Preparation method of white cast iron for roller, and white cast iron

A technology of white cast iron and rolling rolls, applied in the field of foundry, can solve the problems of limited rolling capacity, low service life, block drop of the pass shape, etc., and achieve the effect of improving the operation rate of the rolling mill, improving the surface quality, and reducing the number of roll changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

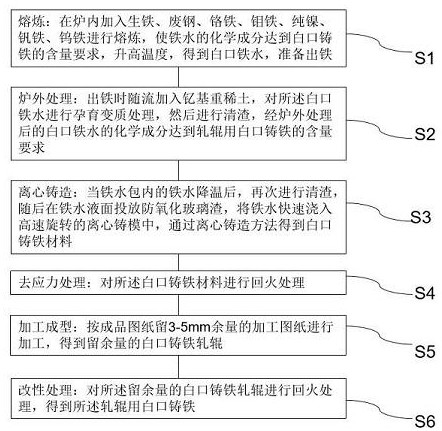

[0028] Such as figure 1 Shown, according to the preparation method of roll white cast iron of the embodiment of the present invention, comprises the following steps:

[0029] S1. Smelting: Add pig iron, scrap steel, ferrochrome, ferromolybdenum, pure nickel, ferrovanadium, and ferrotungsten to the furnace for smelting, so that the chemical composition of the molten iron meets the content requirements of white cast iron, and raise the temperature to obtain white iron , ready to tap; S2, out-of-furnace treatment: adding yttrium-based heavy rare earth along with the flow when tapping, inoculating and modifying the white hot metal, and then cleaning the slag. Content requirements of white cast iron. S3. Centrifugal casting: After the molten iron in the ladle cools down, remove the slag again, then put anti-oxidation glass slag on the liquid surface of the molten iron, quickly pour the molten iron into a high-speed rotating centrifugal mold, and obtain white cast iron by centrifug...

Embodiment 1

[0050] Prepare a 380×650mm hot-rolled 304 stainless steel rod finish rolling white cast iron roll, the target roll white cast iron chemical composition and weight percentage requirements are: C is 3.0-3.5%, Si is 0.7-1.2% , Mn is 0.5-1.5%, P≤0.05%, S≤0.03%, Ni is 2.0-3.0%, Mo is 1.0-2.0%, V is 1.0-2.0%, Cr is 2.0-3.0%, W is 1.0- 2.0%, Re is 0.03-0.07%, and the rest is Fe and unavoidable impurities. Specific steps are as follows:

[0051] (1) Smelting: Add a certain proportion of pig iron, scrap steel, ferrochrome, ferromolybdenum, pure nickel, ferrovanadium, and ferrotungsten to the intermediate frequency furnace for smelting, and the chemical composition and weight percentage of the obtained white cast iron are: C 3.22% for Si, 0.92% for Si, 0.58% for Mn, 0.04% for P, S≤0.029%, 2.3% for Ni, 1.62% for Mo, 1.65% for V, 2.33% for Cr, 1.44% for W, and the rest For Fe and unavoidable impurities. And raise the temperature to 1600°C to obtain white molten iron, keep it warm for 1...

Embodiment 2

[0058] Prepare a 480×700mm hot-rolled 304 stainless steel rod finish rolling white cast iron roll, the target roll white cast iron chemical composition and weight percentage requirements are: C is 3.0-3.5%, Si is 0.7-1.2% , Mn is 0.5-1.5%, P≤0.05%, S≤0.03%, Ni is 2.0-3.0%, Mo is 1.0-2.0%, V is 1.0-2.0%, Cr is 2.0-3.0%, W is 1.0- 2.0%, Re is 0.03-0.07%, and the rest is Fe and unavoidable impurities. Specific steps are as follows:

[0059] (1) Smelting: Add a certain proportion of pig iron, scrap steel, ferrochrome, ferromolybdenum, pure nickel, ferrovanadium, and ferrotungsten to the intermediate frequency furnace for smelting, and the chemical composition and weight percentage of the obtained white cast iron are: C 3.11%, Si 0.77%, Mn 0.73%, P 0.04%, S≤0.026%, Ni 2.7%, Mo 1.36%, V 1.67%, Cr 2.45%, W 1.88%, and the rest For Fe and unavoidable impurities. And raise the temperature to 1600°C to obtain white molten iron, keep it warm for 10 minutes, stop the power supply to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com