High-strength ultrathin integrated proton exchange membrane

A proton exchange membrane and proton exchange technology, applied in the field of electrochemical energy storage, can solve problems such as phase separation, achieve the effects of avoiding phase separation, reducing internal resistance, and ensuring mechanical strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

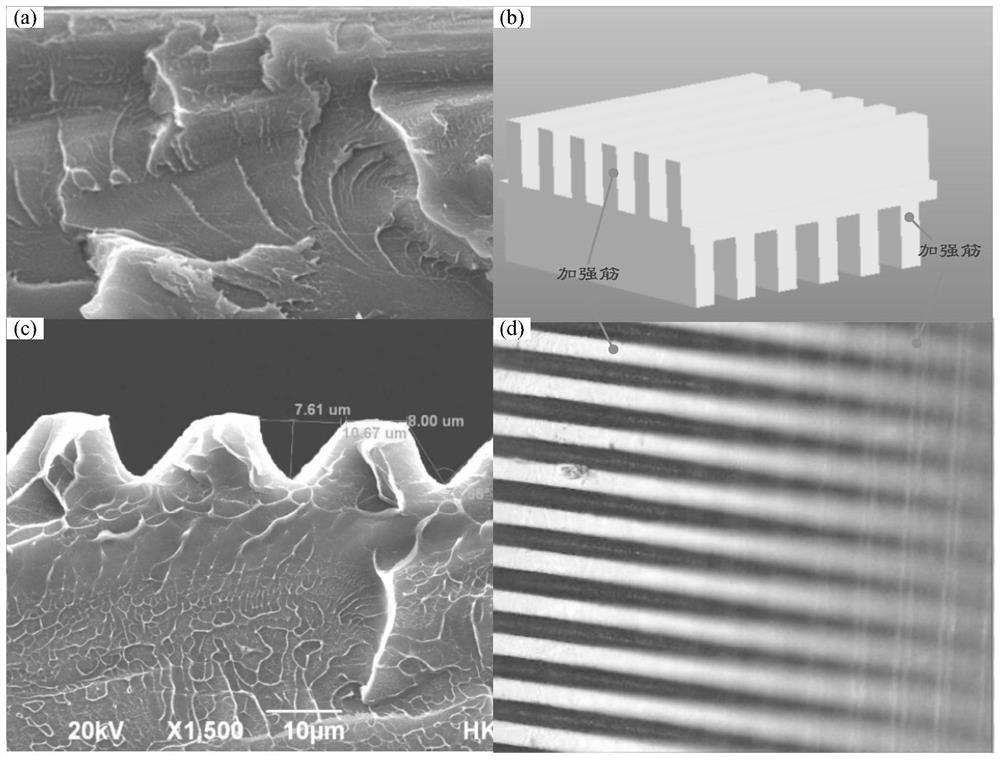

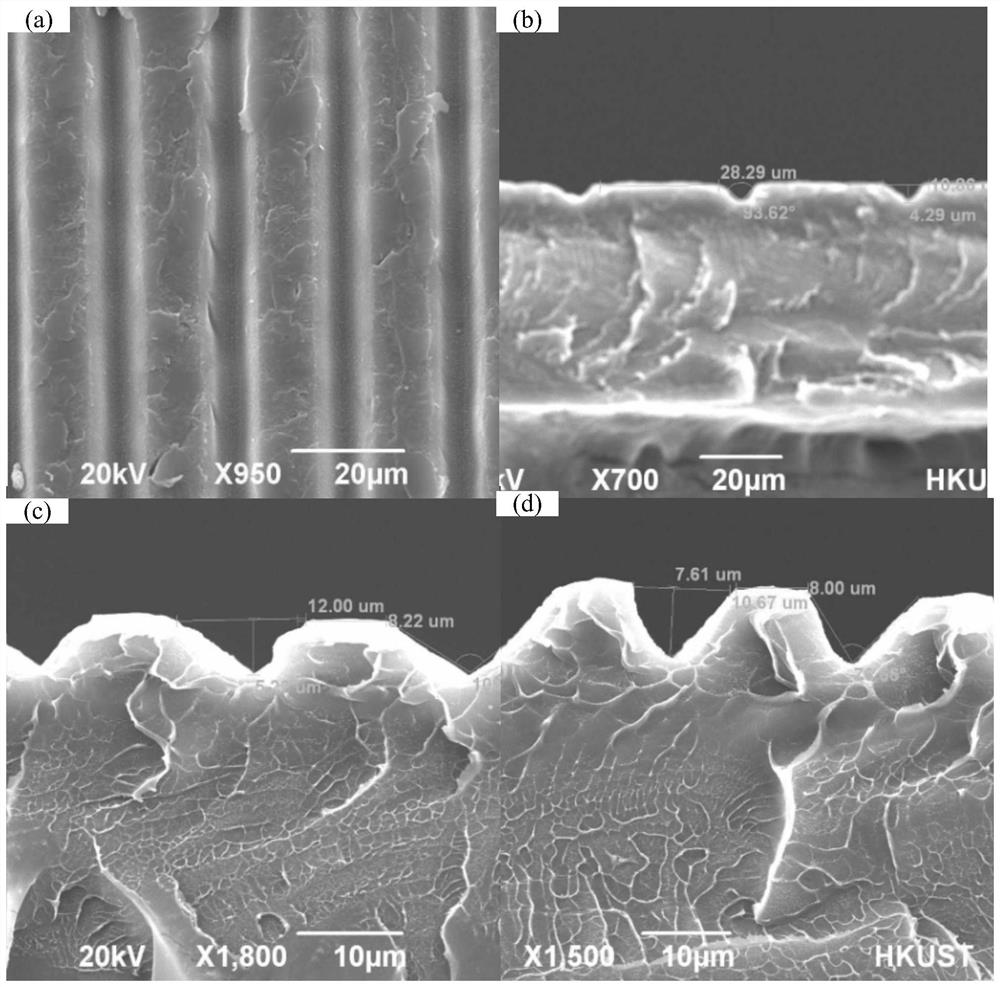

[0042] In this example, the high-strength ultra-thin integrated proton exchange membrane obtained by the above method was subjected to physical characterization, electrochemical detection and battery performance detection. Such as figure 1 As shown, micron-sized rectangular parallelepiped "reinforcing ribs" are processed on the upper and lower sides of the commercial PBI proton exchange membrane, so that the proton exchange membrane is an integral structure composed of the membrane part and the reinforcing ribs on both sides; among them, the rectangular parallelepiped on each side The "reinforcing ribs" are relatively parallel arranged as a supporting layer, the height of the supporting layer is 10-30 μm, the width of each cuboid "reinforcing rib" is 0.1-3 μm, and the gap between two adjacent cuboid "reinforcing ribs" is 0.2-20 μm ; The film part is used as a functional layer, and the thickness of the functional layer is 4-10 μm.

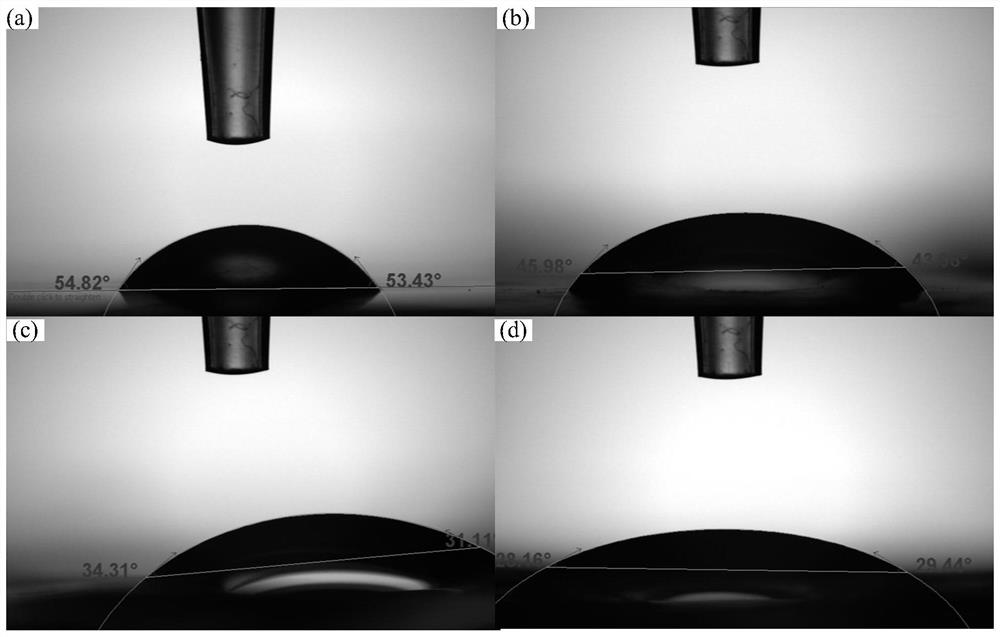

[0043] Such as figure 2 As shown, with the...

Embodiment 2

[0047] The same as in Example 1, except that the commercialized PBI membrane is replaced by other materials or composite membranes of PBI and other materials, such as: composite membranes of PBI and Nafion, PBI membranes and sulfonated polyetheretherketone (sulfonatedpolyetheretherketone) (SPEEK)) composite membrane, PBI and polyacrylonitrile (polyacrylonitrile (PAN)) composite membrane, PBI and sulfonated polyimide (sulfonated polyimide (SPI)) composite membrane, and PBI and polyphenylene sulfone ( Polyphenylene sulfone (PPSU)), polysulfone (polysulfone (PSF)), polyethersulfone (polyethersulfone (PES)), perfluoroether copolymer (polyfluoroether (PFE)), ketone sulfone copolymer (Polyfluoroether ketonesulfone (PAEKS)), Polyether ketone (polyphthalone ether ketone (PEK)), polyvinylidene fluoride (polyvinylidene fluoride (PVDF)), polyimide (polyimide (PI)), polyurethane (polyurethane (PU)), polyvinyl chloride (Polyvinyl Chloride (PVC)), polyvinyl alcohol (PVA), polytetrafluoroeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com