High Load Heat Resistant Composite Cable

A composite cable, high-load technology, applied in the direction of communication cables, insulated cables, cables, etc., can solve the problems of affecting signal transmission and damage, and achieve the effects of improving thermal shrinkage, prolonging service life, and reducing thermal shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

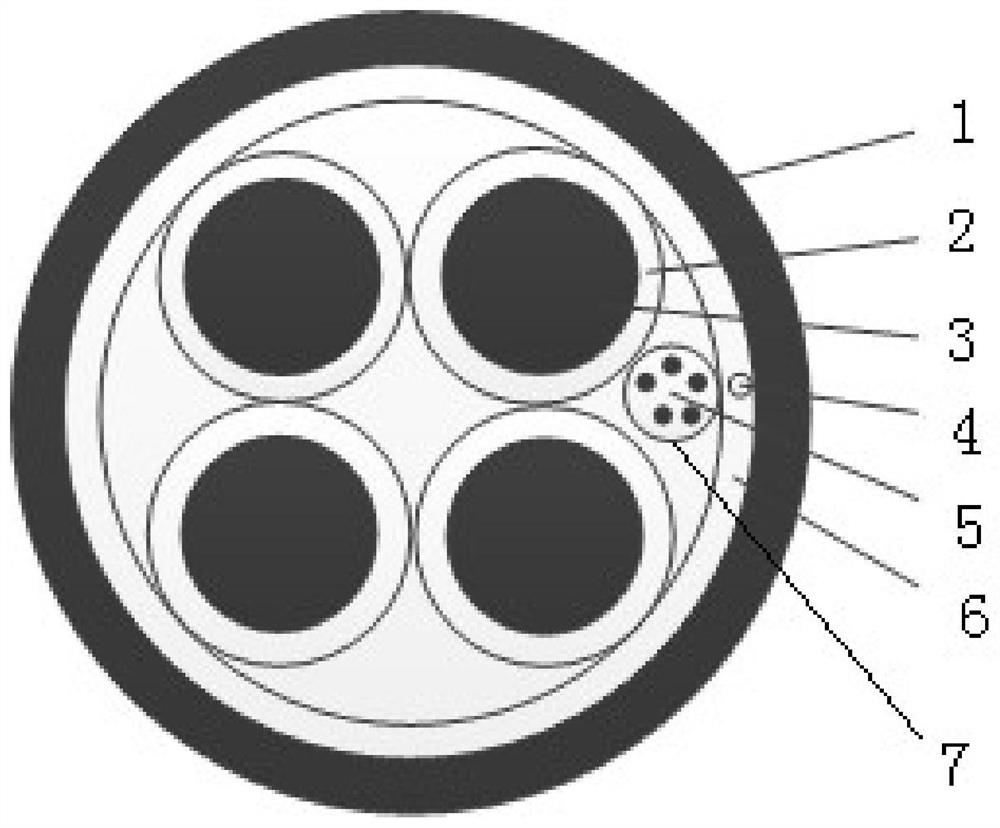

[0032] Embodiments 1 to 4: A high-load heat-resistant composite cable, including several conductors 3 and optical units 5, the conductors 3 and optical units 5 are twisted together, and the outside of the conductors 3 and optical units 5 is provided with a tape 6, so A tearing rope 4 is embedded in the tape 6, an outer sheath 1 is provided on the outside of the tape 6, an insulating sheath 2 is provided on the outside of the conductor 3, and an optical unit sheath is provided on the outside of the optical unit 5 7;

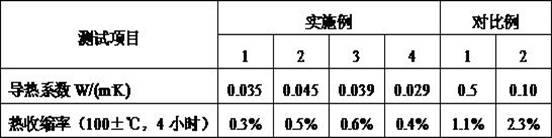

[0033] The optical unit sheath 7 of the above-mentioned embodiments 1-4 is composed of the following components, as shown in Table 1:

[0034] Table 1

[0035] components Example 1 Example 2 Example 3 Example 4 Ethylene-vinyl acetate copolymer 72 65 60 80 Linear Low Density Polyethylene 16 10 15 18 EPDM 12 20 10 16 Vinyltriethoxysilane 1 2.5 1.8 2 Didodecyl Thiodipropionate 1.5 2 1 1.6 Silicone m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com