Preparation method and application of methyl nitrite

A technology of methyl nitrite and nitric acid, applied in the field of coal chemical industry, can solve the problems affecting the oxygen transmission capacity of blood and the like, achieve the effect of large-scale industrial application prospects, improve the utilization rate of raw materials and economic benefits, and improve the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

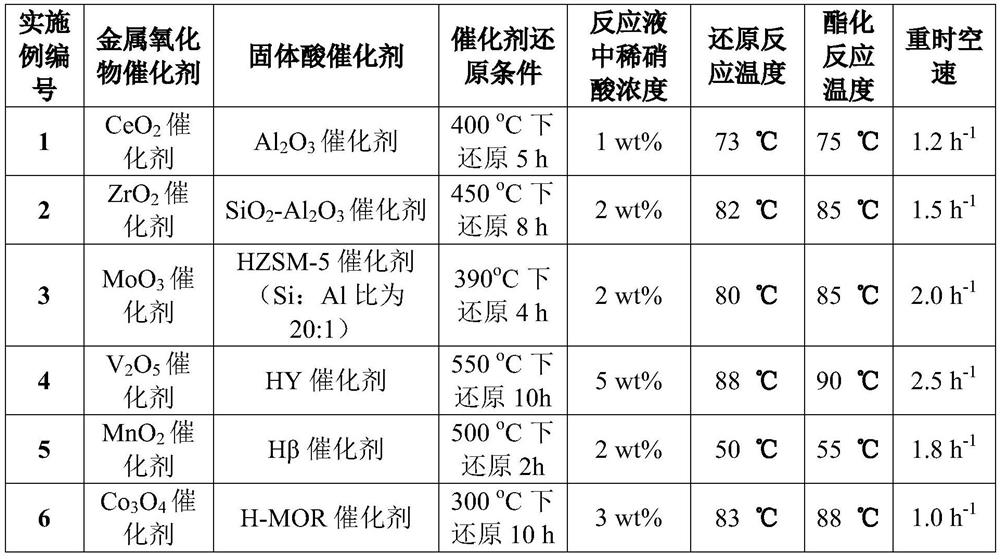

Embodiment 1

[0068] 5g CeO with a particle size of 20-30 mesh 2 Catalyst and particle size of 20 to 30 mesh 5g Al 2 o 3 The catalyst was loaded into a glass tube reactor with a diameter of 15 mm, and the catalyst was reduced at 400° C. for 5 h under a hydrogen atmosphere.

[0069] Then switch to a nitrogen atmosphere, add a reaction solution (all the rest are water) containing 1wt% nitric acid and 50wt% methyl alcohol to the fixed bed reactor with a metering pump, the upper section of the reactor is heated to 73°C to carry out the dilute nitric acid reduction reaction, and the lower section of the reactor is heated To 75 ° C for nitrosation reaction,. The weight hourly space velocity WHSV of the reaction solution is 1.2h -1 , Carry out reduction and esterification continuous reaction under atmospheric pressure nitrogen atmosphere.

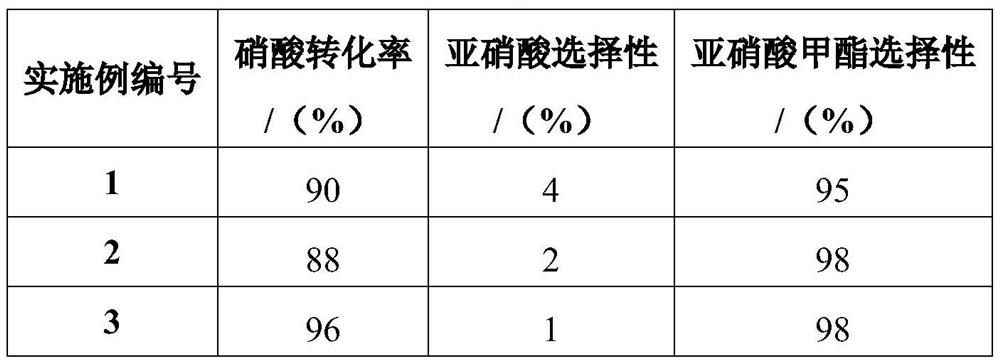

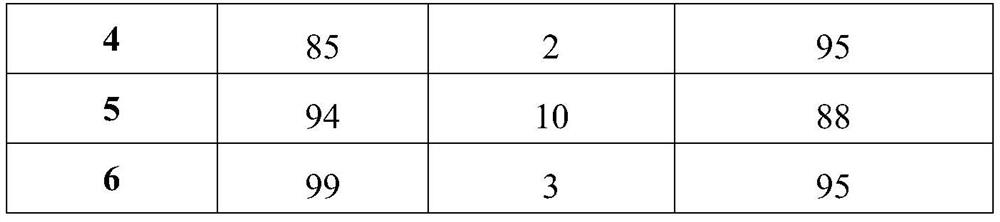

[0070] Obtained results: the conversion rate of nitric acid is 90%, the selectivity of nitrous acid is 4%, and the selectivity of methyl nitrite is 95%.

Embodiment 2

[0072] The difference with Example 1 is: the particle diameter is 20-30 mesh 5g ZrO 2 Catalyst and particle size 20-30 mesh 5g SiO 2 -Al 2 o 3 The catalyst was loaded into a glass tube reactor with a diameter of 15mm, and was reduced at 450°C for 8h under a hydrogen atmosphere. Then switch to a nitrogen atmosphere, add the reaction solution containing 2wt% nitric acid and 65wt% methanol in the fixed bed reactor with a metering pump, the upper section of the reactor is heated to 82°C to carry out the dilute nitric acid reduction reaction, and the lower section of the reactor is heated to 85°C for sub- For the reaction of nitrate esterification, the weight hourly space velocity WHSV of the reaction solution is 1.5h -1 , Carry out reduction and esterification continuous reaction under atmospheric pressure nitrogen atmosphere.

[0073] Obtained results: the conversion rate of nitric acid is 88%, the selectivity of nitrous acid is 2%, and the selectivity of methyl nitrite is 98...

Embodiment 3

[0075] The difference with Example 1 is: the particle diameter is 20-30 mesh 5g MoO 3 The catalyst and 5g of HZSM-5 catalyst with a particle size of 20-30 meshes were loaded into a glass tube reactor with a diameter of 15 mm, and the catalyst was reduced at 390° C. for 4 hours under a hydrogen atmosphere.

[0076] Then switch to a nitrogen atmosphere, add a reaction solution containing 2wt% nitric acid and 70wt% methanol to the fixed bed reactor with a metering pump, heat the upper section of the reactor to 80°C for dilute nitric acid reduction reaction, and heat the lower section of the reactor to 85°C for For the reaction of nitrite esterification, the weight hourly space velocity WHSV of the reaction solution is 2.0h -1 , Reduction and esterification reactions are carried out under a nitrogen atmosphere at atmospheric pressure.

[0077] Obtained results: the conversion rate of nitric acid is 96%, the selectivity of nitrous acid is 1%, and the selectivity of methyl nitrite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com