Ultraviolet-cured white butyl coating as well as preparation method and application thereof

An ultraviolet light and coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor toughness, brittle paint film, poor impact resistance, etc. The effect of focus, excellent compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

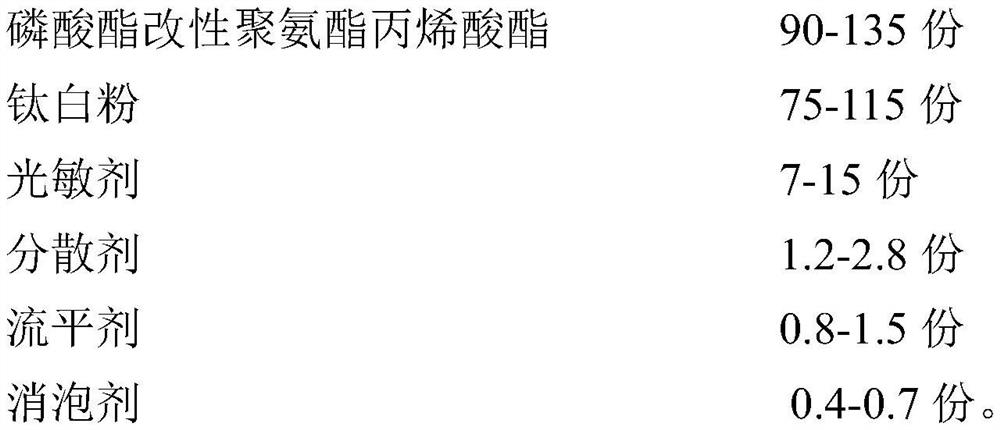

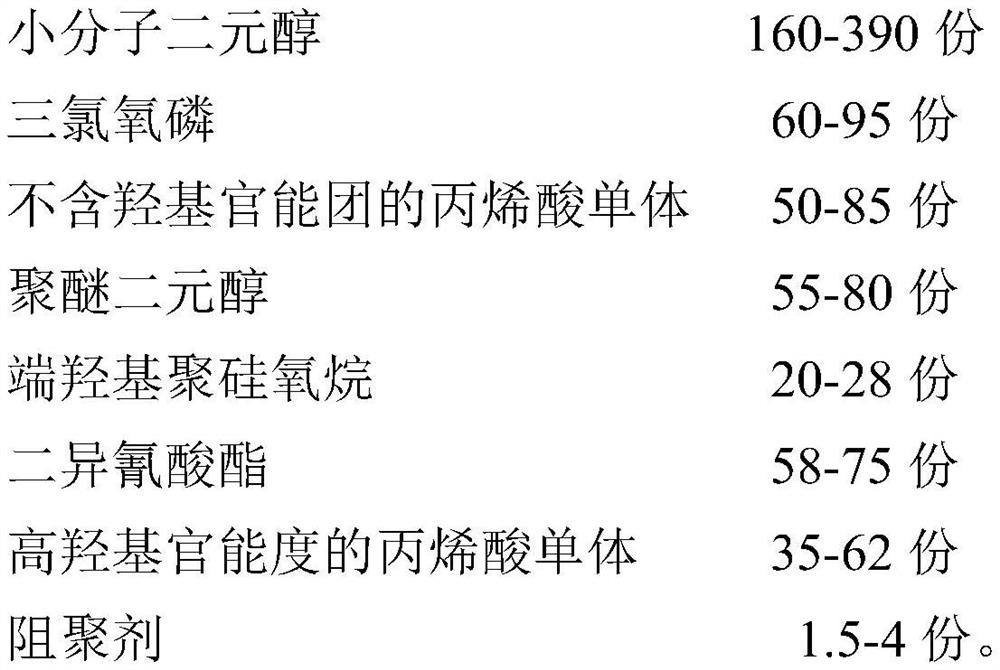

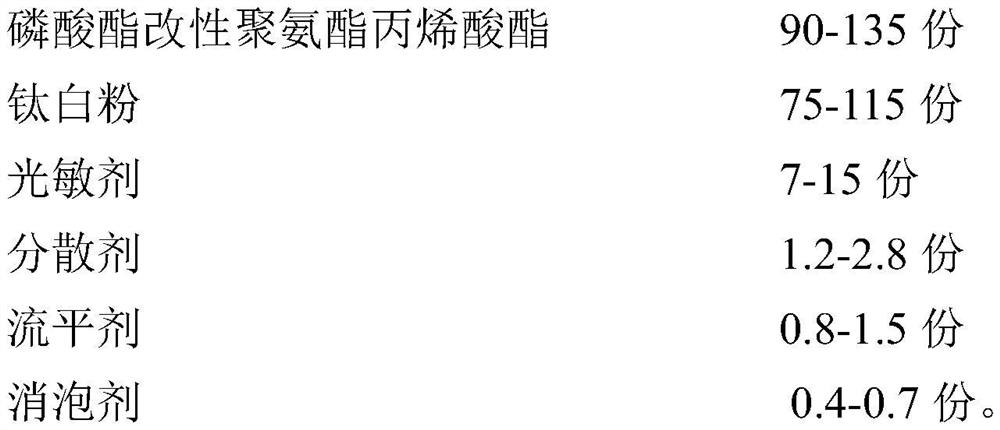

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the synthesis of phosphoric acid ester modified polyurethane acrylate PUA01

[0037] The first step, add 160g of diethylene glycol into the reaction kettle with a stirrer and a gas outlet device, the gas outlet is connected to 10% aqueous sodium hydroxide solution, and when the temperature is controlled at 30°C, add dropwise 60g of phosphorus oxychloride, the rate of addition is 1ml / min. After the dropwise addition, the temperature was raised to 60° C. to continue the reaction for 5 hours to obtain intermediate 1.

[0038] In the second step, Intermediate 1 is transferred to a device equipped with a reflux device, under nitrogen protection, 50g of butyl acrylate is added, the temperature is raised to 75°C, 55g of polypropylene glycol (Mn=1000Da) and 20g of Hydroxyl-terminated polysiloxane (Mn=1000Da), stirred for 0.5 hours, slowly added dropwise 58g of toluene diisocyanate at a rate of 0.5ml / min, after the dropwise addition, continued to react for 2 hours...

Embodiment 2

[0043] Synthesis of Phosphate Ester Modified Polyurethane Acrylate PUA02:

[0044] The first step, add 390g of triethylene glycol into the reaction kettle with a stirrer and a gas outlet device, the gas outlet is connected to 10% aqueous sodium hydroxide solution, and when the temperature is controlled at 45°C, add dropwise 95g of phosphorus oxychloride, the rate of addition is 3ml / min. After the dropwise addition, the temperature was raised to 80° C. to continue the reaction for 3 hours to obtain Intermediate 1.

[0045] In the second step, the intermediate 1 is transferred to a device equipped with a reflux device, under nitrogen protection, 85g of n-octyl acrylate is added, the temperature is raised to 85°C, and 80g of polytetrahydrofuran diol (Mn=5000Da) is added And 28g of hydroxyl-terminated polysiloxane (Mn=5000Da), stirred for 0.5 hours, slowly added dropwise 75g of xylene methane diisocyanate, the drop rate was 2.5ml / min, after the dropwise addition, continued to rea...

Embodiment 3

[0050] Synthesis of Phosphate Ester Modified Polyurethane Acrylate PUA03:

[0051] The first step, add 240g of tetraethylene glycol into the reaction kettle with a stirrer and a gas outlet device, connect the gas outlet to 10% aqueous sodium hydroxide solution, and when the temperature is controlled at 35°C, add dropwise 75g of phosphorus oxychloride, the rate of addition is 1.5ml / min. After the dropwise addition, the temperature was raised to 70° C. to continue the reaction for 4 hours to obtain intermediate 1.

[0052] In the second step, the intermediate 1 is transferred to a device equipped with a reflux device. Under the protection of helium, 60g of n-octyl acrylate is added, the temperature is raised to 80°C, and 65 parts by mass of polypropylene glycol (Mn=2000Da ) and 25g of hydroxyl-terminated polysiloxane (Mn=2000Da), stirred for 1 hour, slowly added dropwise 62g of terexylylene diisocyanate, the dropping rate was 1ml / min, after the dropwise addition, continued to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com