Barium titanate-based superparaelectric film as well as low-temperature preparation method and application thereof

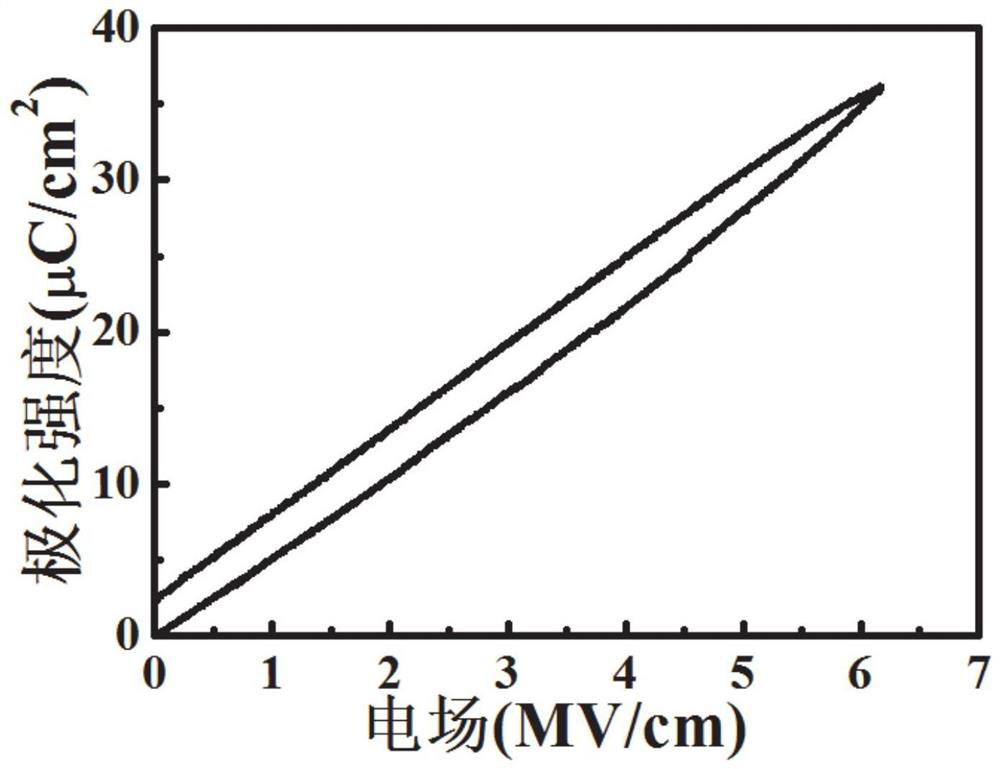

A barium titanate and paraelectric technology, which is applied in the field of barium titanate-based superparaelectric film and medium and low temperature preparation, can solve the problems of low energy density of recyclable capacitors, low dielectric constant of capacitor density, restricting the development of thin film transistors, etc. Effects of frequency stability, excellent energy storage characteristics, and small residual polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

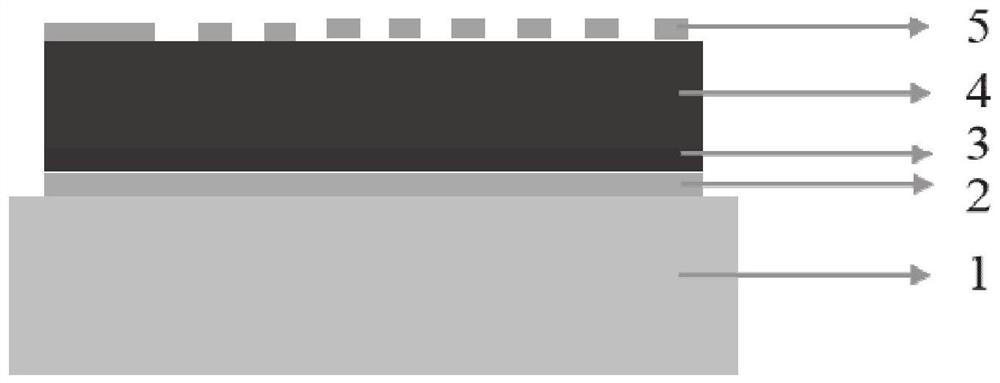

[0030] In the first aspect, the present invention provides a method for preparing a barium titanate-based superparaelectric film at a medium and low temperature, comprising the following steps:

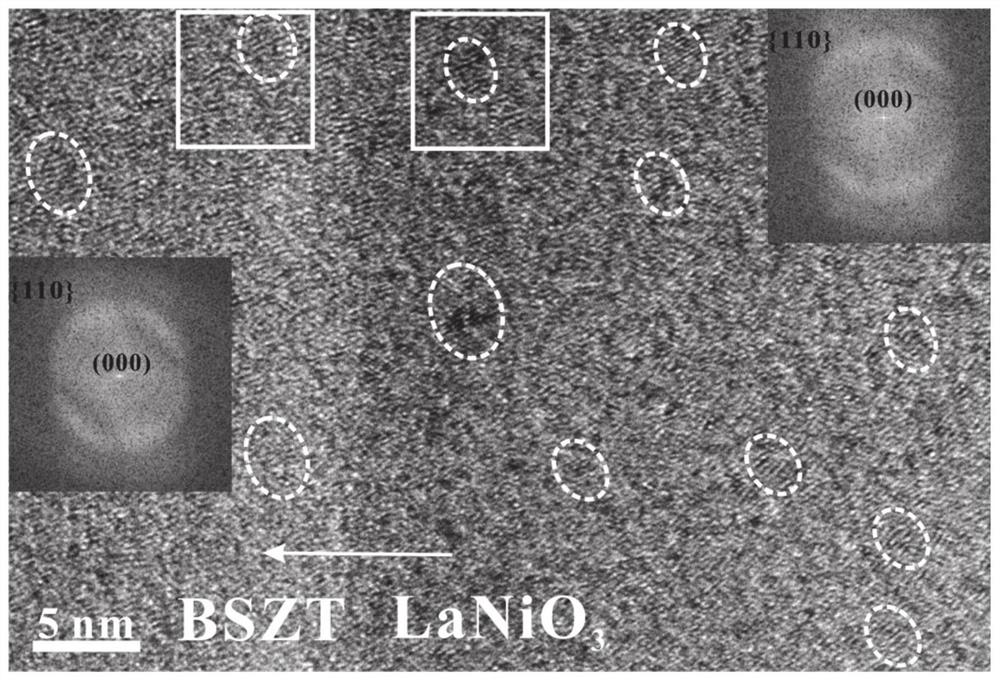

[0031] A buffer layer of lanthanum nickelate and a base film of barium titanate are sequentially sputtered on a silicon substrate with a bottom electrode, and the deposition temperature is 25-150° C. to obtain the finished product.

[0032] Preliminary studies have found that lanthanum nickelate can effectively reduce the crystallization temperature of the sputtered barium titanate-based film. When the sputtering temperature in the above steps is 200°C or above, the barium titanate base film will form columnar nano-grains that run through the thickness of the film, thereby presenting a ferroelectric state, making the withstand voltage (breakdown) of the barium titanate base film Voltage) decreases and remnant polarization increases, corresponding to lower recoverable energy storage de...

Embodiment 1

[0055] (a) Treatment of the substrate

[0056] Semiconductor Si / SiO 2 As the substrate, put the substrate into the sample tray, and finally put the sample tray into the sample tray rack of the vacuum coating chamber;

[0057] Vacuuming: close the vacuum chamber, evacuate, and make the air pressure in the chamber to 2×10 -4 Pa;

[0058] Heating: Ar gas is introduced into the chamber, and then the substrate is heated until the temperature rises to 300°C, and then the temperature is kept stable.

[0059] (b) Preparation of the bottom electrode

[0060] Titanium and platinum metals were used as sputtering targets, and the bottom electrode was deposited by radio frequency magnetron sputtering. The sputtering pressure is adjusted to 0.3Pa, the sputtering power is 55W, and the Si / SiO 2 Titanium and platinum are sequentially deposited on the substrate, and the total thickness of the bottom electrode is about 150nm.

[0061] (c) Preparation of buffer layer

[0062] Using lanthan...

Embodiment 2

[0071] The difference between this embodiment and Embodiment 1 is that in step (d), the perovskite oxide barium titanate ceramic is used as the sputtering target, the sputtering pressure is 1.2Pa, and the sputtering power is 100W barium titanate-based film Thickness is 350nm, other steps and parameter are identical with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com