Magnesia carbon brick for vicinity of furnace door of electric arc furnace and preparation method of magnesia carbon brick

A magnesia-carbon brick and furnace door technology, applied in the field of magnesia-carbon brick processing, can solve the problems of poor performance of magnesia-carbon bricks, hidden dangers, and difficulty in gunning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

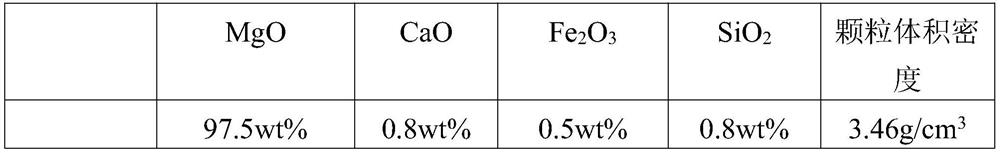

[0040] A magnesia-carbon brick used near the door of an electric furnace consists of the following raw materials in parts by weight:

[0041] 20 parts of fused magnesia with 3mm≤particle size<5mm,

[0042] 25 parts of fused magnesia with 1mm≤particle size<3mm,

[0043] 20 parts of fused magnesia with 0.1mm≤particle size<1mm,

[0044] 16 parts of fused magnesia fine powder with particle size less than 0.088mm,

[0045] 12 parts of flake graphite with a particle size of 0.05mm,

[0046] 3 parts of phenolic resin binder,

[0047] The additive is 3 parts, and the additive is composed of titanium carbonitride, metal aluminum powder and carbon fiber with a mass ratio of 1:2:1, wherein the particle diameters of titanium carbonitride, metal aluminum powder and carbon fiber are all 325 mesh.

[0048] The magnesia carbon brick used near the electric furnace door is prepared by the following steps:

[0049] 1) Ingredients: Dry mix the additives evenly in the vibrating mill to make c...

Embodiment 2

[0056] A magnesia-carbon brick used near the door of an electric furnace consists of the following raw materials in parts by weight:

[0057] 22 parts of fused magnesia with 3mm≤particle size<5mm,

[0058] 30 parts of fused magnesia with 1mm≤particle size<3mm,

[0059] 18 parts of fused magnesia with 0.1mm≤particle size<1mm,

[0060] 16 parts of fused magnesia fine powder with particle size less than 0.088mm,

[0061] 14 parts of flaky graphite with a particle size of 0.05 mm,

[0062] 5 parts of additives, the additives are composed of titanium carbonitride, metal aluminum powder and carbon fiber with a mass ratio of 2:2:1, wherein the particle diameters of titanium carbonitride, metal aluminum powder and carbon fiber are all 325 mesh.

[0063] 2.5 parts of phenolic resin binder,

[0064] The magnesia carbon brick used near the electric furnace door is prepared by the following steps:

[0065] 1) Ingredients: Dry mix the additives evenly in the vibrating mill to make co-...

Embodiment 3

[0072] A magnesia-carbon brick used near the door of an electric furnace consists of the following raw materials in parts by weight:

[0073] 23 parts of fused magnesia with 3mm≤particle size<5mm,

[0074] 29 parts of fused magnesia with 1mm≤particle size<3mm,

[0075] 19 parts of fused magnesia with 0.1mm≤particle size<1mm,

[0076] 14 parts of fused magnesia fine powder with particle size less than 0.088mm,

[0077] 14 parts of flaky graphite with a particle size of 0.05 mm,

[0078] 6 parts of additive agent, the additive is composed of titanium carbonitride, metal aluminum powder and carbon fiber with a mass ratio of 2:2:2, wherein the particle diameters of titanium carbonitride, metal aluminum powder and carbon fiber are all 325 mesh.

[0079] 2.5 parts of phenolic resin binder,

[0080] The magnesia carbon brick used near the electric furnace door is prepared by the following steps:

[0081] 1) Ingredients: Dry mix the additives evenly in the vibrating mill to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com