Coating liquid for barrier layer, preparation and barrier film thereof

A technology of coating liquid and barrier layer, applied in the direction of coating, etc., can solve the problems affecting the interface compactness of the coating, the gap in gas barrier properties, and the complex process, and achieve excellent oxygen barrier and water barrier properties, excellent gas barrier properties. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

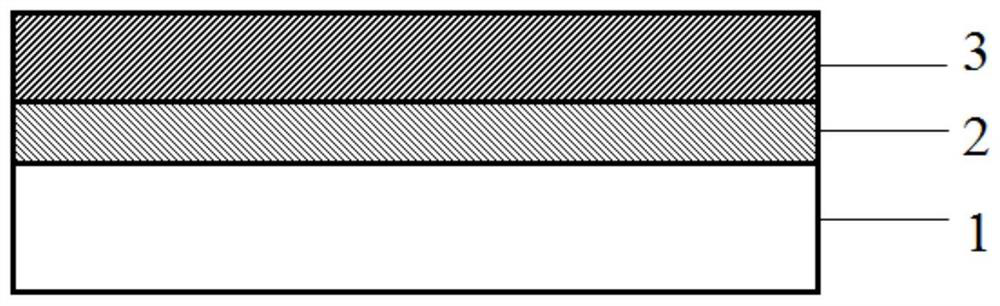

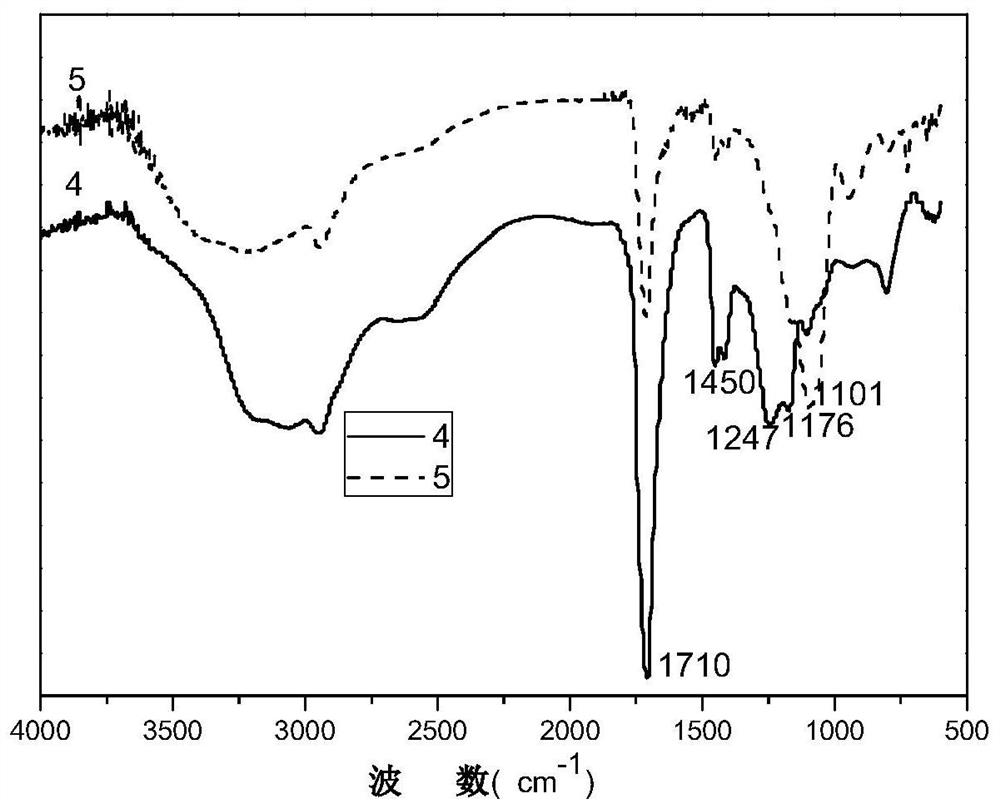

Image

Examples

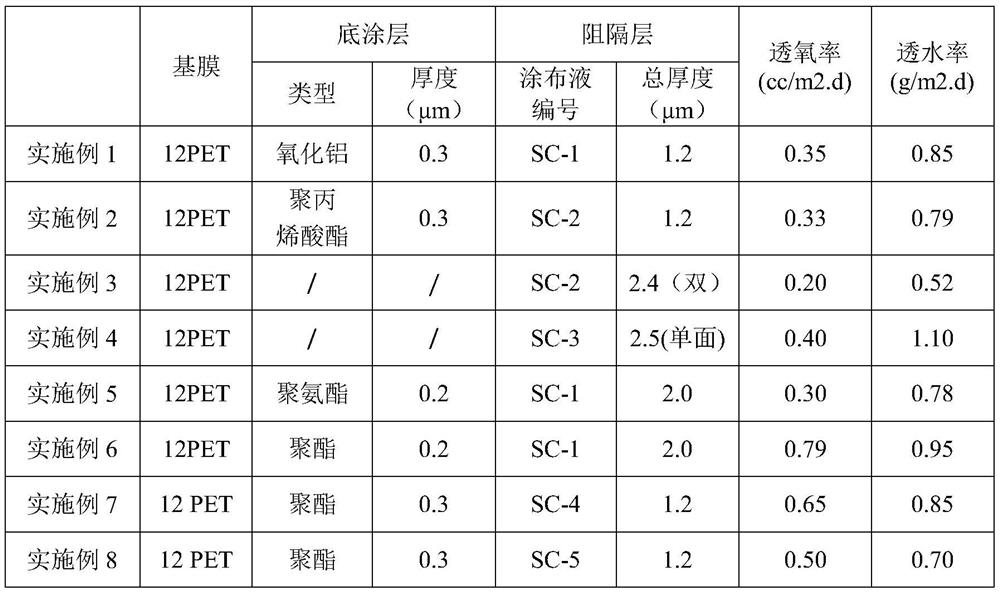

Embodiment 1

[0063] Coating solution preparation for barrier coating:

[0064] 170.0 parts by mass of polyacrylic acid aqueous solution (molecular weight 5000) with a solid content of 20%, 2.5 parts by mass of gamma-aminopropyltriethoxysilane (KH550), polyvinyl alcohol with a solid content of 5% (polymerization degree 2600, degree of alcoholysis 99%) and 170 parts by mass of the three components were uniformly mixed and stirred at 80° C. for 30 minutes at a high speed to obtain ester crosslinking modified polyacrylic acid liquid ZJ-01.

[0065] 32 parts by mass of tetraethoxysilane, 6.6 parts by mass of silane coupling agent (A187), 6.0 parts by mass of dilute hydrochloric acid (0.1% by mass), 260 parts by mass of methanol, and 600 parts by mass of deionized water are mixed evenly, and stirred at a high speed at room temperature A solution of metal alkoxide hydrolysis condensate L-1 is formed.

[0066] Mix 342.5 parts by mass of the polyacrylic acid solution ZJ-01 solution modified by est...

Embodiment 2

[0072] Coating solution preparation for barrier coating:

[0073] 170.0 parts by mass of polyacrylic acid aqueous solution (molecular weight 25000) with a solid content of 20%, 2.5 parts by mass of gamma-aminopropyltriethoxysilane (KH550), polyvinyl alcohol with a solid content of 5% (polymerization degree 2600, degree of alcoholysis 99%) and 90 parts by mass of the three components were uniformly mixed and stirred at 80° C. for 30 minutes at high speed to obtain ester crosslinking modified polyacrylic acid liquid ZJ-02.

[0074] 32 parts by mass of tetraethoxysilane, 6.6 parts by mass of silane coupling agent (A187), 6.0 parts by mass of dilute hydrochloric acid (0.1% by mass), 260 parts by mass of methanol, and 600 parts by mass of deionized water are mixed evenly, and stirred at a high speed at room temperature A solution of metal alkoxide hydrolysis condensate L-1 is formed.

[0075] Mix 262.5 parts by mass of ester-crosslinked polyacrylic acid solution ZJ-02 and 737.5 pa...

Embodiment 3

[0079] Coating solution preparation for barrier coating:

[0080] Prepare coating liquid SC-2 according to the preparation method of embodiment 2

[0081] Preparation of the barrier film:

[0082]The coated surface of the 12μm PET base film is treated with corona or plasma, and SC-2 is coated on both sides of the base film with double-sided coating equipment, and cured at 120°C for 3 minutes to obtain a barrier coating with a total thickness of 2.4μm. Barrier film; remove it after coating and store it dry to obtain a barrier film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com