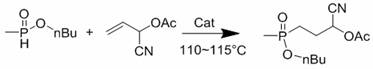

Method for synthesizing 3-(butoxy methyl phosphoryl)-1-cyanopropyl acetate based on micro-channel reactor

A cyanopropyl acetate and micro-channel reactor technology is applied in the field of glufosinate-ammonium intermediate synthesis, and can solve the problems of difficult control, high safety risk, low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for synthesizing 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate based on a microchannel reactor, comprising the following steps:

[0028] A. Turn on the heating system and light system (light wavelength 10nm) of the microchannel reactor to raise the temperature of the system to a reaction temperature of 30°C;

[0029] B. Metering monobutyl methylphosphinate and 1-cyano-2-propenyl acetate into the microchannel reactor (wherein, monobutyl methylphosphinate 3mol / min, 1-cyano- 2-propenyl acetate 1mol / min), the reaction pressure is normal pressure;

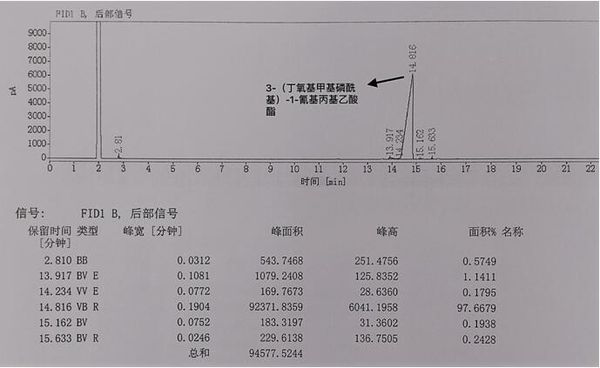

[0030] C. The two materials introduced in step B stay and react in the microchannel reactor for 0.5min. After the temperature reaches 120°C under 10mmHg pressure and stop distillation to remove low boilers, 3-(butoxymethylphosphoryl )-1-cyanopropyl acetate target product 3939.1g, gas chromatography detection 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate content 96.9%, yield 97.4%.

Embodiment 2

[0032] A method for synthesizing 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate based on a microchannel reactor, comprising the following steps:

[0033] A. Turn on the heating system and light system (light wavelength 700nm) of the microchannel reactor to raise the temperature of the system to a reaction temperature of 70°C;

[0034] B. Metering monobutyl methylphosphinate and 1-cyano-2-propenyl acetate into the microchannel reactor (wherein, monobutyl methylphosphinate 2mol / min, 1-cyano- 2-propenyl acetate 1mol / min), the reaction pressure is 1.8MPa;

[0035] C. The two materials introduced in step B stay and react in the microchannel reactor for 5 minutes. After the temperature reaches 125°C under the pressure of 10mmHg, the distillation is stopped to remove low boilers, and 3-(butoxymethylphosphoryl) is obtained. - 1-cyanopropyl acetate The target product was 3939g, the content of 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate was 97.6% as detected by gas chromatograph...

Embodiment 3

[0037] A method for synthesizing 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate based on a microchannel reactor, comprising the following steps:

[0038] A. Turn on the heating system and illumination system (light wavelength 100nm) of the microchannel reactor to heat up the system to a reaction temperature of 50°C;

[0039] B. Metering monobutyl methylphosphinate and 1-cyano-2-propenyl acetate into the microchannel reactor (wherein, monobutyl methylphosphinate 1.5mol / min, 1-cyano -2-propenyl acetate 1mol / min), the reaction pressure is 1MPa;

[0040] C. The two materials introduced in step B stay and react in the microchannel reactor for 2 minutes. After the temperature reaches 121°C under 10mmHg pressure and stop distillation to remove low boilers, 3-(butoxymethylphosphoryl) is obtained. - 1-cyanopropyl acetate The target product was 3937.9g, the content of 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate was 97.3% as detected by gas chromatography, and the yield was 97.4%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com