Process for firing ancient building grey tiles in double roasting atmospheres

An ancient building and roasting technology, which is applied in the field of double roasting atmosphere firing of ancient building blue tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

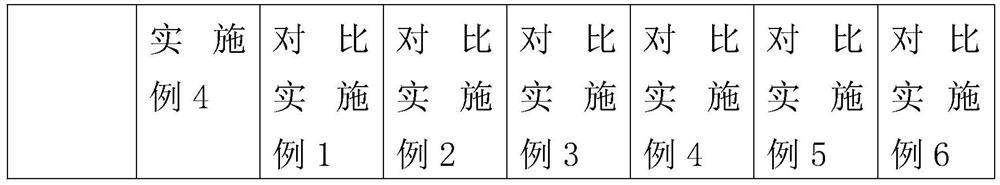

Examples

Embodiment 1

[0029] A process for firing blue tiles of ancient buildings in a double roasting atmosphere, comprising the following steps:

[0030] (1) Weigh the raw materials:

[0031] Weigh the following raw materials according to the corresponding parts by weight: 20 parts of bauxite, 10 parts of purple sandstone, 40 parts of river sand, 15 parts of coal gangue, 8 parts of lime, 0.5 parts of colorant, 2 parts of nano-titanium dioxide, 5 parts of garnet, 0.1 part of The described colorant is iron oxide black; The described additive is lanthanum nitrate, yttrium oxide, ferrocene correspondingly mixed according to weight ratio 4:2:1;

[0032] (2) Ball milling treatment:

[0033] All raw materials weighed in step (1) are collectively put into the ball mill for ball milling, and after completion, the ball mill pulverized material is obtained after taking out a 200-mesh sieve;

[0034] (3) Green body preparation:

[0035] Add clear water to the ball mill pulverized material obtained in step...

Embodiment 2

[0044] A process for firing blue tiles of ancient buildings in a double roasting atmosphere, comprising the following steps:

[0045] (1) Weigh the raw materials:

[0046] Weigh the following raw materials according to the corresponding parts by weight: 20 parts of bauxite, 13 parts of purple sandstone, 42 parts of river sand, 15 parts of coal gangue, 8 parts of lime, 0.5 parts of colorant, 3 parts of nano-titanium dioxide, 7 parts of garnet, 0.2 The described colorant is iron oxide black; The described additive is lanthanum nitrate, yttrium oxide, ferrocene correspondingly mixed according to weight ratio 5:2:1;

[0047] (2) Ball milling treatment:

[0048] All raw materials weighed in step (1) are collectively put into the ball mill for ball milling, and after completion, the ball mill pulverized material is obtained after taking out a 200-mesh sieve;

[0049] (3) Green body preparation:

[0050] Add clear water to the ball mill pulverized material obtained in step (2), fu...

Embodiment 3

[0059] A process for firing blue tiles of ancient buildings in a double roasting atmosphere, comprising the following steps:

[0060] (1) Weigh the raw materials:

[0061] The following raw materials were weighed in corresponding parts by weight: 23 parts of bauxite, 12 parts of purple sandstone, 44 parts of river sand, 18 parts of coal gangue, 10 parts of lime, 1 part of colorant, 3 parts of nano-titanium dioxide, 7 parts of garnet, 0.2 The described colorant is iron oxide black; The described additive is lanthanum nitrate, yttrium oxide, ferrocene correspondingly mixed according to weight ratio 5:2.6:2;

[0062] (2) Ball milling treatment:

[0063] All raw materials weighed in step (1) are collectively put into the ball mill for ball milling, and after completion, the ball mill pulverized material is obtained after taking out a 200-mesh sieve;

[0064] (3) Green body preparation:

[0065] Add clear water to the ball mill pulverized material obtained in step (2), fully sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com