Pesticide microcapsule suspending agent without residual emulsifier and preparation method thereof

A microcapsule suspending agent and emulsifying agent technology, applied in botany equipment and methods, insecticides, biocides, etc., can solve the problems of lack of simple operation and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

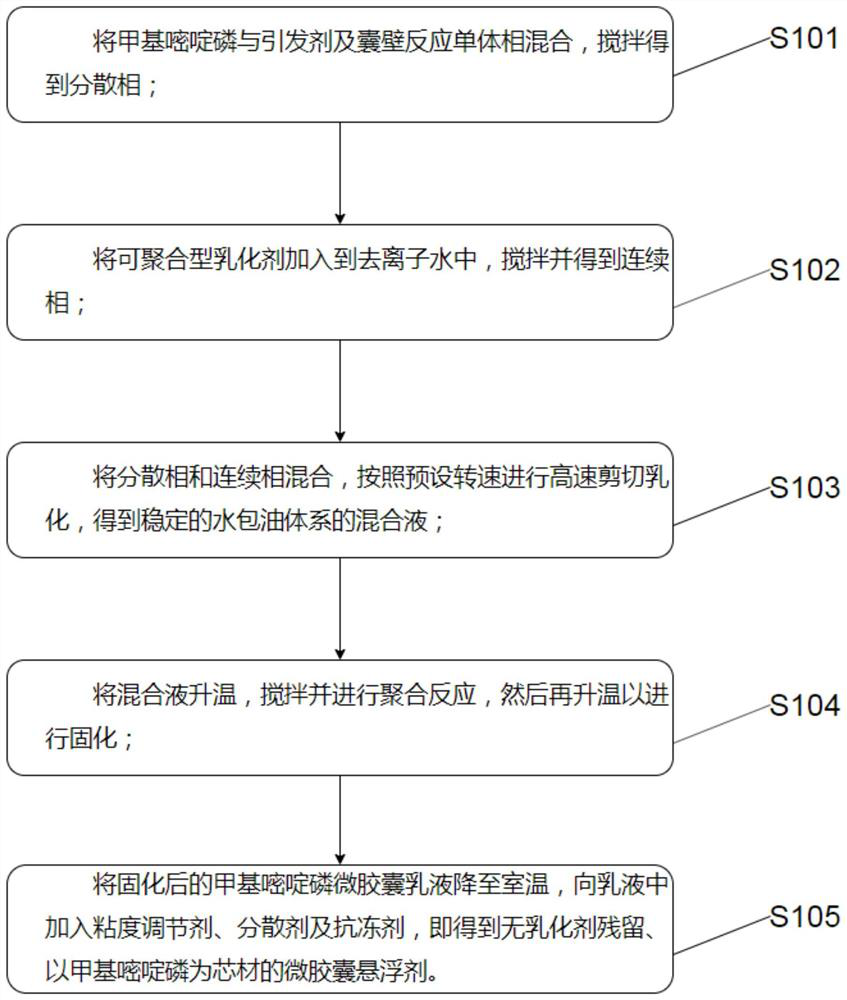

[0033] A preparation method of pesticide microcapsule suspension without residue emulsifier, comprising the steps of:

[0034] S101 mixes pirimiphos-methyl with initiator and capsule wall reaction monomer, and stirs to obtain a dispersed phase;

[0035] Wherein, pirimiphos-methyl and the cyst wall reaction monomer are weighed and proportioned according to the mass ratio of 6:4 to 9:1, and the initiator is 0.5 to 5% of the cyst wall reaction monomer; the above percentages are mass percentages;

[0036] S102 Add a polymerizable emulsifier into deionized water, and stir at 500rpm-2000rpm for 20min to obtain a continuous phase, wherein the polymerizable emulsifier is 0.1%-5% of the continuous phase, and the above percentages are mass percentages;

[0037] S103 Mix the dispersed phase and the continuous phase according to the mass ratio of 1:1 to 1:8, perform high-speed shear emulsification at 10,000 rpm to 20,000 rpm, and the emulsification time is 10 minutes, to obtain a stable m...

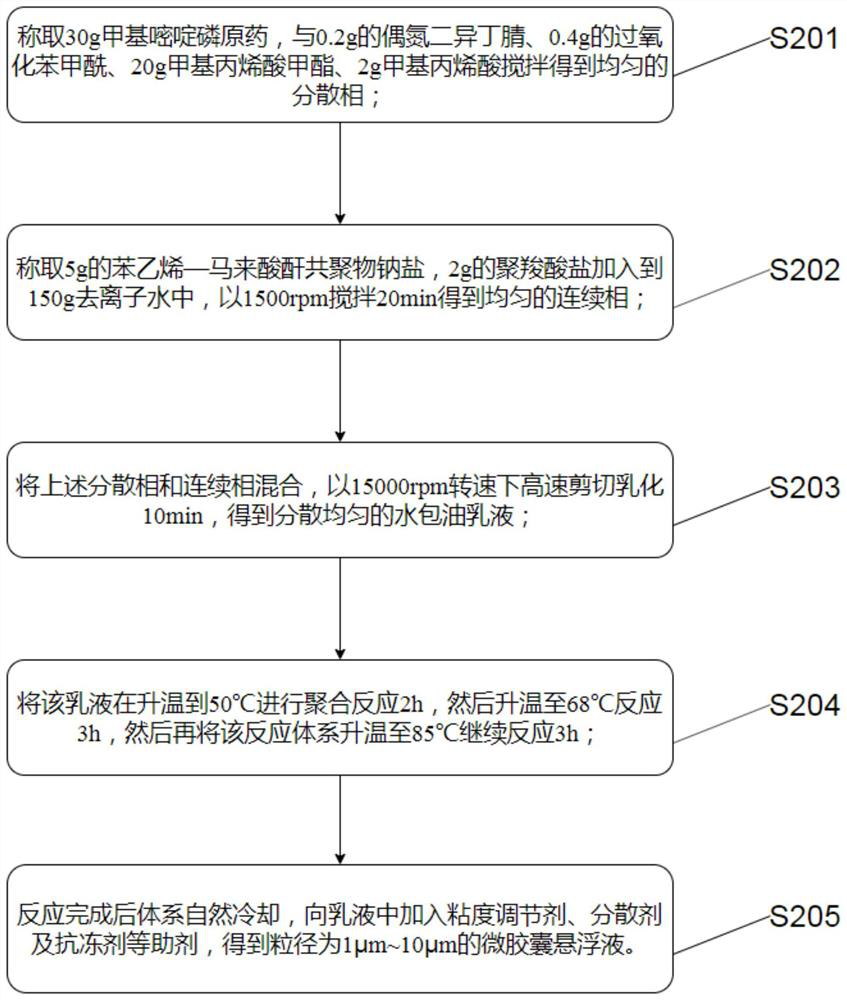

specific Embodiment 1

[0046] S201 Weigh 30g of pirimiphos-methyl technical substance, stir with 0.2g of azobisisobutyronitrile, 0.4g of benzoyl peroxide, 20g of methyl methacrylate, and 2g of methacrylic acid to obtain a uniform dispersed phase; S202 Weigh 5g of styrene-maleic anhydride copolymer sodium salt, add 2g of polycarboxylate into 150g of deionized water, stir at 1500rpm for 20min to obtain a uniform continuous phase; High-speed shear emulsification at a rotating speed for 10 minutes to obtain a uniformly dispersed oil-in-water emulsion; S204 raise the temperature of the emulsion to 50°C for polymerization for 2 hours, then raise the temperature to 68°C for 3 hours, and then raise the temperature of the reaction system to 85°C to continue React for 3 hours; after the S205 reaction is completed, the system is cooled naturally, and additives such as viscosity modifier, dispersant and antifreeze are added to the emulsion to obtain a microcapsule suspension with a particle size of 1 μm to 10 μm...

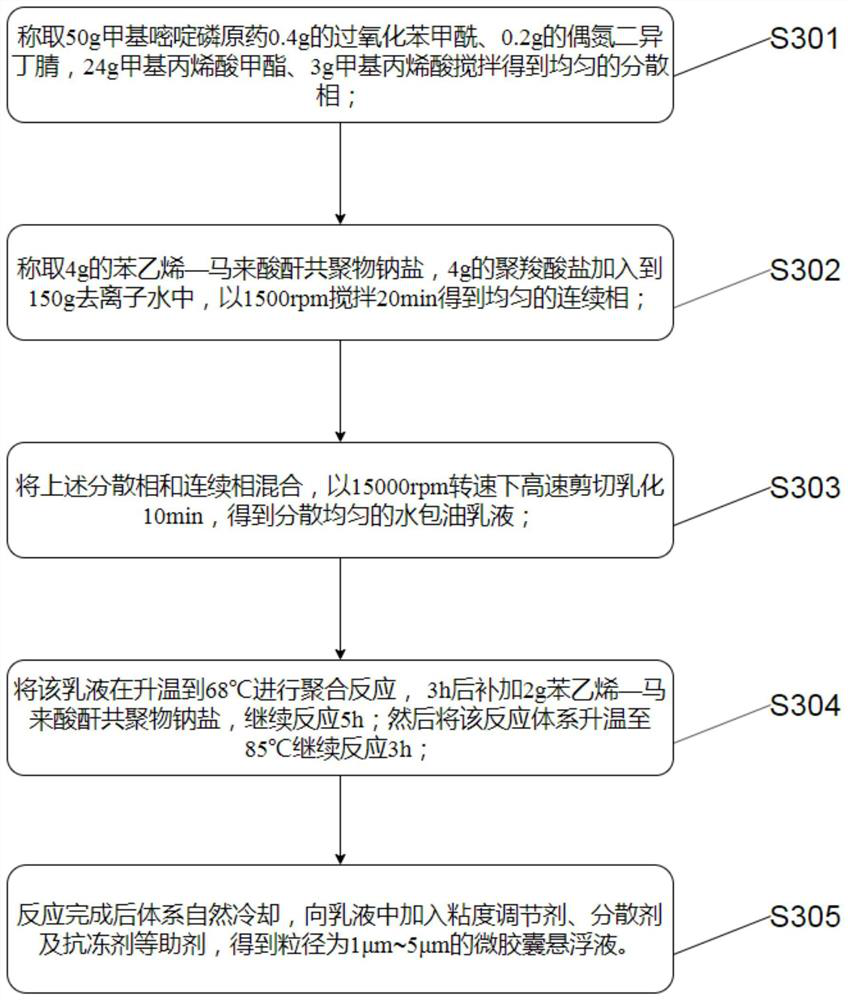

specific Embodiment 2

[0048] S201 weighs 0.4g of benzoyl peroxide, 0.2g of benzoyl peroxide, 0.2g of 50g of pirimiphos-methyl, 24g of methyl methacrylate, and 3g of methacrylic acid and stirs to obtain a uniform dispersed phase; S202 weighs Add 4g of styrene-maleic anhydride copolymer sodium salt, 4g of polycarboxylate into 150g of deionized water, stir at 1500rpm for 20min to obtain a uniform continuous phase; High-speed shearing emulsification for 10 minutes to obtain a uniformly dispersed oil-in-water emulsion; S204 to polymerize the emulsion at 68 ° C, and add 2 g of styrene-maleic anhydride copolymer sodium salt after 3 hours, and continue the reaction for 5 hours; then The temperature of the reaction system is raised to 85°C and the reaction is continued for 3 hours; after the S205 reaction is completed, the system is naturally cooled, and additives such as viscosity modifier, dispersant and antifreeze are added to the emulsion to obtain a microcapsule suspension with a particle size of 1 μm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com