Lignin nitrogen-rich carbon/zinc oxide nanocomposite as well as preparation method and application thereof

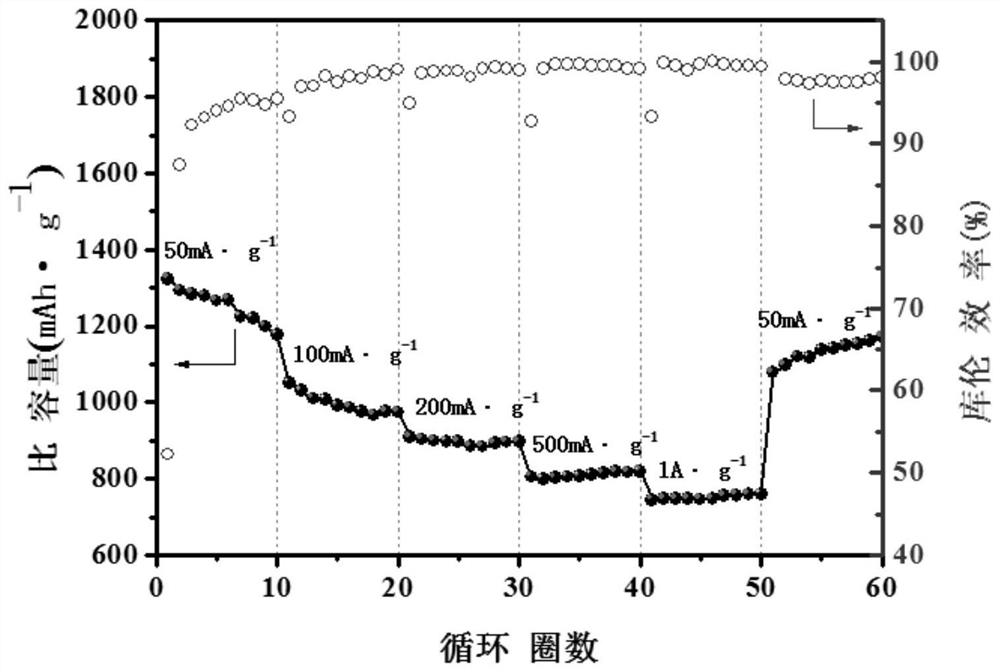

A zinc oxide nano-composite material technology, applied in the field of lignin nitrogen-rich carbon/zinc oxide nano-composite materials and its preparation, can solve the problems of pulverization and capacity attenuation, easy agglomeration of materials, poor rate performance, etc., to achieve faster embedding and prolapse, enhance structural strength, and increase energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Take 10g of purified alkali lignin powder and add it to 190ml of deionized water, add ammonia water while stirring to fully dissolve the lignin, adjust the pH to 12 and stir for 0.5h, then transfer the solution to a hydrothermal kettle, and Place the kettle in an air atmosphere at 180°C and heat it for 9 hours. After cooling down to room temperature, add 0.1 mol / L hydrochloric acid and adjust the pH to 4. Filter the filtrate to obtain an acid-soluble lignin solution.

[0090] Add 1g of zinc chloride and 1g of ammonium carbonate into 198ml of deionized water, ultrasonically disperse for 10min, and then use a peristaltic pump to slowly drop the solution into the acid-soluble lignin solution at a rate of 2mL / min, stirring while adding. Then the mixed solution was transferred to a hydrothermal kettle, and the hydrothermal kettle was placed in an air atmosphere at 120° C. for heating for 2 hours. After it was cooled to room temperature, it was taken out to obtain a low-molecu...

Embodiment 2

[0095]Take 10g of purified enzymatic lignin powder and add it to 90ml of deionized water, add ammonia water while stirring to fully dissolve the lignin, adjust the pH to 12 and stir for 1 hour, then transfer the solution to a hydrothermal kettle, heat the water to Place the kettle in an air atmosphere at 200°C and heat it for 12 hours. After cooling down to room temperature, add 0.1 mol / L acetic acid and adjust the pH to 5. Filter the filtrate to obtain an acid-soluble lignin solution.

[0096] Add 10g of zinc acetate and 10g of ammonium bicarbonate into 380ml of deionized water, ultrasonically disperse for 30min, and then use a peristaltic pump to slowly drop the solution into the acid-soluble lignin solution at a rate of 10mL / min, stirring while adding. Subsequently, the mixed solution was transferred to a hydrothermal kettle, and the hydrothermal kettle was placed in an air atmosphere at 150° C. for heating for 3 hours. After it was cooled to room temperature, it was taken o...

Embodiment 3

[0101] Take 10g of purified organic solvent lignin powder and add it to 157ml of deionized water, add potassium hydroxide while stirring to fully dissolve the lignin, adjust the pH to 12 and stir for 0.5h, then transfer the solution to a hydrothermal kettle, Place the hydrothermal kettle in an air atmosphere at 160°C and heat it for 6 hours. After cooling down to room temperature, add 0.1 mol / L nitric acid and adjust the pH to 3. Filter the filtrate to obtain an acid-soluble lignin solution.

[0102] Add 2g of zinc nitrate and 2g of potassium carbonate into 396ml of deionized water, ultrasonically disperse for 15min, then use a peristaltic pump to slowly drop the solution into the acid-soluble lignin solution at a rate of 3mL / min, and stir while adding. Subsequently, the mixed solution was transferred to a hydrothermal kettle, and the hydrothermal kettle was placed in an air atmosphere at 110° C. for heating for 1.5 h, and was taken out after it dropped to room temperature to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com