Size optimization method for welded joint

A technology for welding joints and size optimization, applied in design optimization/simulation, instruments, manufacturing computing systems, etc., can solve problems such as error-prone, high computational cost, inaccurate evaluation results, etc., to improve fatigue characteristics and improve fatigue resistance. , The effect of improving the quality of welding products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

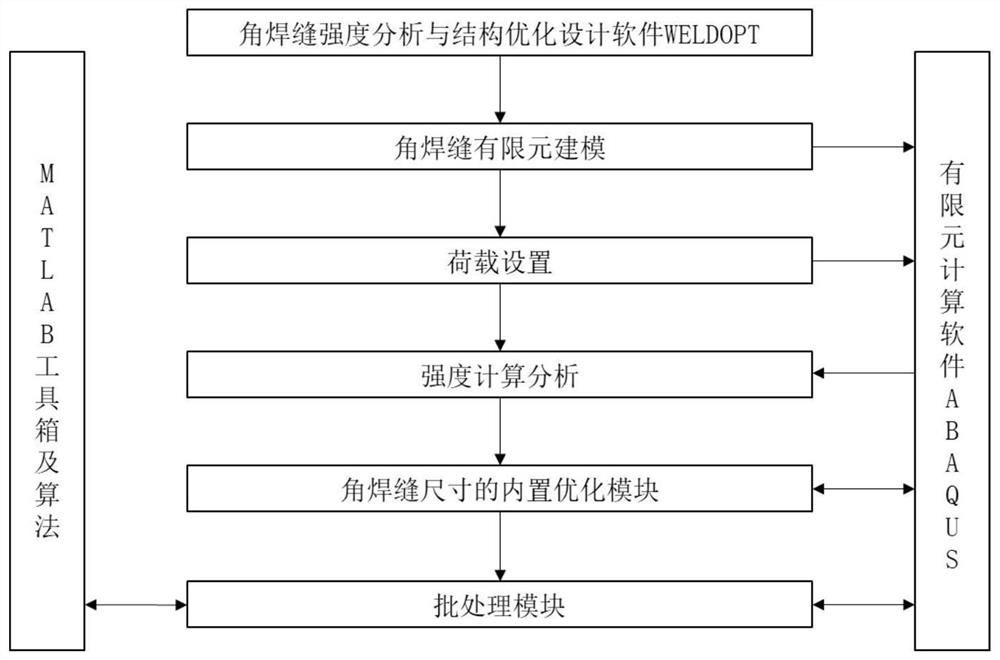

[0069] A method for optimizing the size of a welded joint proposed by the present invention, such as Figure 4 As shown in the flow chart:

[0070] (1) Build an initial proxy model for implicit problems in finite element analysis of welded structures;

[0071] (2) Create the initial sample space of the design parameters of the welded joint size;

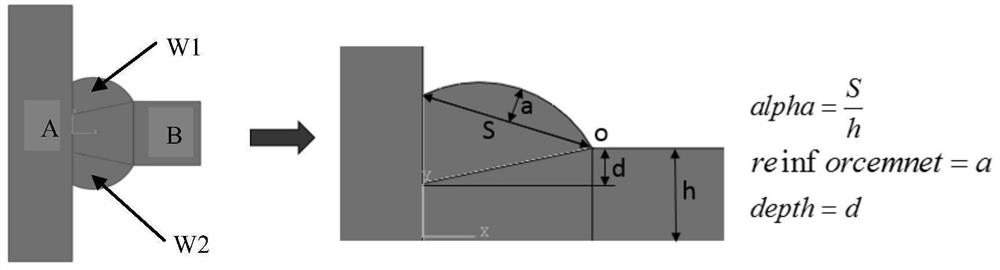

[0072] (3) According to the "Finite Element Modeling Guidelines for Welded Structures", use the sample space to create an analysis model;

[0073] (4) Use the "Efficient Calculation of Structural Stress and Evaluation Method of Fatigue Characteristics" to calculate the evaluation target;

[0074] (5) Substitute the initial sample space of the size design parameters and the obtained evaluation target response into the initial proxy model, and update the proxy model;

[0075] (6) Judging whether the accuracy of the agent model meets the self-learning and optimization capabilities, if not, go to the next step, if it is, skip to step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com