High-temperature-resistant long-service-life electrolyte for aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors with long life, which is applied in the direction of electrolytic capacitors, electrolytic capacitor manufacturing, capacitors, etc., and can solve the problems that the high temperature resistance performance of aluminum electrolytic capacitors needs to be improved, so as to overcome the shortened life, reduce the deterioration of oxide film, and reduce the possibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

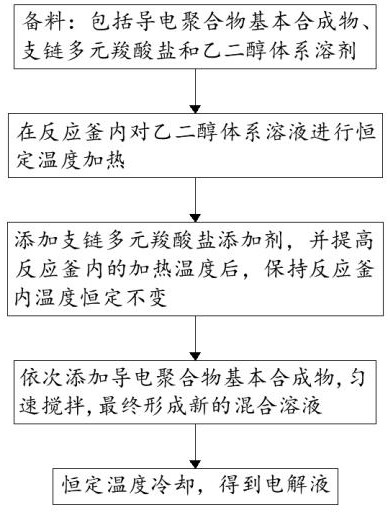

[0029] refer to figure 1 , an electrolytic solution for aluminum electrolytic capacitors with high temperature resistance and long service life, the preparation process of which comprises the following steps:

[0030] S01: Preparation of materials, including conductive polymer basic composition, branched polycarboxylate and ethylene glycol system solvent; solvent ethylene glycol 50g, additive A mannitol 5g, additive B phosphoric acid monoester 5g, solute ammonium azelate 10g , 20g of conductive polymer polythiophene, 2g of p-nitrophenol as hydrogen suppressor and 8g of hypophosphite as waterproof mixture;

[0031] S02: Heat the ethylene glycol system solution at a constant temperature in the reactor; keep the temperature range at 100°C;

[0032] S03: In step S02, add branched polycarboxylate additives, namely Additive A and Additive B, and increase the heating temperature in the reactor, keep the temperature in the reactor constant; the temperature range is kept at 120°C;

...

Embodiment 2

[0036] refer to figure 1 , an electrolytic solution for aluminum electrolytic capacitors with high temperature resistance and long service life, the preparation process of which comprises the following steps:

[0037] S01: Prepare materials, including conductive polymer basic composition, branched polycarboxylate and ethylene glycol system solvent; solvent δ-butyrolactone 60g, additive A8-hydroxyquinoline 5g, additive B ethylenediaminetetraacetic acid 5g, Solute 1.7-ammonium sebacate 10g, conductive polymer polyaniline 10g, hydrogen remover p-nitrobenzyl alcohol 2g and water-repellent mixture ammonium dihydrogen phosphate 8g;

[0038] S02: Heat the ethylene glycol system solution at a constant temperature in the reactor; keep the temperature range at 80°C;

[0039] S03: In step S02, add branched polycarboxylate additives, namely Additive A and Additive B, and increase the heating temperature in the reactor, keep the temperature in the reactor constant; the temperature range i...

Embodiment 3

[0043] refer to figure 1 , an electrolytic solution for aluminum electrolytic capacitors with high temperature resistance and long service life, the preparation process of which comprises the following steps:

[0044] S01: Preparation of materials, including conductive polymer basic composition, branched polycarboxylate and ethylene glycol system solvent; solvent ethylene glycol 65g, additive A polyvinylpyrrolidone 5g, additive B polyethylene glycol 5g, solute sebacic acid Ammonium 10g, conductive polymer polypyrrole 10g, dehydrogenation agent p-nitrobenzyl alcohol 1g and waterproof mixture agent ammonium dihydrogen phosphate 4g;

[0045] S02: Heat the ethylene glycol system solution at a constant temperature in the reactor; keep the temperature range at 85°C;

[0046] S03: Add branched polycarboxylate additives in step S02, that is, Additive A and Additive B, and after increasing the heating temperature in the reactor, keep the temperature in the reactor constant; the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com