Method for detecting inclusions in aluminum and aluminum alloy melt

A technology of aluminum alloy melt and detection method, which is applied in the preparation of test samples, material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the difficulty of aluminum sheet samples. Dissolution, time-consuming and other problems, to achieve the effect of speeding up the dissolution, ensuring the accuracy, and speeding up the dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

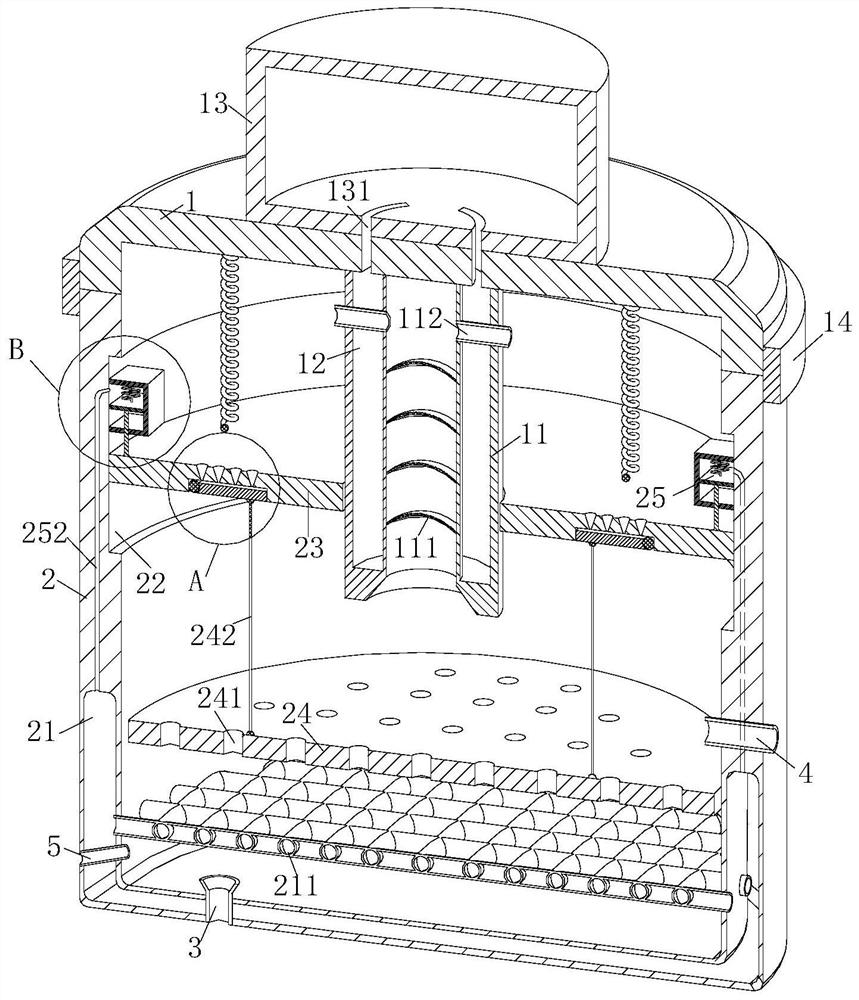

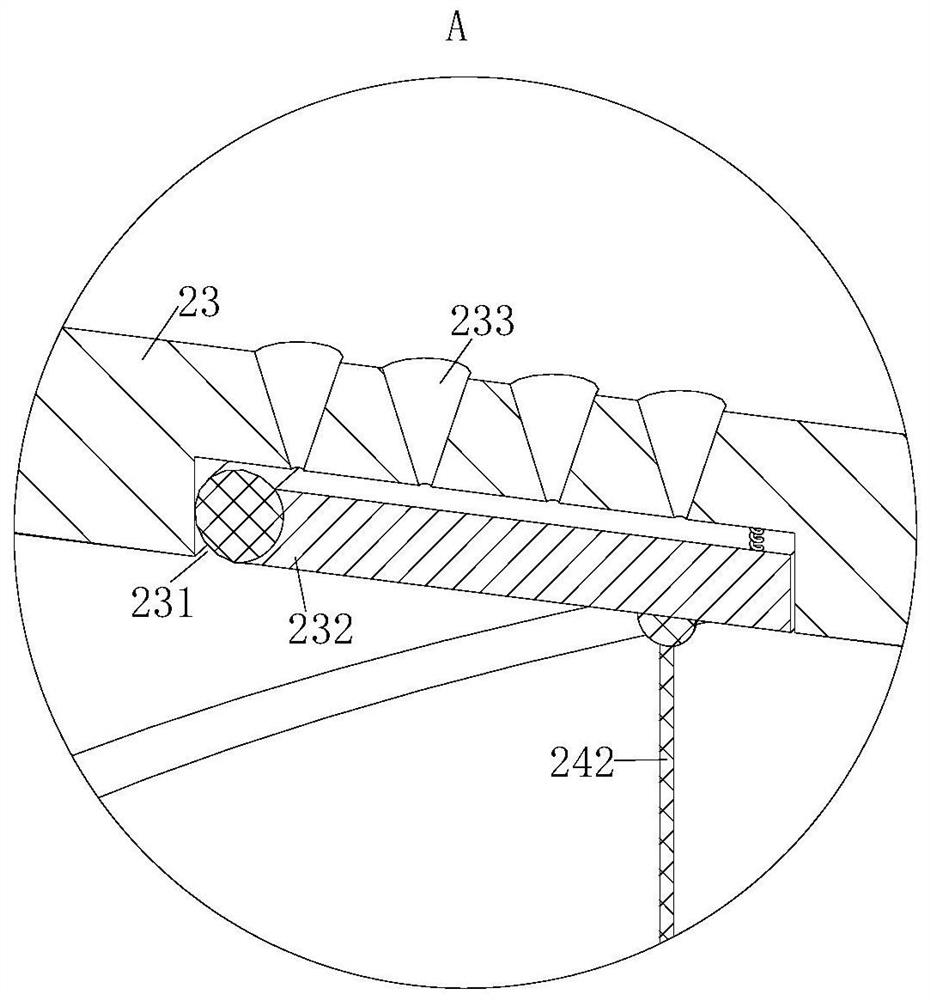

[0039] As a specific embodiment of the present invention, a No. 1 groove 231 is provided at the part where the lower surface of the partition plate 23 is connected to the No. 1 rope 242, and a No. 1 plate 232 is arranged inside the No. 1 slot 231. One end of the No. 1 plate 232 is It is rotatably connected with the inner surface of the side wall of the No. 1 groove 231, and the other end is connected with the upper bottom surface of the No. 1 groove 231 through a spring. The spring stiffness coefficient connected to the No. 1 plate 232 is relatively large; the top of the No. 1 slot 231 is provided with a No. 2 through hole 233, and the No. 2 through hole 233 is a tapered hole, and the No. 2 through hole 233 The larger end of the cross-section is located on the upper surface of the partition 23; the floating plate 24 drives the partition 23, so that the ethanol solution in the No. 1 area is added to the ethanol solution at the bottom of the cylinder body 2, which further promote...

Embodiment approach

[0041] As a specific embodiment of the present invention, the top of the cylinder cover 1 is provided with a condensate tank 13, and the inside of the condensate tank 13 is filled with cooling water; the condensate tank 13 communicates with the inside of the cooling chamber 12 through the No. Interconnected; through the effect of the condensed water tank 13, the cooling chamber 12 can better perform the condensation function to liquefy the ethanol gas and return to the effect, ensuring that the reaction can be carried out normally; when in use, when the cooling water in the cooling chamber 12 is mixed When the gas is heated and the temperature rises, the cooling water can exchange heat with the cooling water in the condensation tank through the No. 1 channel 131 to ensure that the cooling chamber 12 can function normally, so that the ethanol gas in the mixed gas can be condensed and liquefied in time And backflow to the bottom of cylinder body 2, it is ensured that the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com