Ether type polycarboxylic acid slump retaining agent and preparation method thereof

A technology of ether polycarboxylic acid and slump retention agent, which is applied in the field of building material admixtures, can solve the problems of poor water reduction rate and slump retention, and achieves reduction of carboxyl group density, production cost reduction, and short reaction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

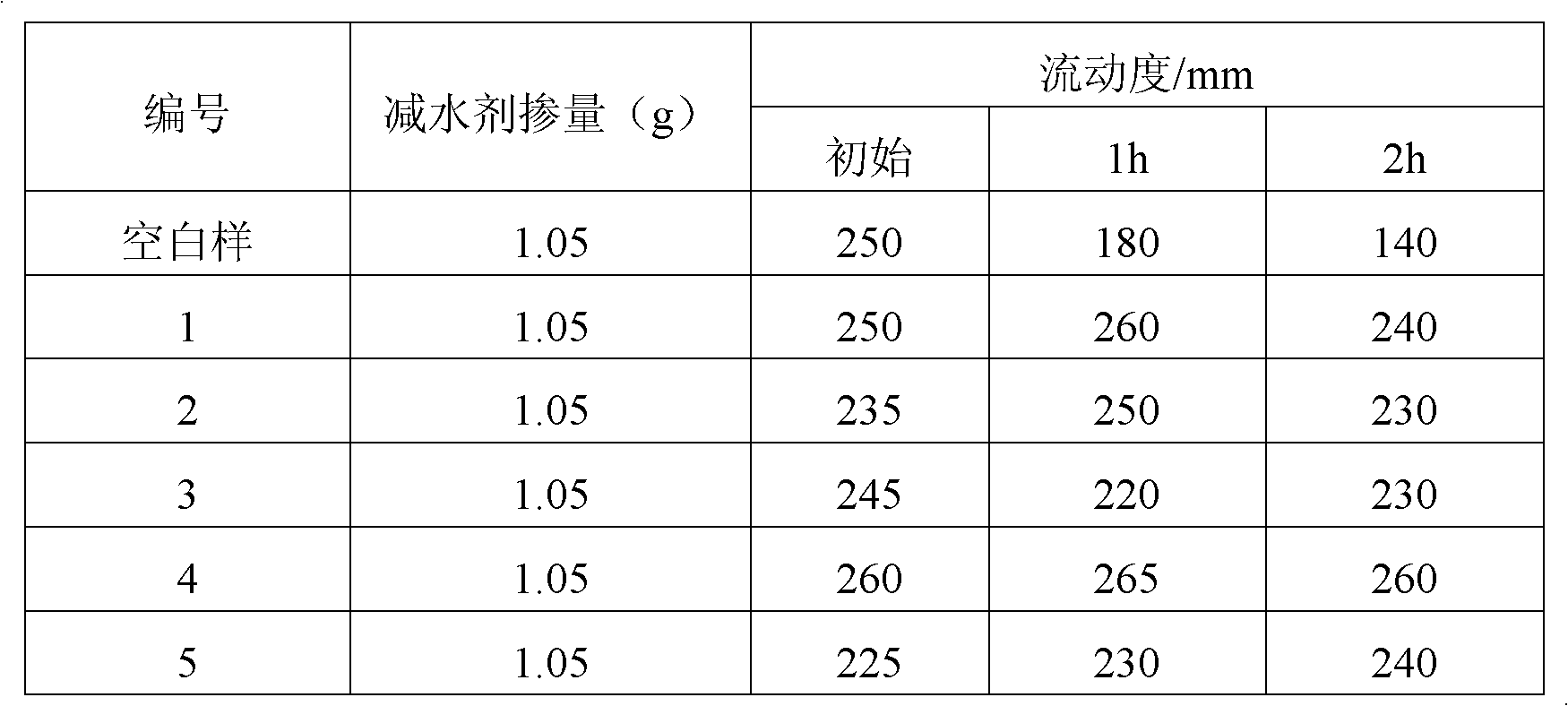

Examples

Embodiment 1

[0031] First add 120.0g methyl propyl polyoxyethylene ether, 6.0g sodium p-styrene sulfonate and 116.5g deionized water into the three-necked flask, stir until the materials are completely dissolved to a transparent state, add 2.0g hydrogen peroxide and continue stirring for 5-10 After 10 minutes, start to add solution A and solution B evenly, wherein solution A consists of 40.0g acrylic acid, 30.0g acrylate-β-hydroxypropyl and 40.5g deionized water; solution B consists of 1.0g sodium sulfite, 1.0g dodecane base mercaptan and 18g deionized water. The temperature was controlled at 40°C, and the dripping of solution A was completed in 3 hours, and the solution of B was dripped in 3.5 hours. After the B solution was dripped, continue to stir for 1h to ripen. Add 74.0 g of 30% liquid caustic soda, adjust the pH value to about 7, and adjust the concentration to 40% with deionized water to obtain the finished product. For its infrared spectrum, see figure 1 , see gel chromatogram...

Embodiment 2

[0033] First add 160.0g of methyl propyl polyoxyethylene ether, 6.0g of sodium p-styrene sulfonate and 113.0g of deionized water into the three-necked flask, stir until the materials are completely dissolved to a transparent state, then add 1.0g of hydrogen peroxide and continue stirring for 5-10 After 10 minutes, start to drop first solution and second solution evenly, wherein first solution is made up of 10.0g acrylic acid, 20.0g 2-hydroxy-2-butyl acrylate and 16.5g deionized water; second solution is made up of 2.0g sodium hypophosphite, 1.0g of 3-mercaptopropionic acid and 18g of deionized water. The temperature was controlled at 40°C, and the dripping of solution A was completed in 3 hours, and the solution of B was dripped in 3.5 hours. After the B solution was dripped, continue to stir for 1h to ripen. Add 18.5g of 30% liquid caustic soda, adjust the pH value to about 7, and adjust the concentration to 40% with deionized water to obtain the finished product.

Embodiment 3

[0035] First add 150.0g of methyl propyl polyoxyethylene ether, 16.0g of sodium p-styrene sulfonate and 110.0g of deionized water into the three-necked flask, stir until the materials are completely dissolved to a transparent state, then add 2.0g of hydrogen peroxide and continue stirring for 5-10 After 10 minutes, start to add solution A and solution B evenly, wherein solution A consists of 20.0g acrylic acid, 10.0g ethyl acrylate and 30.0g deionized water; solution B consists of 1.0g L-ascorbic acid, 1.0g 3-mercaptoacetic acid and 18g deionized water composition. The temperature is controlled at 50°C, and the solution of A is controlled to be dripped in 3 hours, and the solution of B is dripped in 4.5 hours. After the B solution was dripped, continue to stir for 1h to ripen. Add 37.0 g of 30% liquid caustic soda, adjust the pH value to about 7, and adjust the concentration to 40% with deionized water to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com