Boiler energy saving and flue gas white smoke removal system, process and application

A flue gas and boiler technology, which is applied in the process and application field of boiler energy saving and flue gas dewhitening system, can solve the problem of low temperature corrosion of rotary air preheater, affecting flue gas dewhitening effect, and high operation and maintenance cost. problems, to ensure long-term safe, stable and economical operation, no risk of failure and shutdown, and the effect of adapting to changes in boiler load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

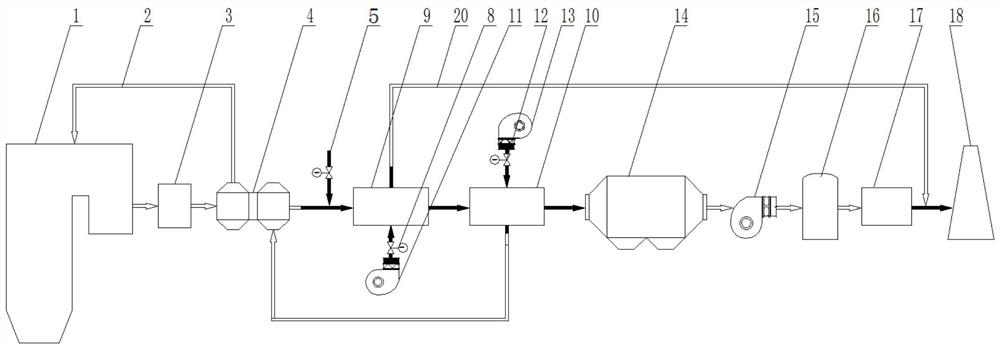

[0031] A boiler energy saving and flue gas dewhitening system, such as figure 1 As shown, it includes boiler 1, denitrification device 3, rotary air preheater 4, mixed air heater 9, flue gas heater 10, electrostatic precipitator 14, desulfurization tower 16 and chimney 18, which are connected in sequence. The air outlet of the blower 10 is connected to the air inlet of the rotary air preheater 4 through the warm air pipe 19, the air outlet of the rotary air preheater 4 is connected to the boiler 1 through the hot air pipe 2, and the air outlet of the mixed air heater 9 passes through The air mixing pipe 20 connects the flue between the desulfurization tower 16 and the chimney 18 . For a coal-fired boiler system of a single 1000MW power plant, the depth (flue flow direction) from the outlet of the rotary air preheater to the inlet of the electrostatic precipitator is about 32 meters, the width direction is about 89.410 meters, and the elevation of the center of the inlet of the...

Embodiment 2

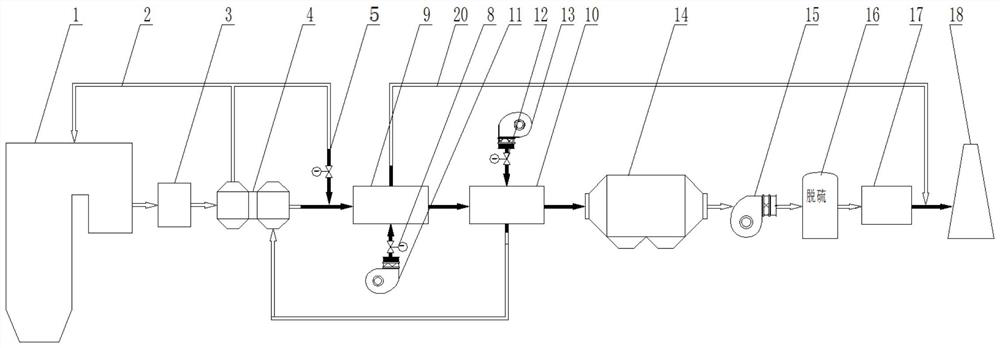

[0043] A boiler energy saving and flue gas dewhitening system, combined with reference to Example 1 figure 2 As shown, the difference between it and Embodiment 1 is that the flue from the outlet of the rotary air preheater 4 to the inlet of the electrostatic precipitator 14 is divided into 10 groups of independent flue gas passages, and the flue gas inlet side of each mixed air heater 9 A high-temperature air interface (namely, the medium interface 5) is provided, and the high-temperature air interface is connected to the hot air pipe 2. When in use, hot air with a temperature higher than 207°C introduced into the hot air pipe 2 is used as the dry burning medium in the dry burning flue. Of course, the flue from the outlet of the rotary air preheater 4 to the inlet of the electrostatic precipitator 14 can also be divided into multiple groups (such as 12 groups, 15 groups, 25 groups, etc.) of independent flue gas passages as required. In this embodiment, by introducing hot air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com