Photochromic thermoplastic polyurethane elastomer material for waterproof and moisture-permeable film, and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

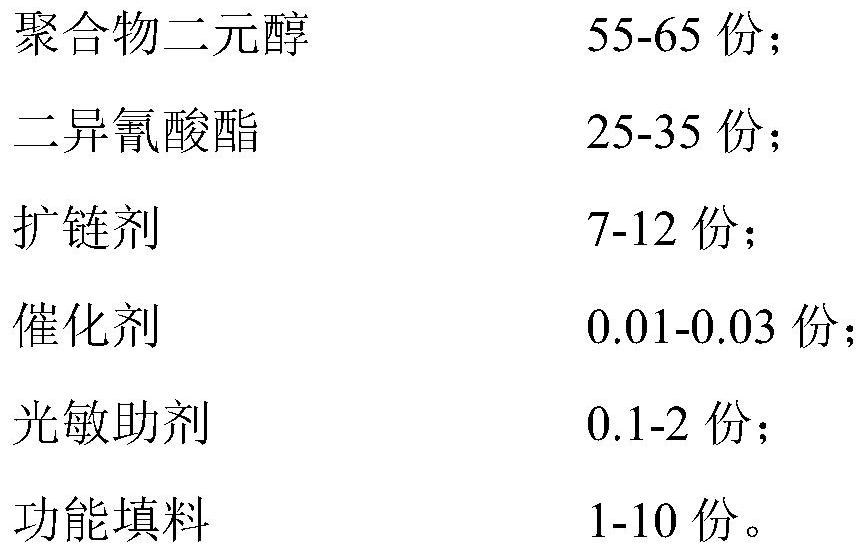

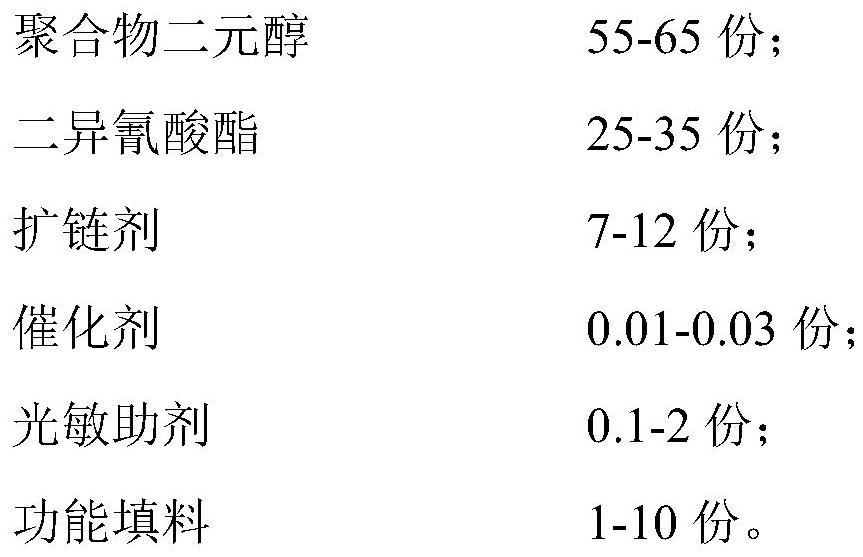

Method used

Image

Examples

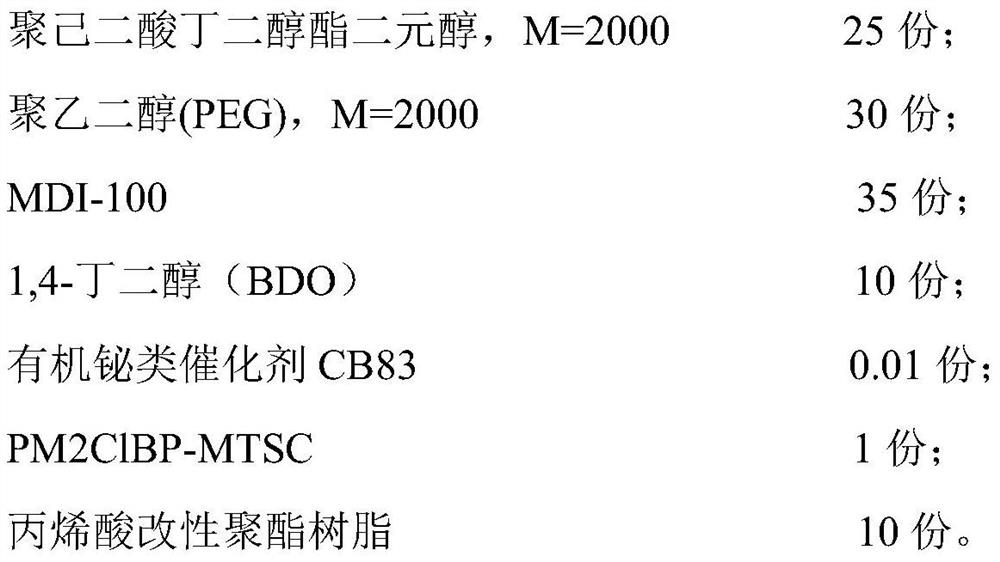

Embodiment 1

[0028] Raw materials and their mass parts are as follows:

[0029]

[0030] (1) After mixing polybutylene adipate diol, PEG, MDI-100, BDO and organic bismuth catalyst CB83, add it to the twin-screw extruder system through a pouring machine.

[0031] (2) Add PM2ClBP-MTSC and acrylic modified polyester resin into the twin-screw extruder system through the feeding perfusion system, and carry out polymerization reaction at 200°C.

[0032] (3) Then the melted polymer is pelletized underwater and dried to obtain thermoplastic polyurethane elastomer material particles for waterproof and moisture-permeable films.

[0033] (4) A polyurethane elastomer film is then obtained by extrusion casting.

Embodiment 2

[0035] Raw materials and their mass parts are as follows:

[0036]

[0037] (1) Mix polyhexamethylene adipate diol, PEG, MDI-100, BDO, organic bismuth catalyst CB83 and add it to the twin-screw extruder system through a pouring machine.

[0038] (2) Add DP3ClBP-PSC and methacrylic acid to the twin-screw extruder system through the feeding perfusion system, and carry out polymerization reaction at 140°C.

[0039] (3) Then the melted polymer is pelletized underwater and dried to obtain thermoplastic polyurethane elastomer material particles for waterproof and moisture-permeable films.

[0040] (4) A polyurethane elastomer film is then obtained by extrusion casting.

Embodiment 3

[0042] Raw materials and their mass parts are as follows:

[0043]

[0044] (1) After mixing polyethylene adipate glycol, PPG, MDI-100, BDO and organic bismuth catalyst CB83, add it to the twin-screw extruder system through a pouring machine.

[0045] (2) Add DP3,4ClBP-ETSC and acrylic acid-modified starch into the twin-screw extruder system through the feeding perfusion system, and carry out polymerization reaction at 240°C.

[0046] (3) Then the melted polymer is pelletized underwater and dried to obtain thermoplastic polyurethane elastomer material particles for waterproof and moisture-permeable films.

[0047] (4) A polyurethane elastomer film is then obtained by extrusion casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com