Explosive continuous preparation system and method based on active micromixer

A mixer and explosive technology, which is used in explosive processing equipment, chemical instruments and methods, explosives, etc., can solve the problems of inability to realize continuous preparation of explosives, and achieve the effects of rapid and continuous particle size distribution, excellent physical chemistry and explosive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

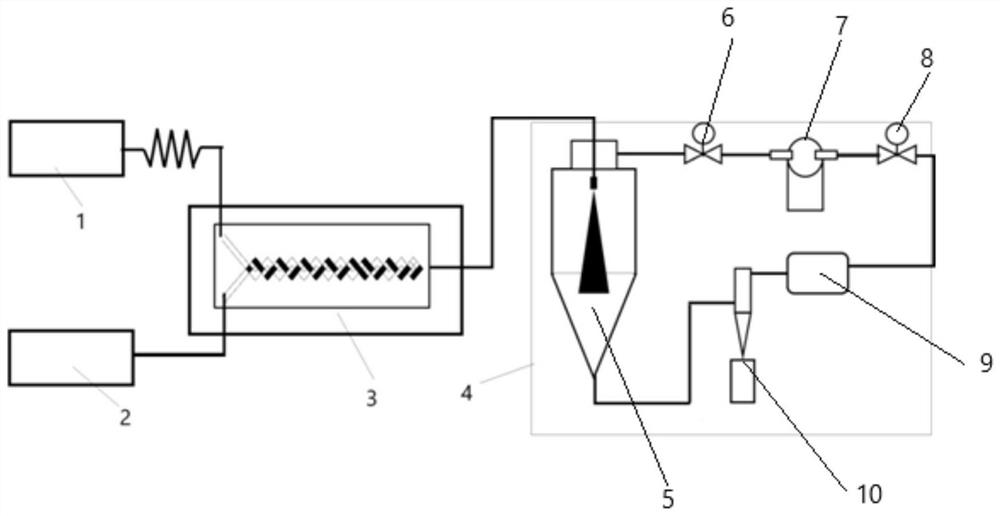

Image

Examples

Embodiment 1

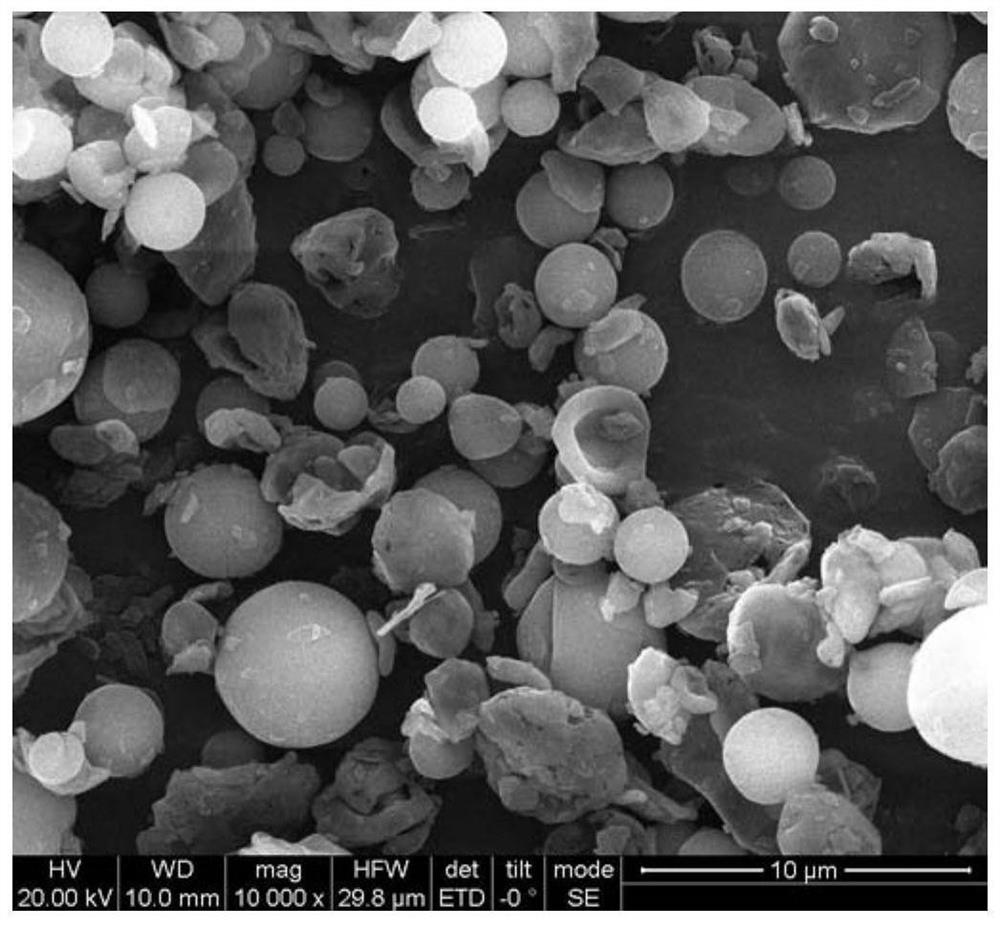

[0042] Embodiment 1: Continuous preparation of hexanitrostilbene

[0043]Hexanitrostilbene explosives were prepared by a continuous explosives preparation system based on microfluidic technology. Hexanitrostilbene explosives were prepared with DMSO as solvent and deionized water as non-solvent. Dissolve 3000mg of HNS in 300mL of DMSO solvent, put it in a bottle, driven by a continuous steady-flow drive device syringe pump, the flow rate is set to 10mL / min, the non-solvent solution is driven by an oscillating drive device, the driving pressure is 340kPa, and the flow rate is 19.8 mL / min. The recrystallization temperature was set at 25 °C. Turn on the drive unit switch, the solvent solution and the non-solvent solution are respectively driven by the steady flow drive device and the oscillating flow drive device, and flow into the vortex mixer, and the solvent and non-solvent are contacted and quickly mixed in the vortex mixer to form hexanitro Stilbene explosive suspension, t...

Embodiment 2

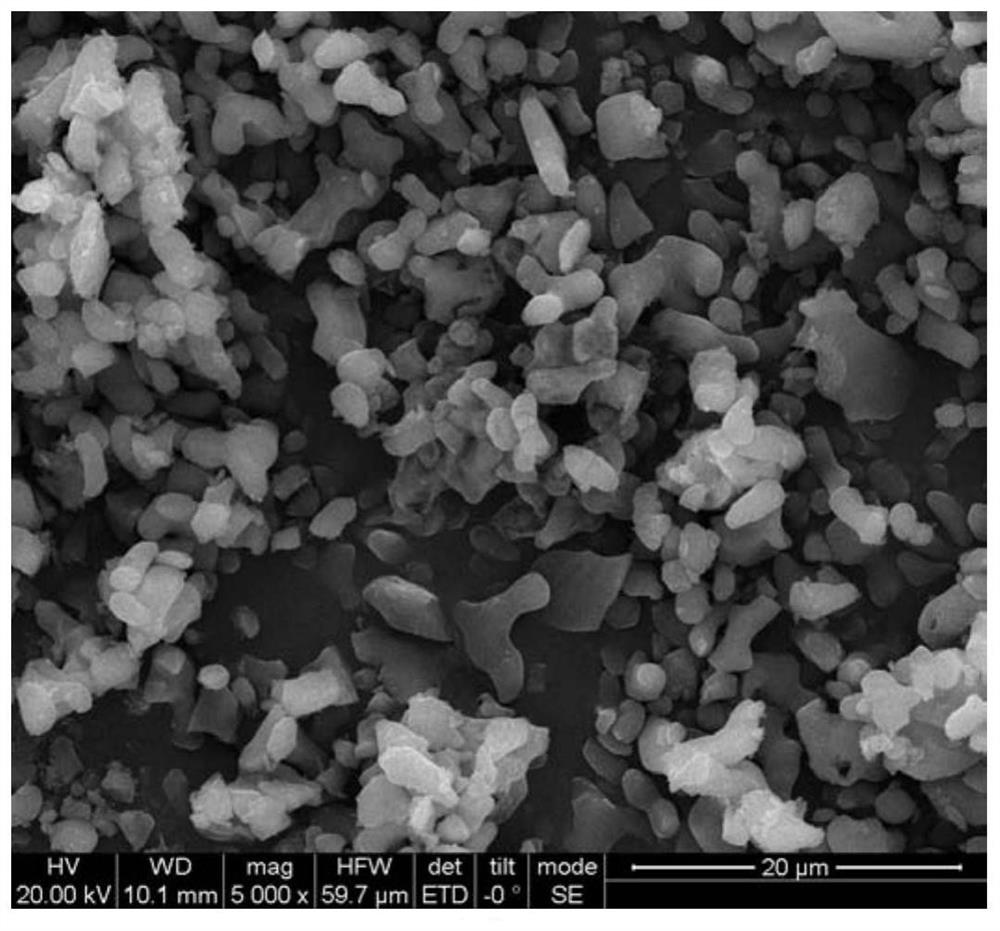

[0044] Embodiment 2: the continuous preparation of RDX

[0045] The continuous preparation system of explosives based on microfluidic technology was used to prepare RDX explosives. Using DMSO as solvent and deionized water as non-solvent to prepare RDX explosive. Dissolve 600mg of HNS in 20mL of DMSO solvent, put it in a bottle, driven by a continuous steady-flow drive device syringe pump, the flow rate is set to 4mL / min, the non-solvent solution is driven by an oscillating drive device, the driving pressure is 340kPa, and the flow rate is 19.8 mL / min. The recrystallization temperature was set at 25 °C. Turn on the drive unit switch, the solvent solution and the non-solvent solution are respectively driven by the steady flow drive device and the oscillating flow drive device, and flow into the vortex mixer, and the solvent and non-solvent are contacted and mixed rapidly in the vortex mixer to form RDX Explosive suspension, the RDX suspension flowing out of the micro-mixer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com