BT-KBT-NN (BaTiO3-K0.5Bi0.5TiO3-NaNbO3)-based high energy storage density ceramic and preparation method thereof

A BT-KBT-NN, high energy storage density technology, applied in the field of energy storage material preparation, can solve the problem of low energy storage density, and achieve the effect of simple operation, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of BT-KBT-NN base high energy storage density ceramics, comprising the following steps:

[0030] Step 1: Prepare BT calcined powder, KBT calcined powder and NN calcined powder; wherein, BT calcined powder is obtained by the following method: according to the chemical formula BaTiO 3 , mix barium carbonate and titanium dioxide evenly and keep warm at 1150°C for 3 hours to obtain BT calcined powder; KBT calcined powder is obtained by the following method: According to chemical formula K 0.5 Bi 0.5 TiO 3 , mix potassium carbonate, bismuth oxide and titanium dioxide evenly and keep warm at 950°C for 4 hours to obtain KBT calcined powder; NN calcined powder is obtained by the following method: according to the chemical formula NaNbO 3 , mix sodium carbonate and niobium pentoxide evenly and keep warm at 850°C for 2 hours to prepare NN calcined powder;

[0031] Step 2: BT calcined powder, KBT calcined powder and NN calcined powder according to chemical ...

Embodiment 1

[0035] 1) According to the chemical formula BaTiO 3 (BT), mix barium carbonate and titanium dioxide evenly and keep warm at 1150°C for 3 hours to prepare BT calcined powder.

[0036] 2) According to chemical formula K 0.5 Bi 0.5 TiO 3 (KBT), mix potassium carbonate, bismuth oxide and titanium dioxide evenly and keep it warm at 950°C for 4 hours to obtain KBT calcined powder.

[0037]3) According to the chemical formula NaNbO 3 (NN), mix sodium carbonate and niobium pentoxide uniformly and keep it at 850°C for 2 hours to obtain NN calcined powder.

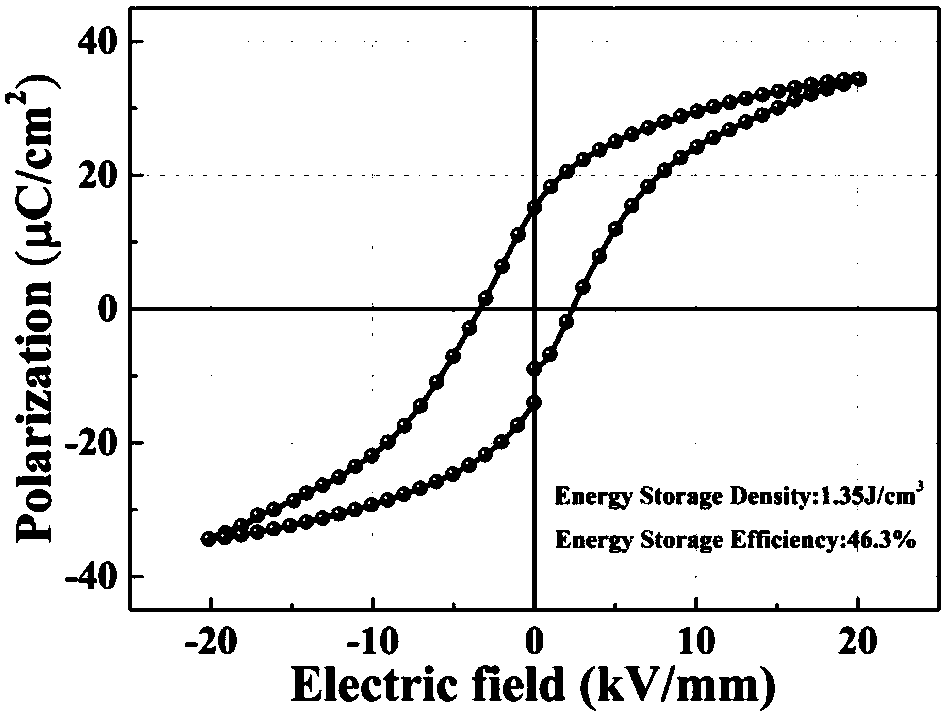

[0038] 4) BT calcined powder, KBT calcined powder and NN calcined powder according to chemical formula 0.96(0.92BaTiO 3 -0.08(K 0.5 Bi 0.5 )TiO 3 )-0.04NaNbO 3 The ingredients are mixed evenly by ball milling for 6 hours with deionized water as the ball milling medium, and then dried at 80°C. After tableting and molding, they are kept at 1160°C for 2 hours and sintered into porcelain to obtain high energy storage density ce...

Embodiment 2

[0040] 1) According to the chemical formula BaTiO 3 (BT), mix barium carbonate and titanium dioxide evenly and keep warm at 1150°C for 3 hours to prepare BT calcined powder.

[0041] 2) According to chemical formula K 0.5 Bi 0.5 TiO 3 (KBT), mix potassium carbonate, bismuth oxide and titanium dioxide evenly and keep it warm at 950°C for 4 hours to obtain KBT calcined powder.

[0042] 3) According to the chemical formula NaNbO 3 (NN), mix sodium carbonate and niobium pentoxide uniformly and keep it at 850°C for 2 hours to obtain NN calcined powder.

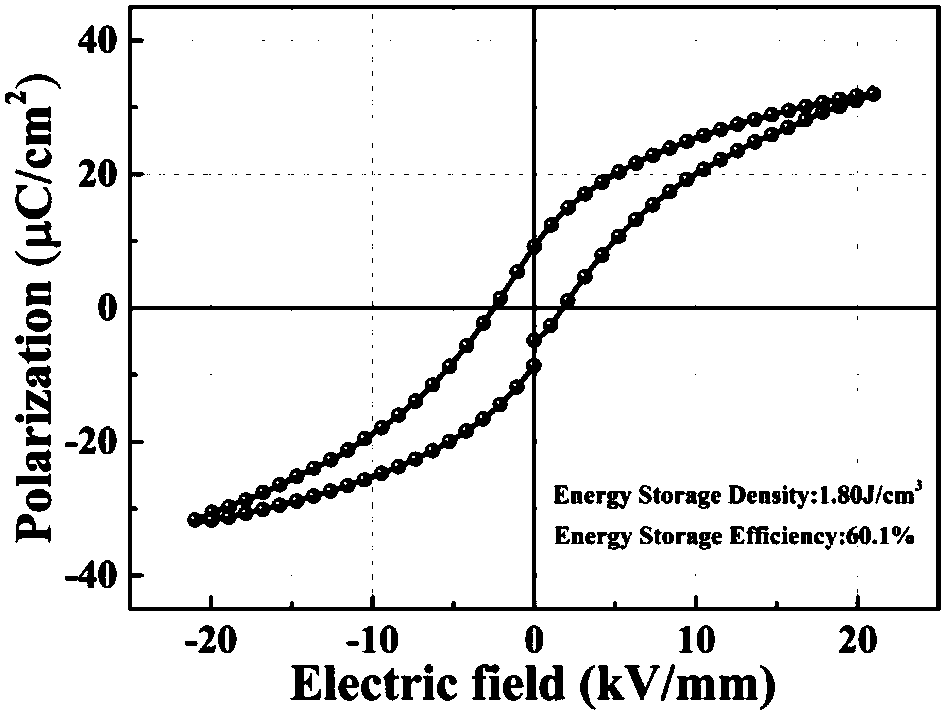

[0043] 4) BT calcined powder, KBT calcined powder and NN calcined powder according to chemical formula 0.96(0.92BaTiO 3 -0.08(K 0.5 Bi 0.5 )TiO 3 )-0.04NaNbO 3 The ingredients were mixed evenly by ball milling for 7 hours with deionized water as the ball milling medium, then dried at 80°C, pressed into tablets and formed, then sintered at 1160°C for 4 hours to obtain ceramic materials with high energy storage density.

PUM

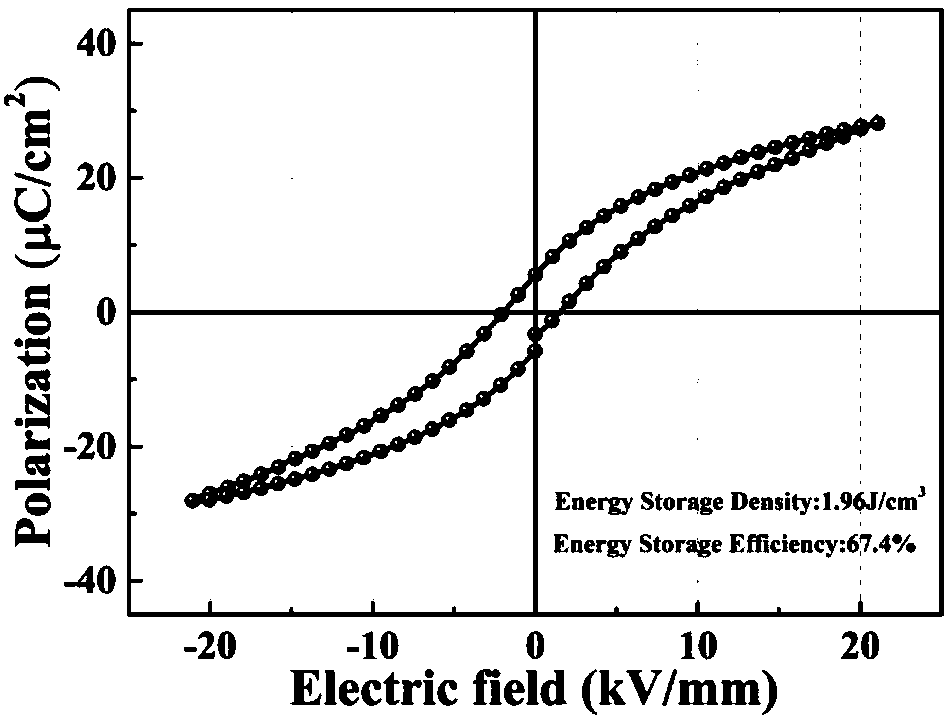

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com