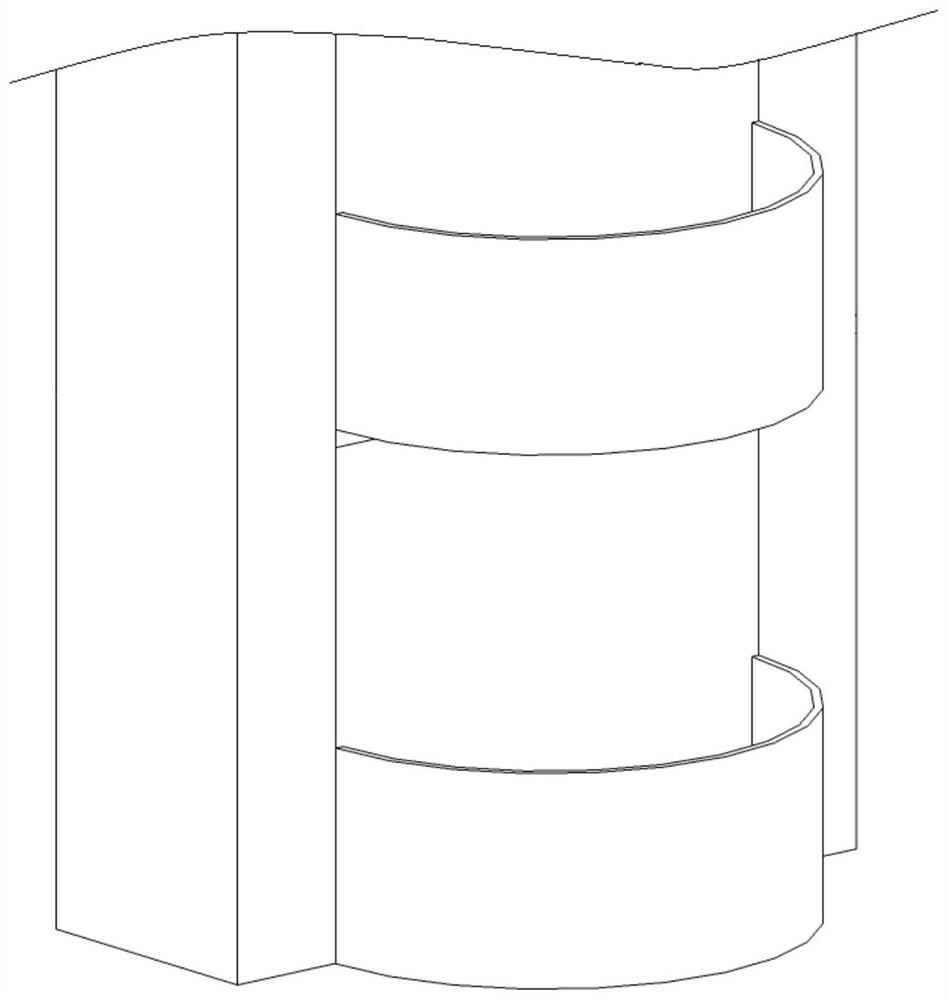

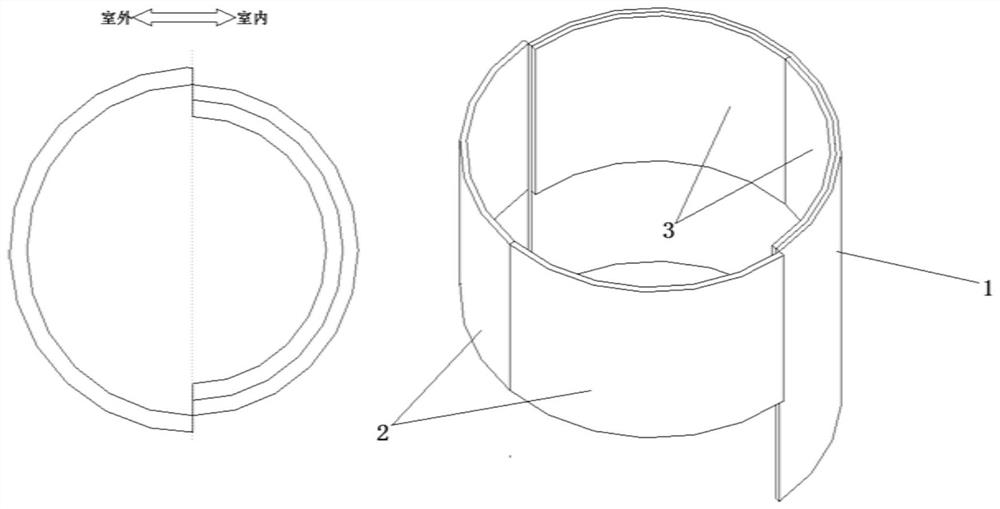

[0055] Such as figure 2 , pointing to the indoor direction from the outside of the semi-circular balcony, the first aluminum alloy window frame 2, the aluminum alloy door frame 1 and the second aluminum alloy window frame 3 are arranged in sequence, and the upper and lower ends of the first aluminum alloy window frame 2 are connected with the second guide rail , the upper end of the second aluminum alloy window frame 3 is higher than the upper end of the balcony railing. In this arrangement, the aluminum alloy doors and windows are in the sound insulation mode, and the two first aluminum alloy window frames 2 close the arc-shaped balcony, and the first aluminum alloy window frame 2, the aluminum alloy door frame 1 and the second aluminum alloy window frame 3 form a closed cylinders to insulate the interior from the exterior.

Embodiment 2

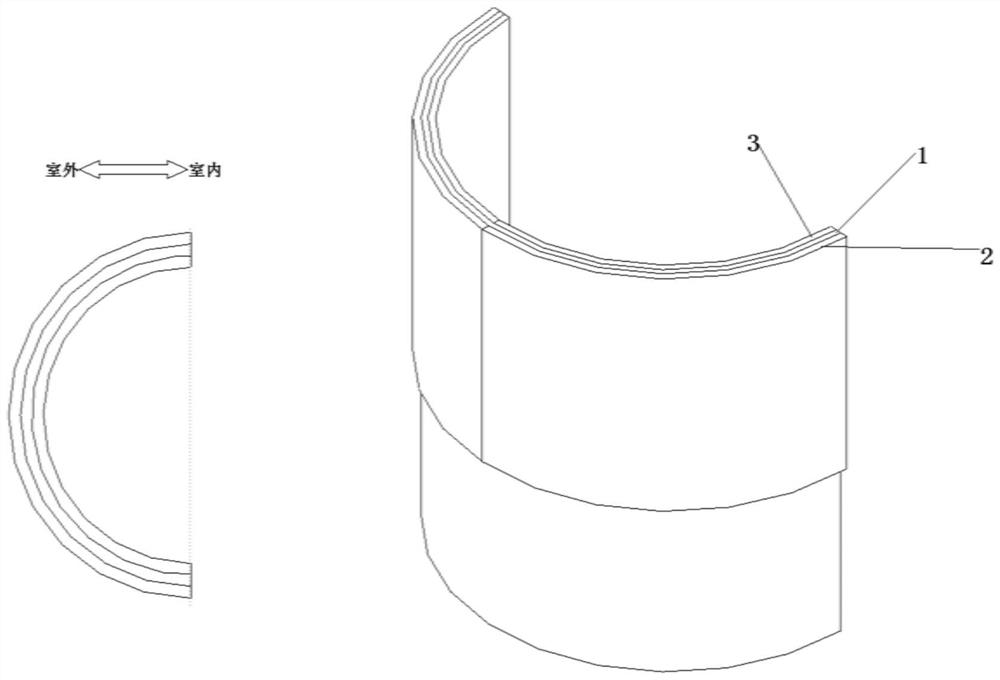

[0057] Such as image 3 , pointing to the indoor direction from the outside of the semi-circular arc balcony, the first aluminum alloy window frame 2, the aluminum alloy door frame 1 and the second aluminum alloy window frame 3 are arranged in sequence (at this time the second aluminum alloy window frame 3 moves upward), and the first The upper and lower ends of the aluminum alloy window frame 2 are connected to the second guide rail, the aluminum alloy door frame 1 has no overlapping area with the semicircular balcony, and the upper end of the second aluminum alloy window frame 3 is higher than the upper end of the balcony railing. In this arrangement, the aluminum alloy doors and windows are in the thermal insulation mode. Since there is a gap between the first aluminum alloy window, the aluminum alloy door and the second aluminum alloy window, an isolation structure of three layers of glass barriers and two layers of air gaps is formed. The length of the circulation channel...

Embodiment 3

[0059] Such as Figure 4 , pointing to the indoor direction from the outside of the semi-circular arc balcony, the second aluminum alloy window frame 3, the aluminum alloy door frame 1 and the first aluminum alloy window frame 2 are arranged in sequence (the second aluminum alloy window frame 3 is located above), and the aluminum alloy door frame 1 There is no overlapping area with the semi-circular balcony, and the upper end of the second aluminum alloy window frame 3 is at the same height as the upper end of the balcony railing. In this arrangement, the aluminum alloy doors and windows are in the open mode, the balcony is not closed, and the indoor air is ventilated through the ventilation holes on the aluminum alloy door frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com