A kind of preparation method of thick-gauge copper-steel composite board

A composite board and thick-gauge technology, which is applied in the field of manufacturing thick-gauge copper-steel composite boards, can solve problems such as large plastic deformation of composite boards, large residual stress at the interface, and complicated production process, so as to eliminate stress and improve interface bonding Quality, service life improvement and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

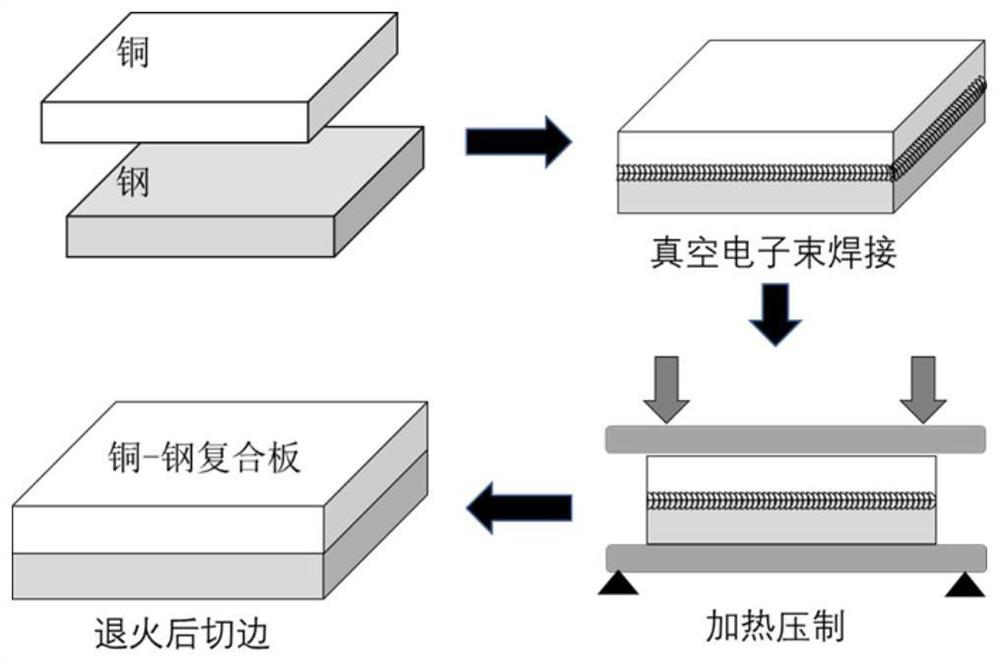

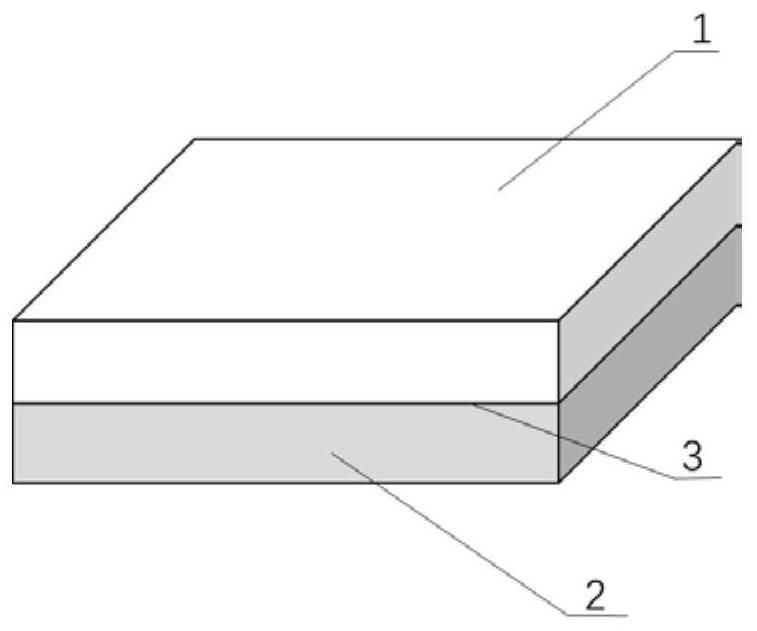

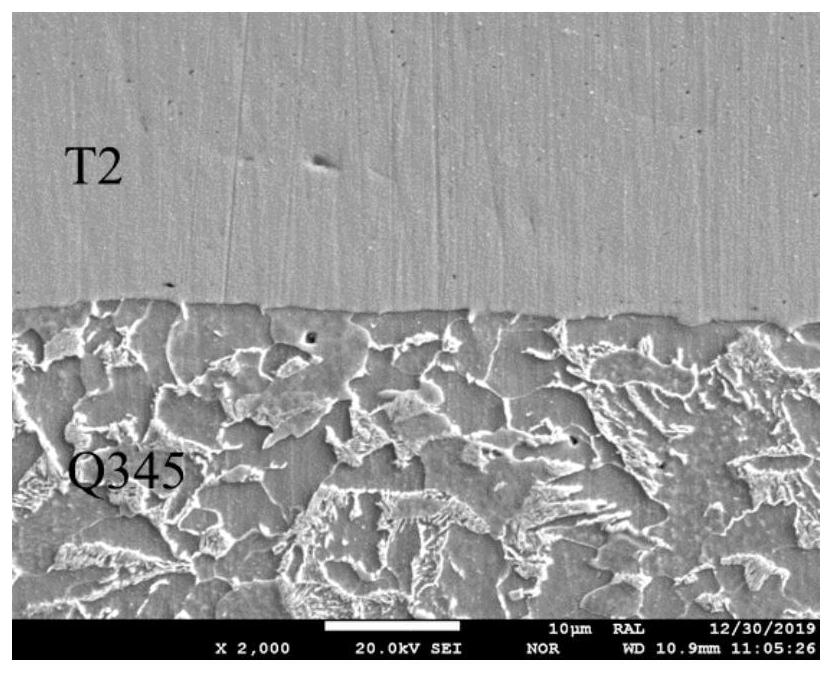

[0028] A preparation method of a thick gauge copper-steel clad plate, the specific operation steps are:

[0029] Step 1: Use a belt sander to grind the surfaces to be joined and the sides of the copper plate and the steel plate, respectively, to make the polished surface metallic luster, and then use alcohol and acetone to clean the polished surfaces in turn; T2 copper plate and Q345 steel plate are used as the base material of copper-steel composite plate. The specification of T2 copper plate is 200mm×400mm×20mm, and the specification of Q345 steel plate is 200mm×400mm×30mm; the surface roughness Ra≤100μm;

[0030] Step 2: Assemble the treated copper plates and steel plates, then stack them into the working chamber of the vacuum electron beam welding machine, and vacuumize them to 1×10 -2 Pa, and then adopt the welding process of welding speed of 200mm / min and welding electron beam current of 55mA to vacuum-weld and encapsulate the plate; during welding, the position of the b...

Embodiment 2

[0036] A preparation method of a thick gauge copper-steel clad plate, the specific operation steps are:

[0037] Step 1: Use a belt sander to grind the surfaces to be joined and the sides of the copper plate and the steel plate, respectively, to make the polished surface metallic luster, and then use alcohol and acetone to clean the polished surfaces in turn; T1 copper plate and Q235 steel plate are used as the base material of copper-steel composite plate. The specification of T1 copper plate is 400mm×400mm×50mm, and the specification of Q235 steel plate is 400mm×400mm×30mm; the surface roughness Ra≤100μm;

[0038] Step 2: Assemble the treated copper plates and steel plates, then stack them into the working chamber of the vacuum electron beam welding machine, and vacuumize them to 5×10 -3 Pa, and then adopt the welding process of welding speed of 300mm / min and welding electron beam current of 70mA to vacuum-weld and encapsulate the plate; during welding, the position of the b...

Embodiment 3

[0044] A preparation method of a thick gauge copper-steel clad plate, the specific operation steps are:

[0045]Step 1: Use a belt machine to polish the contact surface and side surfaces of the copper plate and steel plate respectively until the surface is metallic luster, and then clean the polished surface with alcohol and acetone in sequence; among them, T2 is selected Copper plate and Q255 steel plate are used as the base material of copper-steel composite plate. The specification of T3 copper plate is 300mm×400mm×25mm, and the specification of Q255 steel plate is 300mm×400mm×35mm; surface roughness Ra≤100μm;

[0046] Step 2: Assemble the treated copper plate and steel plate, and stack them into the working chamber of the vacuum electron beam welding machine, evacuate to 0.1Pa, and then adopt the welding process of welding speed 250mm / min and welding electron beam current 65mA , carry out vacuum welding and packaging on the plate; the position of the beam spot should be of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com