Flexible electroluminescent device capable of dynamically changing color and preparation method thereof

A technology of luminescence and flexible electricity, applied in the field of flexible electroluminescent devices and their preparation, to achieve the effect of excellent flexibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

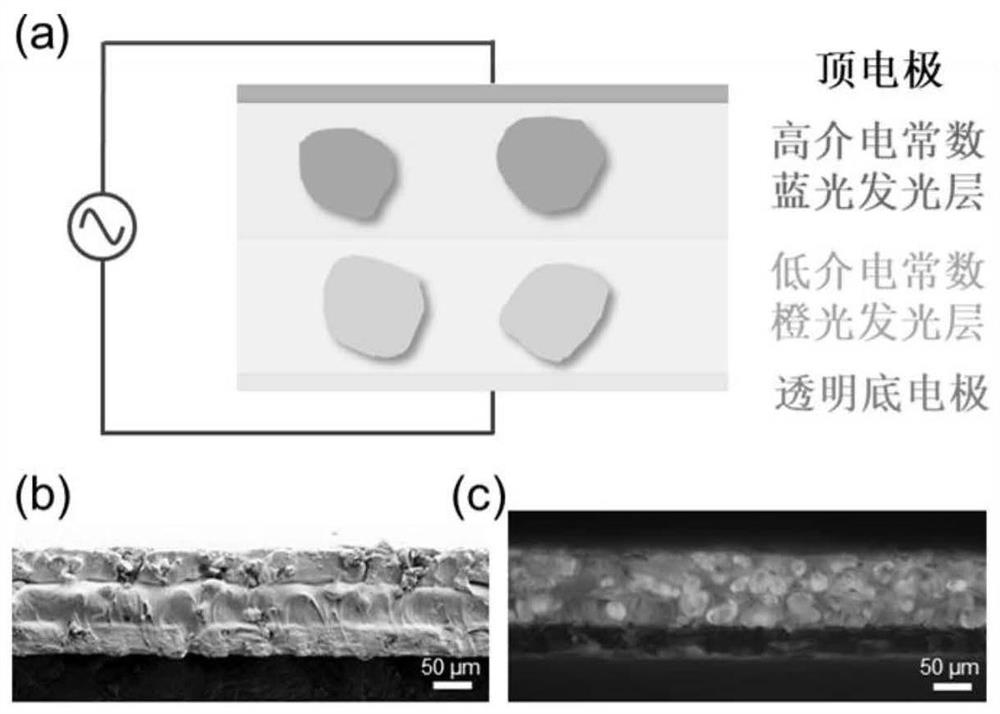

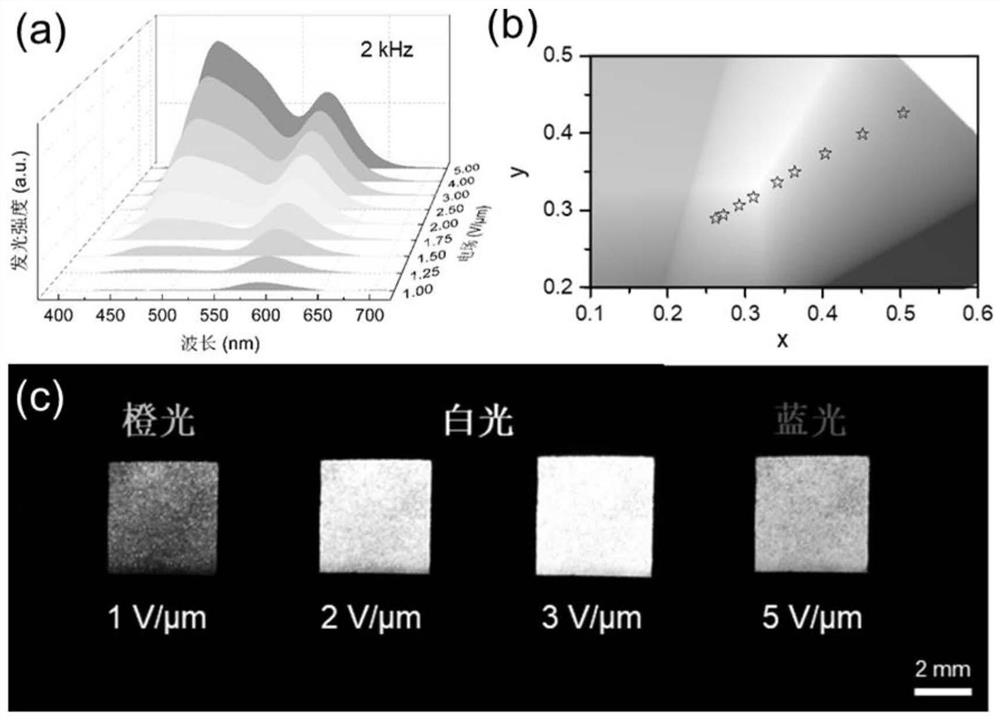

[0025] (1) Preparation of luminescent active components: Take 2 grams of manganese-doped zinc sulfide electroluminescent powder, add it to 10 grams of 20% solid content of styrene-butadiene-styrene thermoplastic elastomer / toluene solution, stir Mix evenly to obtain orange luminescent powder / polymer composite active material with low dielectric constant; get 2 grams of copper-doped zinc sulfide electroluminescent powder, add it to 10 grams of solid content in 20% cyano resin solution, stir Mix evenly to obtain blue light-emitting powder / polymer composite active material with high dielectric constant;

[0026] (2) Preparation of light-emitting layer: Spin-coat the orange light-emitting powder / polymer composite active material prepared in step (1) onto a flexible indium tin oxide / polyethylene terephthalate substrate through solution to obtain orange The light-emitting layer is dried on a hot stage at 80°C for 5 minutes, and then the blue light-emitting powder / polymer composite ac...

Embodiment 2

[0029] (1) Preparation of luminescent active components: Take 2 grams of manganese-doped zinc sulfide electroluminescent powder, add it to 10 grams of 20% solid content of styrene-butadiene-styrene thermoplastic elastomer / toluene solution, stir Mix evenly to obtain low dielectric constant orange luminescent powder / polymer composite active material; take 2 grams of copper-doped zinc sulfide electroluminescent powder, add it to 10 grams of solid content of 20% polyurethane solution, stir and mix evenly , to obtain blue light-emitting powder / polymer composite active material with high dielectric constant;

[0030] (2) Preparation of light-emitting layer: Spin-coat the orange light-emitting powder / polymer composite active material prepared in step (1) onto a flexible indium tin oxide / polyethylene terephthalate substrate through solution to obtain orange The light-emitting layer is dried on a hot stage at 80°C for 5 minutes, and then the blue light-emitting powder / polymer composite...

Embodiment 3

[0033] (1) Preparation of luminescent active components: Take 2 grams of manganese-doped zinc sulfide electroluminescent powder, add it to 10 grams of 20% solid content of styrene-butadiene-styrene thermoplastic elastomer / toluene solution, stir Mix evenly to obtain orange luminescent powder / polymer composite active material with low dielectric constant; get 2 grams of copper-doped zinc sulfide electroluminescent powder, add it to 10 grams of solid content in 20% cyano resin solution, stir Mix evenly to obtain blue light-emitting powder / polymer composite active material with high dielectric constant;

[0034] (2) Preparation of luminescent layer: Scrape-coat the orange luminescent powder / polymer composite active material prepared in step (1) on the silver nanowire / polyurethane substrate through the solution to obtain an orange luminescent layer, and put it in a solvent such as room temperature After natural volatilization, scrape-coat the blue light-emitting powder / polymer comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com