High-chromium martensite cast iron heat treatment method based on natural aging

A heat treatment method and natural aging technology, applied in the field of high chromium cast iron, can solve the problems of high heat treatment process cost, complex heat treatment process and high heat treatment temperature, and achieve the effects of environmental friendliness, simple heat treatment method and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

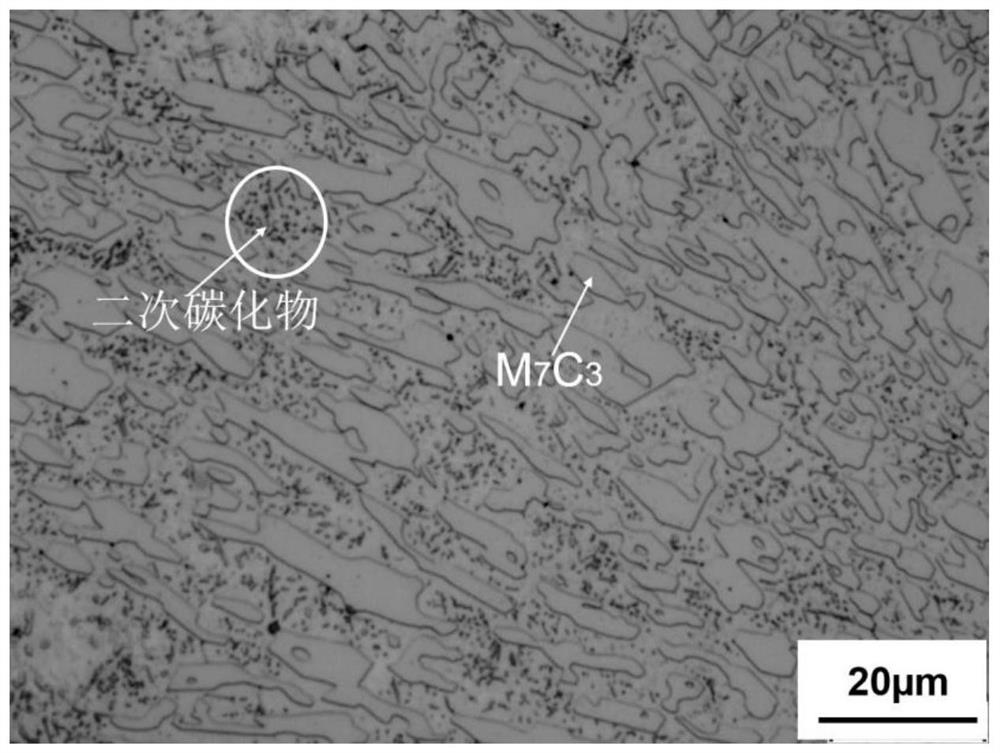

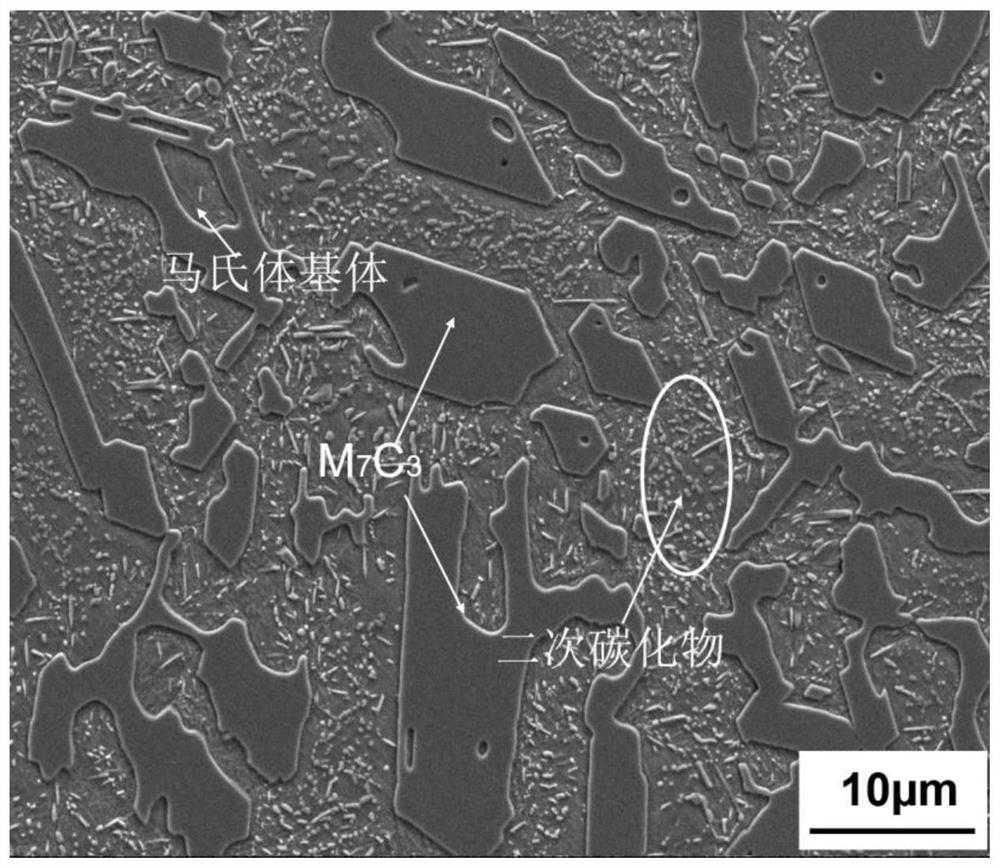

[0035] A heat treatment method for high chromium martensitic cast iron based on natural aging. The chemical composition and mass percentage of the high chromium martensitic cast iron are: C is 2.8%, Cr is 18.2%, Si is 0.5%, Mn is 2.0%, Cu is 0.7%, P≤0.49%, S≤ 0.49%, wherein Cr / C=18.2 / 2.8=6.5, and the balance is Fe. Batching, smelting, pouring and grinding according to the above chemical composition and its mass percentage content, after grinding, heat preservation at 900°C for 1 hour, then water quenching to room temperature, and natural aging at room temperature for 7 days to obtain high chromium horse Tensitic cast iron. The matrix structure of the high chromium martensitic cast iron is martensite.

[0036] The high chromium martensitic cast iron obtained in the two stages of the heat treatment of this embodiment is detected respectively: the hardness of the high chromium martensitic cast iron before natural aging is 61.4HRC, and the V-notch impact energy is 2.0J; the high c...

Embodiment 2

[0038] A heat treatment method for high chromium martensitic cast iron based on natural aging. The chemical composition and mass percentage of the high chromium martensitic cast iron are: C is 2.5%, Cr is 18%, Si is 0.6%, Mn is 2.3%, Cu is 0.8%, P≤0.05%, S≤ 0.05%, where Cr / C=18 / 2.5=7.2, and the balance is Fe. Batching, smelting, pouring and grinding according to the above chemical composition and its mass percentage content, after grinding, heat preservation at 950°C for 1 hour, then water quenching to room temperature, and natural aging at room temperature for 15 days to obtain high chromium horse Tensitic cast iron. The matrix structure of the high chromium martensitic cast iron is martensite.

[0039] The high-chromium martensitic cast irons obtained in the two stages of heat treatment in this embodiment were detected respectively: the hardness of the high-chromium martensitic cast irons before natural aging was 62.5HRC, and the V-notch impact energy was 1.8J; the high-ch...

Embodiment 3

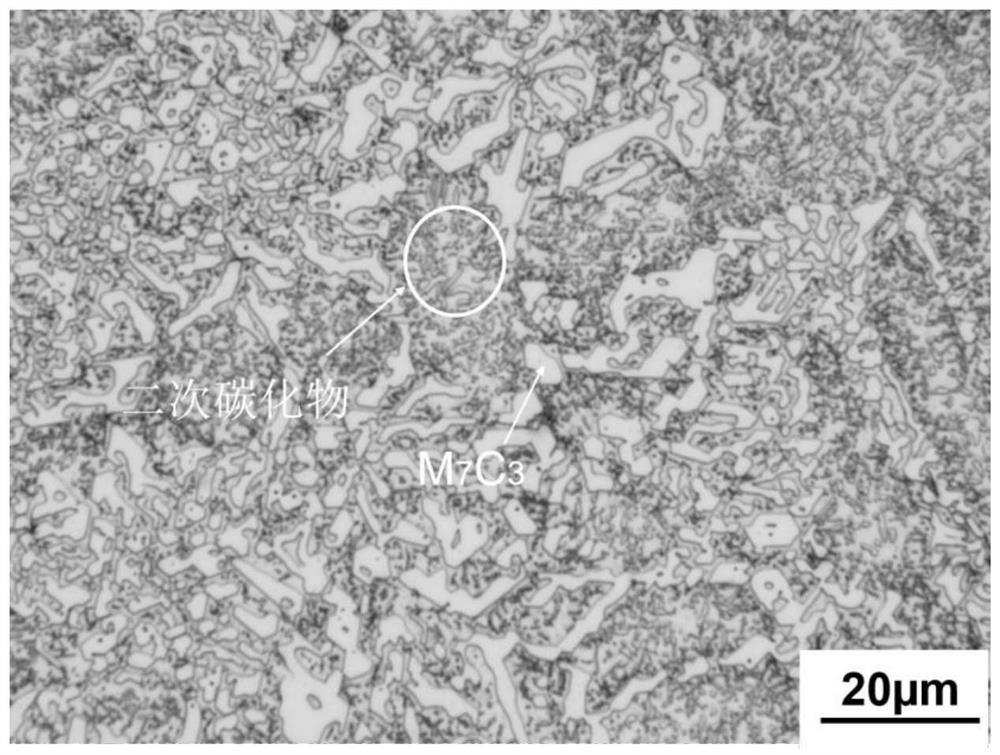

[0041] A heat treatment method for high chromium martensitic cast iron based on natural aging. The mass percentages of the chemical components of the high chromium martensitic cast iron are: C is 2.9%, Cr is 20%, Si is 0.9%, Mn is 2.5%, Cu is 1.0%, P≤0.05%, S≤0.05 %, where Cr / C=20 / 2.9=6.9, and the balance is Fe. Batching, smelting, pouring and grinding according to chemical composition and mass percentage; after grinding, heat preservation at 950°C for 1.5 hours, and natural aging at room temperature for 18 days to obtain high-chromium martensitic cast iron. The matrix structure of the high chromium martensitic cast iron is martensite.

[0042] The high chromium martensitic cast irons obtained in the two stages of heat treatment in this embodiment were detected respectively: the hardness of the high chromium martensitic cast irons before natural aging was 61.9HRC, and the V-notch impact energy was 1.7J; the high chromium martensitic cast irons after natural aging The hardnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com