Laser cladding iron-based alloy powder for repairing steam turbine rotor journal and preparation and application thereof

An iron-based alloy, laser cladding technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of low dilution rate, excellent bonding strength, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] An iron-based alloy powder for repairing the rotor journal of a 30Cr2Ni4MoV steam turbine, the chemical composition of the iron-based alloy powder is: carbon C: 0.04%, chromium Cr: 1.0%, molybdenum Mo: 0.5%, silicon Si: 0.5% , manganese Mn: 0.6%, boron B: 0.4%, and the balance is Fe.

Embodiment 2

[0061] An iron-based alloy powder for repairing the rotor journal of a 30Cr2Ni4MoV steam turbine, the chemical composition of the iron-based alloy powder is: carbon C: 0.05%, chromium Cr: 1.1%, molybdenum Mo: 0.6%, silicon Si: 0.6% , manganese Mn: 0.7%, boron B: 0%, and the balance is Fe.

Embodiment 3

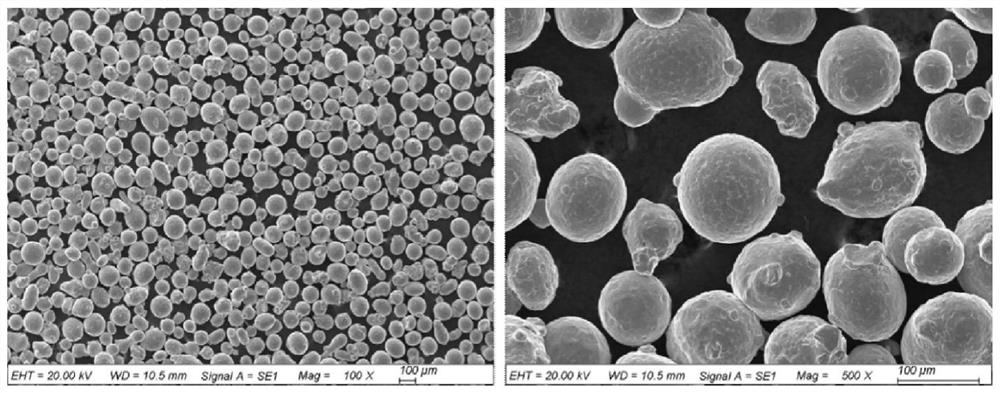

[0063] figure 1 It is a schematic diagram of the principle of gas atomization pulverization, and the above-mentioned preparation method of the iron-based alloy powder for repairing the rotor journal of a 30Cr2Ni4MoV steam turbine, the specific steps are as follows:

[0064] Step 1: Ingredients: Prepare raw materials according to the weight percentage of each component in the laser cladding powder described in Embodiment 1 or 2;

[0065] Step 2: Melting: put the raw materials prepared in Step 1 into an intermediate frequency induction melting furnace for melting to obtain an alloy solution, and keep it in a vacuum holding furnace for 3 hours;

[0066] Step 3: Atomization: further atomize the alloy solution obtained in step 2, the atomization medium is an inert gas at -15°C ~ 5°C, and the atomization pressure is 3-6MPa; after the atomization, in an inert atmosphere at room temperature Down to room temperature, it can be obtained after drying, and the powder is collected and sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com