CZT film composite material with composite passivation layer, nuclear radiation detection device and preparation method thereof

A composite material and passivation layer technology, applied in semiconductor devices, electrical components, final product manufacturing, etc., can solve problems such as difficulty in meeting large-area detectors, difficulty in CZT single crystals, and long growth cycles, and achieve improved electrical performance, The effect of reducing surface leakage current and small leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

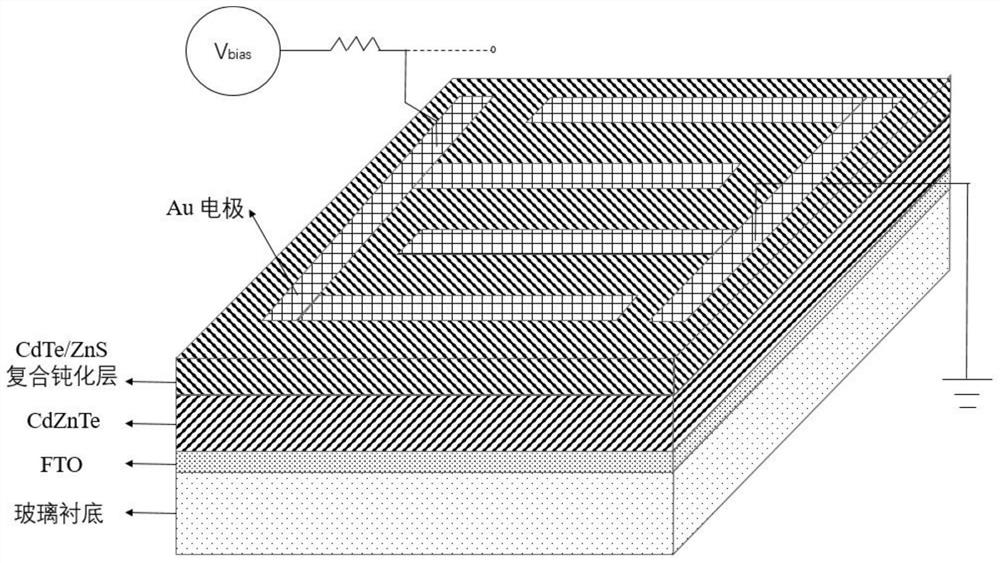

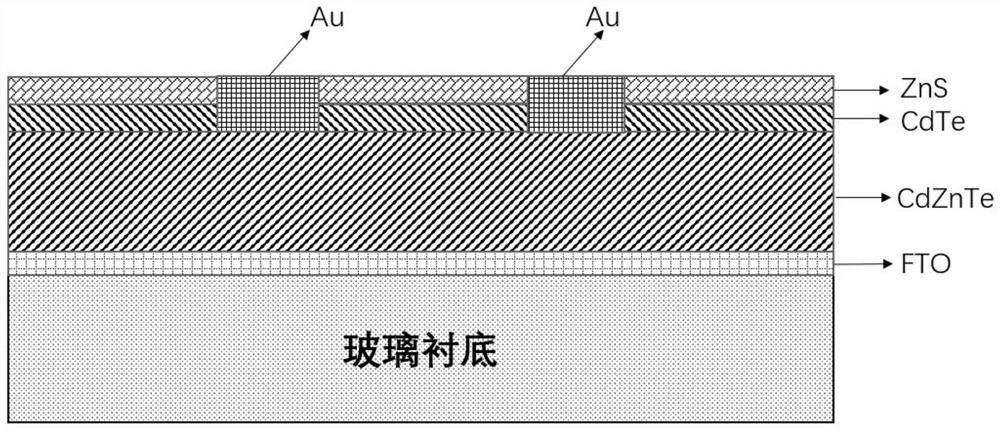

[0037] In this example, see figure 1 and figure 2, a cadmium zinc telluride film composite material with a composite passivation layer, the structure of the composite CZT film in the form of a sandwich structure of the substrate-semiconductor-composite passivation layer is adopted, and the substrate, the CZT film, and the composite passivation layer are sequentially formed. The three parts of the layer are stacked and deposited; the high-purity CZT polycrystalline material with a purity of not less than 99% is selected as the raw material for near-space sublimation, and the CZT film is prepared on the substrate by the near-space sublimation method, and then the CZT film is polished and After corrosion, the composite passivation layer of cadmium telluride and zinc sulfide is continuously grown on the CZT film by radio frequency magnetron sputtering deposition method, and the composite material of cadmium zinc telluride film with the composite passivation layer is obtained. se...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, especially in that:

[0056] In this example, see figure 1 and figure 2 , a cadmium zinc telluride film composite material with a composite passivation layer, the structure of the composite CZT film in the form of a sandwich structure of the substrate-semiconductor-composite passivation layer is adopted, and the substrate, the CZT film, and the composite passivation layer are sequentially formed. The three parts of the layer are stacked and deposited; the high-purity CZT polycrystalline material with a purity of not less than 99% is selected as the raw material for near-space sublimation, and the CZT film is prepared on the substrate by the near-space sublimation method, and then the CZT film is polished and After corrosion, the composite passivation layer of cadmium telluride and zinc sulfide is continuously grown on the CZT film by radio frequency magnetron sputtering deposition method, and the composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com