Manufacturing method of bipolar polymer lithium ion battery and lithium ion battery

A lithium ion battery and a manufacturing method technology, which are applied in the field of bipolar polymer lithium ion battery manufacturing, can solve the problem of being difficult to meet the use requirements of long cycle life, avoid accelerated local aging, prolong cycle life, and improve internal performance. small resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the positive electrode active material sheet and the negative electrode active material sheet specifically includes: weighing the corresponding amount of the positive electrode material or the negative electrode material according to the weight ratio and putting it into the mixing tank; adding the conductive agent and performing initial mixing for 0.5h to 2h; adding the binder , stirring and mixing; after stirring for 1h to 3h, start the heating device of the mixing tank, and start dry mixing after heating to the set temperature; after the binder is completely fibrous, the positive active material or negative active material is obtained, and the The positive active material or the negative active material is pressed into a required size.

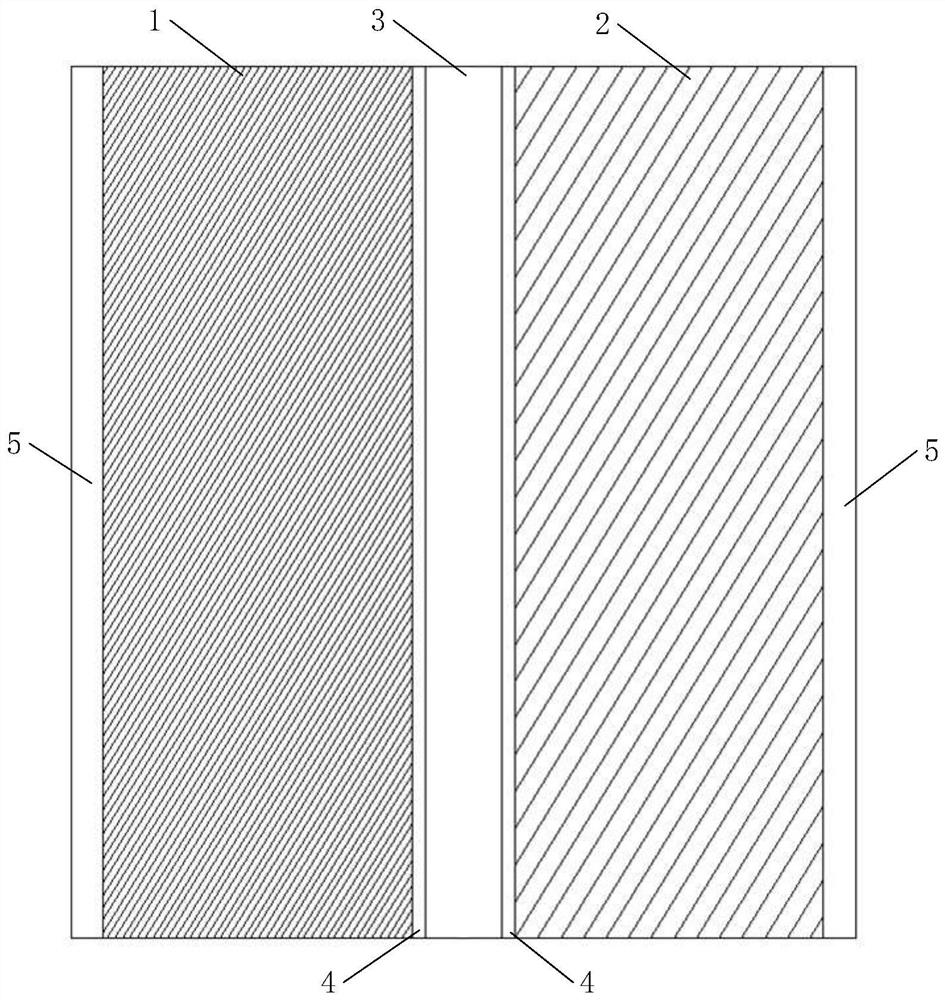

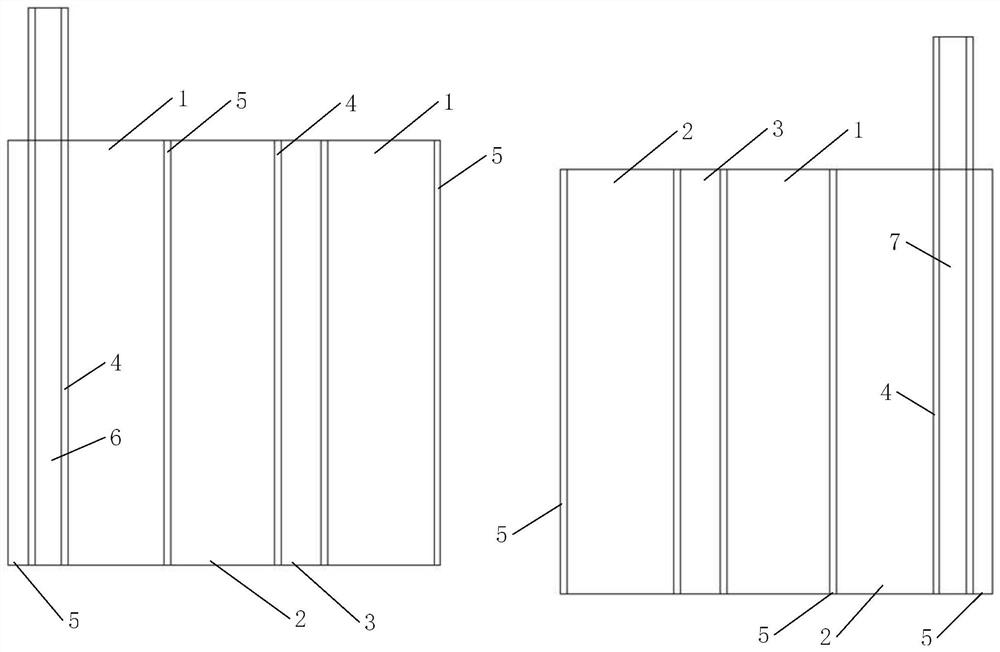

[0038] The two surfaces of the first current collector are respectively coated with a conductive layer and dried to obtain a bipolar pole piece substrate.

[0039] The positive electrode active material sheet...

Embodiment 1

[0058] An embodiment of the present invention provides a method for making a bipolar polymer lithium ion, comprising the following steps:

[0059] Weigh the corresponding weight of lithium iron phosphate according to the proportion of 92% by weight and put it into the mixing tank, add the composite conductive agent of 2.5% by weight of conductive carbon and 2.5% of carbon nanotubes, and perform initial mixing.

[0060] After 1 hour, 3% by weight of binder polytetrafluoroethylene was added, and stirring and mixing were continued.

[0061] After 2 hours, start the heating device of the mixing tank and stir, and continue to mix at a constant temperature of 345 ° C for 1.5 hours. After the binder polytetrafluoroethylene is completely fibrous, the positive active material is obtained, and the high-pressure calendering equipment is used to obtain the positive electrode active material. On the ethylene glycol substrate, the positive active material is pressed into a positive active m...

Embodiment 2

[0078] An embodiment of the present invention provides a method for making a bipolar polymer lithium ion, comprising the following steps:

[0079] Weigh the corresponding weight of lithium iron phosphate according to the proportion of 92% by weight and put it into the mixing tank, add the composite conductive agent of 2.5% by weight of conductive carbon and 2.5% of carbon nanotubes, and perform initial mixing.

[0080] After 1 hour, 3% by weight of binder polytetrafluoroethylene was added, and stirring and mixing were continued.

[0081] After 2 hours, start the heating device of the mixing tank and stir, and continue to mix at a constant temperature of 345 ° C for 1.5 hours. After the binder polytetrafluoroethylene is completely fibrous, the positive active material is obtained, and the high-pressure calendering equipment is used to obtain the positive electrode active material. On the ethylene glycol substrate, the positive active material is pressed into a positive active m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com