Adhesive for synthesizing polycrystalline cubic boron nitride material and using method of adhesive

A cubic boron nitride and polycrystalline cubic technology, which is used in the field of binders for the synthesis of polycrystalline cubic boron nitride materials, can solve the problems of poor high temperature thermal conductivity, difficult sintering and compaction, and reduced red hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take the molar ratio; Ti:Al:Cr:Nb=48:48:2:2, with intermetallic compound powder.

[0029] Prepare grinding balls and intermetallic compounds according to the ball mill mass ratio of 10:1; prepare cubic boron nitride powder according to the volume ratio of intermetallic compound powder: cubic boron nitride powder=20:80; the material of the grinding balls is stainless steel;

[0030] Add balls and intermetallic compounds into the ball mill for cold air ball milling; the speed of cold air ball milling is 300 rpm, the time is 20 hours, and the temperature of cold air is -30°C; then add the prepared cubic boron nitride powder; at 250 Rotation / min ball milling for 8 hours to obtain a uniformly mixed powder.

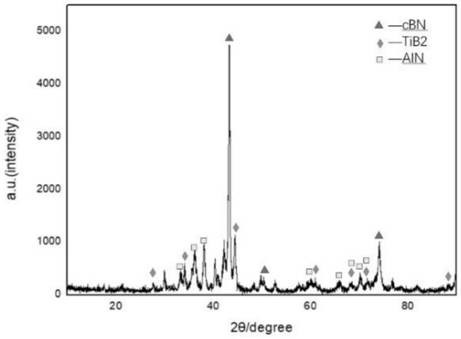

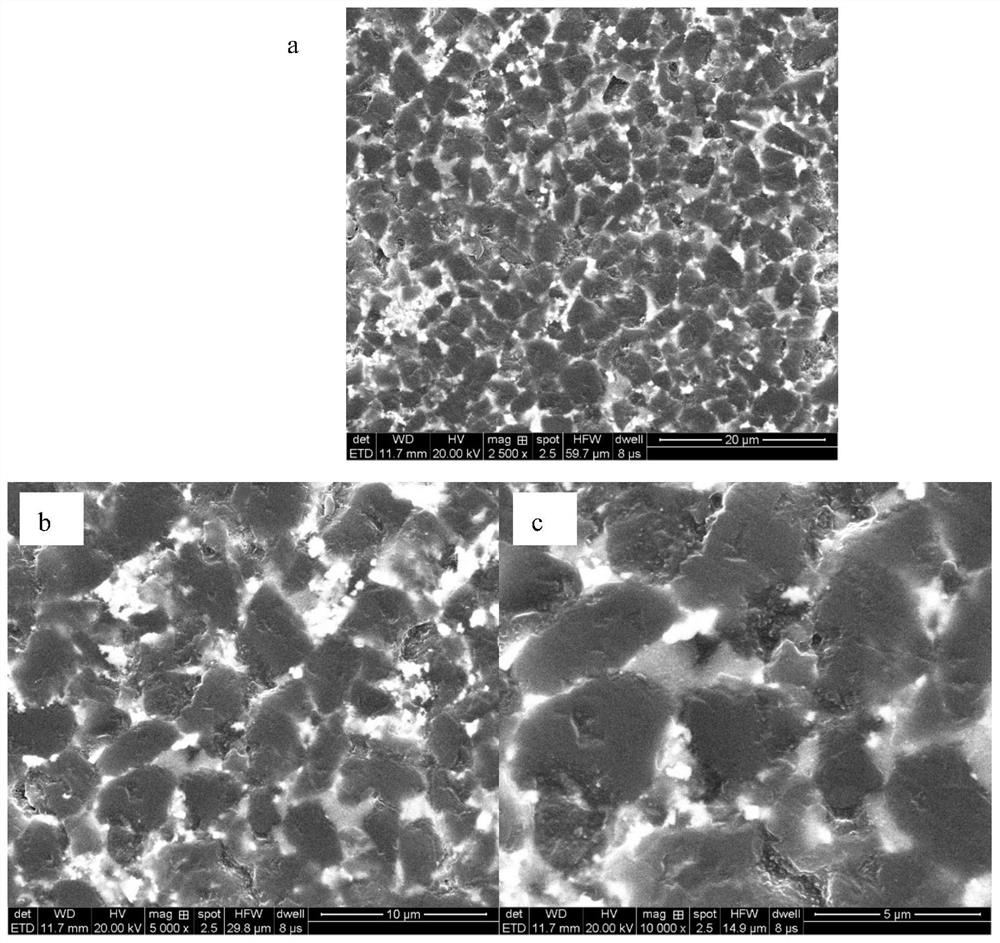

[0031] The uniformly mixed powder is first subjected to vacuum treatment below 1000Pa for 8 hours; after the vacuum treatment, it is sintered under high temperature and high pressure environment to obtain polycrystalline cubic boron nitride. The high temperature is 1190°...

Embodiment 2

[0038] Take the molar ratio; Ti:Al:Cr:Nb=43:48:2:7 to make intermetallic compound powder.

[0039] Prepare grinding balls and intermetallic compounds according to the ball mill mass ratio of 10:1; prepare cubic boron nitride powder according to the volume ratio of intermetallic compound powder: cubic boron nitride powder=20:80; the material of the grinding balls is stainless steel;

[0040] Add balls and intermetallic compounds into the ball mill for cold air ball milling; the speed of cold air ball milling is 300 rpm, the time is 20 hours, and the temperature of cold air is -30°C; then add the prepared cubic boron nitride powder; at 250 Rotation / min ball milling for 8 hours to obtain a uniformly mixed powder;

[0041] The uniformly mixed powder is first subjected to vacuum treatment below 1000Pa for 8 hours; after vacuum treatment, it is sintered under high temperature and high pressure environment to obtain polycrystalline cubic boron nitride. The high temperature is 1200°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com