Flame-retardant GMT ceiling plate and processing method thereof

A sheet and ceiling technology, applied in the field of flame retardant GMT ceiling sheet and its processing, can solve the problems of excessive toxic substances, heavy odor, environmental pollution, etc., and achieve the effect of enhancing adhesion and long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

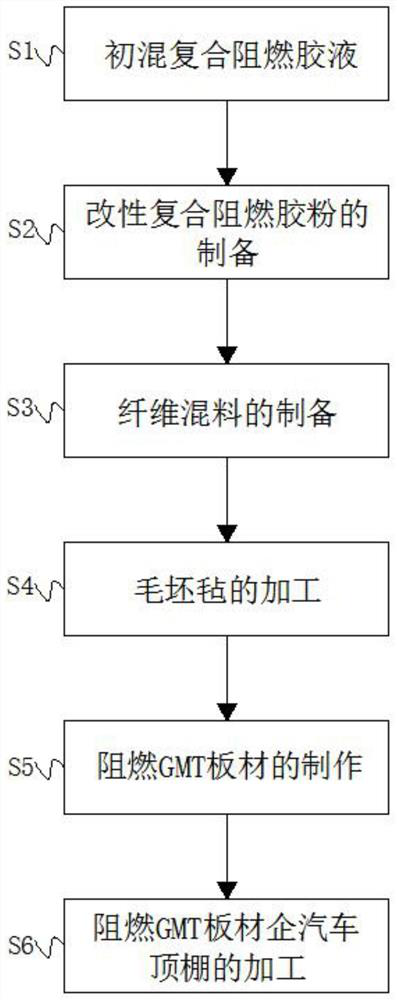

Method used

Image

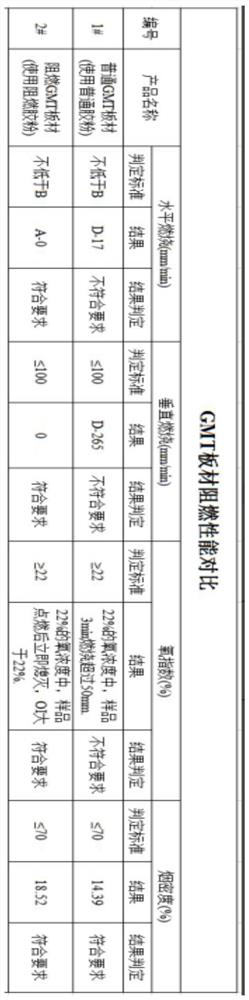

Examples

Embodiment 1

[0032] S1. Initially mixed compound flame retardant glue: First, measure 45 parts of brominated polystyrene, 2 parts of shellac, 2 parts of dextrin, 7 parts of magnesium hydroxide, and 7 parts of hydrogen in corresponding weight ratios by weighing equipment Aluminum oxide, 7 parts of dimethyldichlorosilane and 2 parts of glyceride, and the measured components were poured into a mixing mixer in turn, and stirred for 35 minutes at a speed of 550r / min and a temperature of 28°C, so that The raw materials are fully mixed to complete the initial mixing of the composite flame retardant glue;

[0033] S2. Preparation of modified composite flame retardant rubber powder: Slowly stir the raw material in step S1 at a speed of 350r / min for 1.5h until it dissolves into a gel, then pour the gel composite flame retardant sol into a dryer, and Drying at a temperature of 75°C for 25 minutes, so that the sol is coagulated into a block, and then the block dry sol is crushed by a pulverizer, and s...

Embodiment 2

[0039] S1. Initially mixed compound flame retardant glue: First, measure 40 parts of brominated polystyrene, 1 part of shellac, 1 part of dextrin, 5 parts of magnesium hydroxide, and 5 parts of hydrogen in corresponding weight ratios by weighing equipment Aluminum oxide, 5 parts of dimethyldichlorosilane and 1 part of glyceride, and the measured components were poured into a mixing mixer in turn, and stirred for 30 minutes at a speed of 500 r / min and a temperature of 26 ° C, so that The raw materials are fully mixed to complete the initial mixing of the composite flame retardant glue;

[0040] S2. Preparation of modified composite flame retardant rubber powder: Slowly stir the raw materials in step S1 at a speed of 300r / min for 1 hour until dissolved into a gel, then pour the gel composite flame retardant sol into a dryer, Dry at 75°C for 20 minutes, so that the sol is coagulated into a block, and then the block dry sol is crushed by a pulverizer, and screened through a 100-me...

Embodiment 3

[0046] S1. Initially mixed compound flame retardant glue: First, measure 50 parts of brominated polystyrene, 3 parts of shellac, 3 parts of dextrin, 10 parts of magnesium hydroxide, and 10 parts of hydrogen in corresponding weight ratios by weighing equipment Alumina, 10 parts of dimethyldichlorosilane and 3 parts of glyceride, and the measured components were poured into a mixing mixer in turn, and stirred for 40 minutes at a speed of 600r / min and a temperature of 30°C to make The raw materials are fully mixed to complete the initial mixing of the composite flame retardant glue;

[0047] S2. Preparation of modified composite flame retardant rubber powder: Slowly stir the raw materials in step S1 at a speed of 400r / min for 2 hours until dissolved into a gel, then pour the gel composite flame retardant sol into a dryer, Dry at 80°C for 30 minutes, so that the sol is coagulated into a block, and then the block dry sol is crushed by a pulverizer, and screened through a 110-mesh s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com