Electrode plate and preparation method and application thereof

An electrode pole piece and pole piece technology, which is applied in the field of electrode pole piece and its preparation, can solve the problems of difficulty in obtaining uniformly coated electrolyte samples, battery performance decline, large interface resistance, etc., and achieve excellent electrochemical performance and reduce interface resistance. resistance, the effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

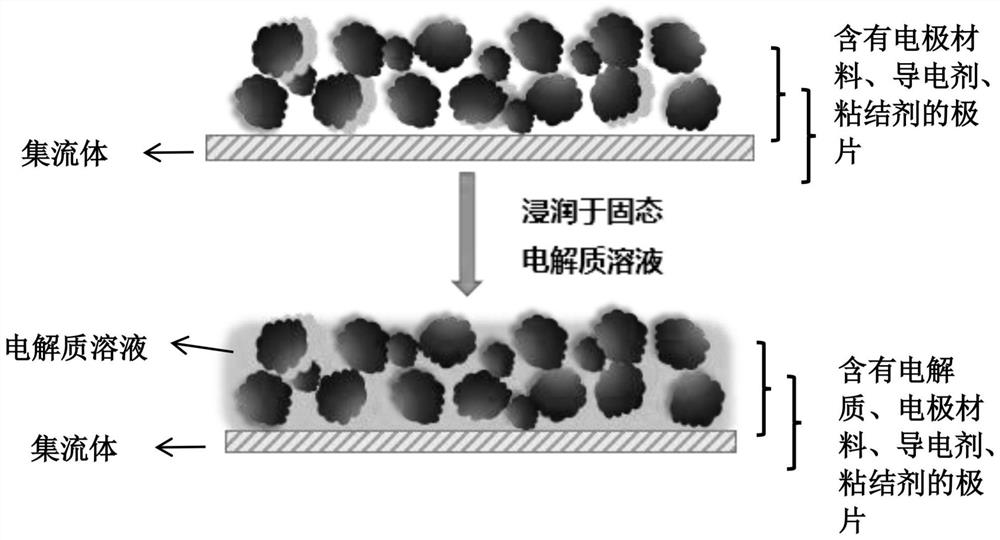

[0042] The invention provides a method for preparing electrode pole pieces, such as figure 1 shown, including the following steps:

[0043] Electrode material pole piece preparation: in parts by weight, 90-96 parts of electrode material, 0.1-5.0 parts of conductive agent, 1.0-4.0 parts of binder, and 1.0-4.0 parts of pore-forming agent are dissolved in the dispersant to obtain Slurry with a solid content of 40-70%, after the slurry is coated on the surface of the current collector, the coating amount is 1-100mg / cm 2 , drying at a temperature of 60-130°C for 0.5-2 h to obtain electrode material pole pieces;

[0044] Preparation of electrolyte solution: 40-55 g of solid electrolyte is subjected to mechanical wet ball milling to obtain electrolyte powder. The medium of wet ball milling is acetonitrile or absolute ethanol, and the mass ratio of solid electrolyte, balls and acetonitrile or absolute ethanol is 1:( 0.8-1.5): (0.8-1.2), the ball milling speed is 100-1000rpm, the bal...

Embodiment 1

[0058] A method for preparing an electrode pole piece, comprising the following steps:

[0059] S1, preparation of electrode material pole piece, 95g lithium cobaltate material, 2.0g conductive agent carbon black, 2.0g binder polyvinylidene fluoride, 90g dispersant N-methylpyrrolidone and 10g pore-forming agent oxalic acid were stirred to obtain a solid A slurry with a content of 55%, and then the slurry is coated on the surface of the current collector aluminum foil, and the coating amount is 30 mg / cm 2 , dried at 115°C for 1 h to obtain electrode material pole pieces, wherein the electrode material is LiCoO 2 ;

[0060] S2, preparation of electrolyte solution: 40g sulfide solid electrolyte amorphous Li 2 S-P 2 S 5 Perform mechanical wet ball milling to obtain electrolyte powder, dissolve the ball-milled electrolyte powder in an organic solvent-absolute ethanol to obtain an electrolyte solution, and stir evenly with a magnetic force to obtain an electrolyte solution. The ...

Embodiment 2

[0063] A preparation method of an electrode pole piece is carried out according to the method in Example 1, the difference is that

[0064] S1, preparation of electrode material pole pieces, 90g positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 , 1.0g conductive agent single-walled carbon nanotubes, 4.0g binder polyvinylidene fluoride, 51.2g N-methylpyrrolidone dispersant and 5 g pore-forming agent-citric acid were stirred to prepare a slurry with a solid content of 66% , and then apply the slurry on the surface of the current collector aluminum foil, the coating amount is 7mg / cm 2 , dried under vacuum at 105°C for 2 h to obtain pole pieces of electrode materials;

[0065] S2, preparation of electrolyte solution: 50g NASICON type solid electrolyte Li Zr 2 (PO 4 ) 3 Carry out mechanical wet ball milling to obtain electrolyte powder, the electrolyte powder after ball milling is dissolved in organic solvent ethanol to obtain electrolyte solution, stir evenly, obtain e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com