A kind of lactide ring-opening polymerization catalyst composition and preparation method thereof

A technology of ring-opening polymerization and catalyst, applied in the field of lactide ring-opening polymerization catalyst composition and preparation thereof, can solve the problems of cytotoxicity, influence the performance of polylactic acid products, poor catalyst stability, etc. High ring conversion rate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

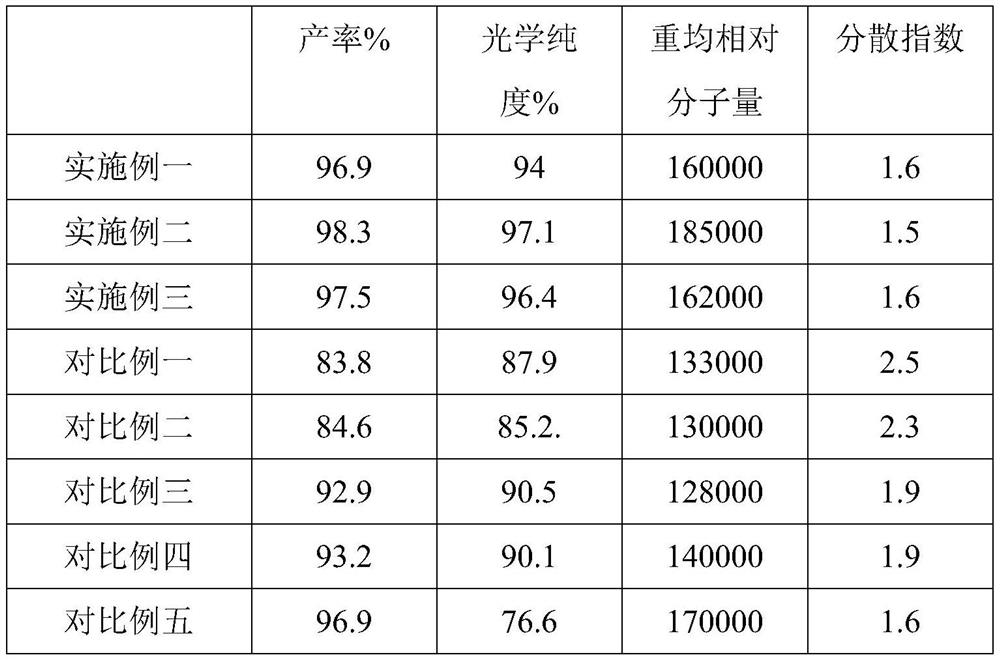

Embodiment 1

[0024]The invention provides a lactide ring opening polymerization catalyst composition, which comprises the following raw materials by weight: 20 parts of zinc oxide, 7 parts of yttrium oxide, 2 parts of triethanolamine, 1 part of n-octacosanol, 2 parts of bis triphenylphosphorus palladium dichloride, 4 parts of triisopropyl methylsilyl trifluoromethane sulfonate, 2 parts of composite decolorizer, 2 parts of activated carbon and 10 parts of activated alumina.

[0025] The preparation method comprises the following steps:

[0026] S1. Dilute and mix the triethanolamine of the specific gravity with water 5 times its total mass by weight, add zinc oxide and yttrium oxide, and vibrate with ultrasonic for 20 minutes to obtain the mixed solution I;

[0027] S2. First add the specific gravity of n-octacosanol and ditriphenylphosphorus palladium dichloride into the mixed solution I, heat up to 78 ℃ while stirring, mix evenly, and then add triisopropyl silyl trifluoromethane sulfonate wit...

Embodiment 2

[0030] The invention provides a lactide ring opening polymerization catalyst composition, which comprises the following raw materials by weight: 28 parts of zinc oxide, 10 parts of yttrium oxide, 3.5 parts of triethanolamine, 5 parts of n-octacosanol, 2.5 parts of bis triphenylphosphorus palladium dichloride, 6 parts of triisopropyl methylsilyl trifluoromethane sulfonate, 3.5 parts of composite decolorizer, 3.5 parts of activated carbon and 15 parts of activated alumina.

[0031] The preparation method comprises the following steps:

[0032] S1. According to the weight part, dilute and mix the triethanolamine with the specific gravity with water 6 times its total mass, add zinc oxide and yttrium oxide, and vibrate with ultrasonic for 25min to obtain the mixed solution I;

[0033] S2. First add the specific gravity of n-octacosanol and ditriphenylphosphorus palladium dichloride into the mixed solution I, heat up to 92 ℃ while stirring, mix evenly, and then add triisopropyl silyl tr...

Embodiment 3

[0036] The invention provides a lactide ring opening polymerization catalyst composition, which comprises the following raw materials by weight: 35 parts of zinc oxide, 15 parts of yttrium oxide, 5 parts of triethanolamine, 12 parts of n-octacosanol, 3 parts of bis triphenylphosphorus palladium dichloride, 8 parts of triisopropyl methylsilyl trifluoromethane sulfonate, 5 parts of composite decolorizer, 5 parts of activated carbon and 20 parts of activated alumina.

[0037] The preparation method comprises the following steps:

[0038] S1. Dilute and mix the triethanolamine of the specific gravity with water 7 times its total mass by weight, add zinc oxide and yttrium oxide, and vibrate with ultrasonic for 30min to obtain the mixed solution I;

[0039] S2. First add the specific gravity of n-octacosanol and ditriphenylphosphorus palladium dichloride into the mixed solution I, heat up to 95 ℃ while stirring, mix evenly, and then add triisopropyl silyl trifluoromethane sulfonate with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com